Special hot rolling production method for 6-series automobile plate

A production method and automotive technology, applied in metal rolling, temperature control and other directions, can solve the problems of not meeting the technical requirements of customers, and achieve the effect of good product quality, stable performance and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

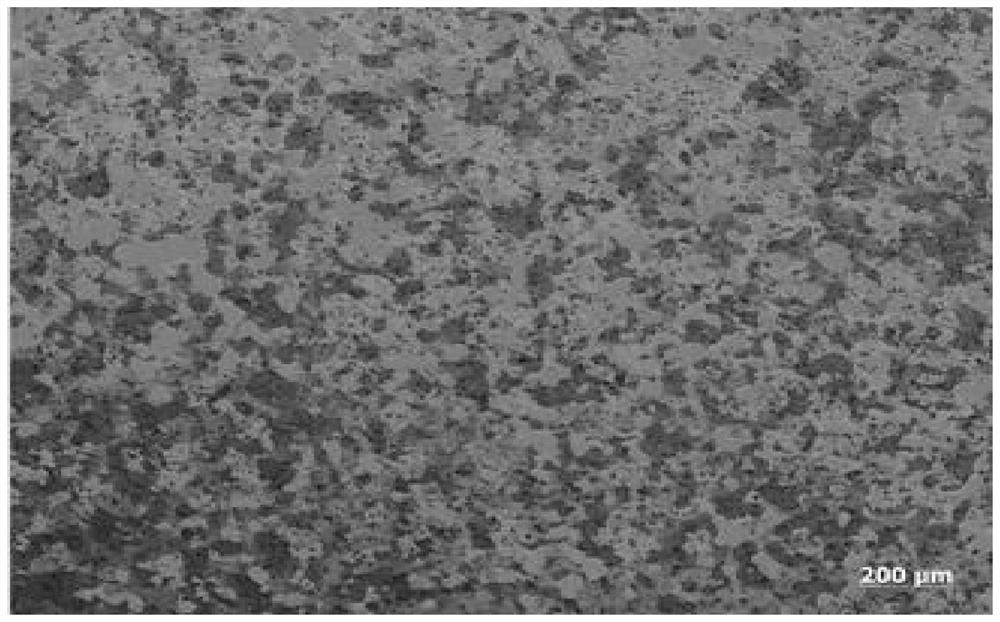

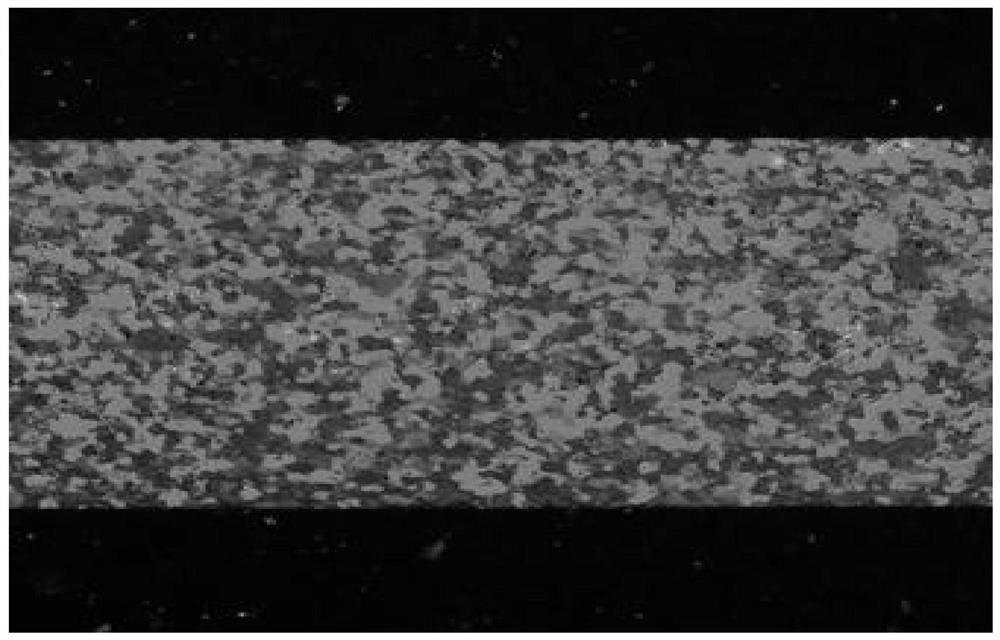

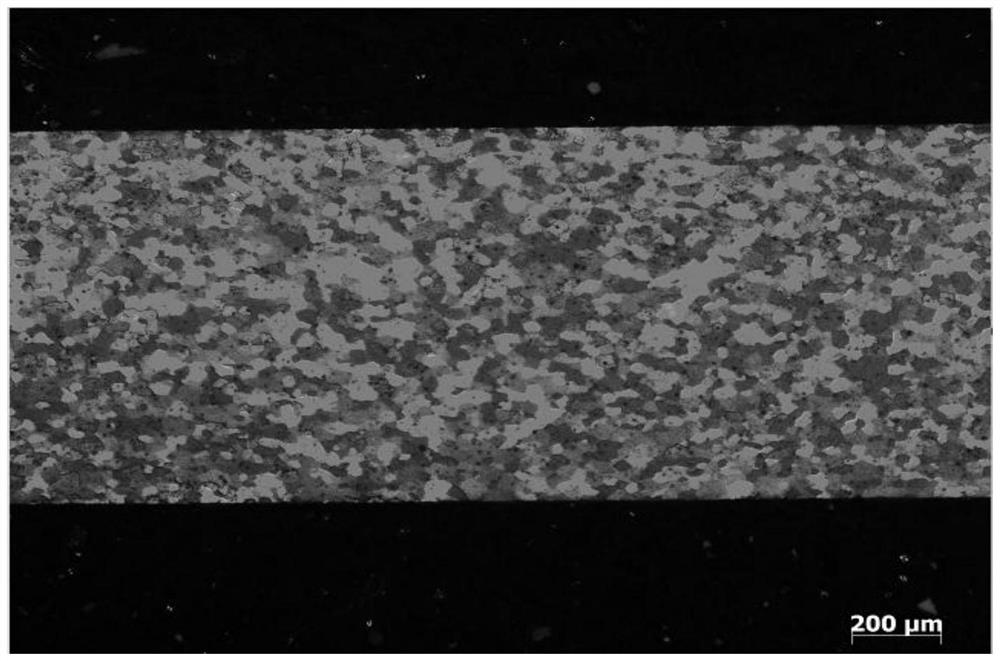

Image

Examples

Embodiment 1

[0028] Step 1: Melting and casting: put the raw materials into the smelting furnace for preheating, the preheating temperature is 400°C, the preheating time is 40 minutes, heat the preheated raw materials, and add an appropriate amount of master alloy, the heating temperature is 630°C, the heating time 150min; transfer the melted molten metal to the holding furnace for refining and slag removal, the refining temperature is 700°C, and the refining time is 20min; the qualified molten aluminum is cast according to the specified process, the casting temperature is 660°C, and the casting speed is 40mm / min;

[0029] Step 2: Face milling of the large flat ingot, the milling method is four-side milling or eight-side milling, the large face milling amount is 10mm, and the small face milling amount is 3mm;

[0030] Step 3: Homogenization treatment of the large slab: the homogenization treatment temperature is 500°C, and the holding time is 2h;

[0031] Step 4: hot rolling: the final t...

Embodiment 2

