Advanced alkyne deep desorption device and process method in acetylene concentration process

An acetylene and advanced technology, applied in the field of advanced acetylene deep desorption devices, can solve the problems of high energy consumption, good desorption effect, and complicated equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

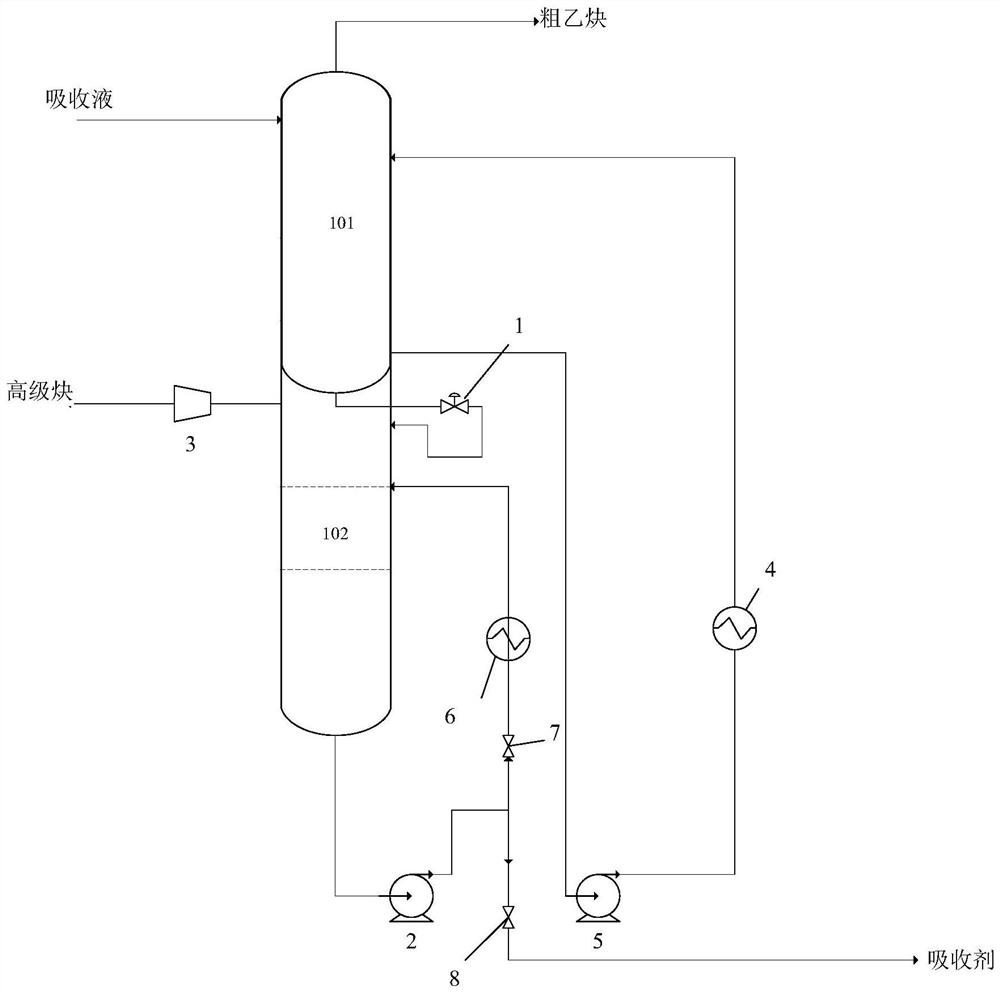

[0035] A high-level alkyne deep desorption device in the process of acetylene concentration, its structure is as follows figure 1 As shown, a high-level alkyne deep desorption device in the acetylene concentration process includes a desorption tower; the desorption tower is separated into two parts in the height direction: the upper part is the upper desorption tower 101, and the lower part is the lower desorption tower 102, The bottom of the upper stage desorption tower 101 is communicated with the top of the lower stage desorption tower 102, and is preferably provided with a first valve 1 on the communication pipeline; the specific structure of each section is as follows:

[0036] The upper desorption tower 101 has a liquid inlet, a crude acetylene gas collection port, a lower outlet, and a top inlet; the lower desorption tower 102 is provided with a high-grade acetylene gas collection port, a bottom outlet, and a top inlet; the crude acetylene mentioned herein means that the...

Embodiment 2

[0038] A kind of advanced alkyne deep desorption process in the acetylene concentration process, using the device described in the embodiment, the process is as follows figure 1 shown, including the following steps:

[0039] The absorption liquid that contains crude acetylene (the main components are acetylene and carbon dioxide) and higher alkynes such as propyne and diacetylene is provided by the liquid inlet of the upper section desorption tower 101 (preferably the liquid inlet is arranged on the upper section of the desorption tower 101 top to increase the The desorption time in body) enters, and the pressure of setting up desorption column 101 is 0.018MPa, and temperature is 88 ℃ (temperature and pressure are controlled by pressure and temperature device respectively), keep the second circulating pump 5 and the second heater 4 In the open state, the absorption liquid is gradually desorbed out of the gas in the continuous circulation; under the action of this pressure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com