[0034] Step 1: Melting and casting: put the raw materials into the smelting furnace for preheating, the preheating temperature is 450°C, the preheating time is 50 minutes, heat the preheated raw materials, and add an appropriate amount of master alloy, the heating temperature is 700°C, the heating time 175min; transfer the melted molten metal to the holding furnace for refining and slag removal, the refining temperature is 730°C, and the refining time is 55min; the qualified molten aluminum is cast according to the specified process, the casting temperature is 690°C, and the casting speed is 50mm / min;

[0035] Step 2: Face milling of the large flat ingot, the milling method is four-side milling or eight-side milling, the milling amount of the large face is 18mm, and the milling amount of the small face is 9mm;

[0036] Step 3: Homogenization treatment of the large slab: the homogenization treatment temperature is 550°C, and the holding time is 11h;

[0037] Step 4: hot rolli...

Embodiment 3

[0040] Step 1: Melting and casting: put the raw materials into the smelting furnace for preheating, the preheating temperature is 500°C, the preheating time is 60 minutes, heat the preheated raw materials, and add an appropriate amount of master alloy, the heating temperature is 775°C, the heating time 200min; transfer the melted molten metal to the holding furnace for refining and slag removal, the refining temperature is 760°C, and the refining time is 90min; the qualified molten aluminum is cast according to the specified process, the casting temperature is 720°C, and the casting speed is 60mm / min;

[0041] Step 2: Face milling of the large flat ingot, the milling method is four-sided milling or eight-sided milling, the milling amount of the large face is 25mm, and the milling amount of the small face is 15mm;

[0042] Step 3: Large slab homogenization treatment: the homogenization treatment temperature is 600°C, and the holding time is 20h;

[0043] Step 4: hot rolling: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com