Polyolefin VOC (volatile organic compound) improved filler, preparation method thereof and polyolefin composite material

A composite material, polyolefin technology, applied in the direction of titanium oxide/hydroxide, magnesium oxide, titanium dioxide, etc., can solve the problems of inability to meet environmental protection requirements and high VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

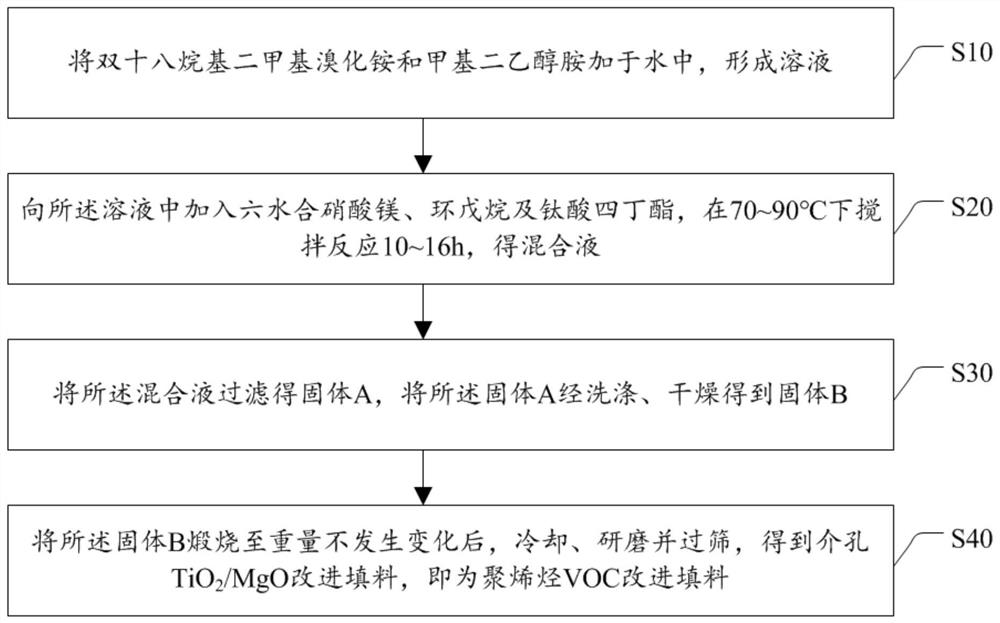

[0031] see figure 1 , the preparation method of polyolefin VOC improved filler that the present invention proposes, comprises the following steps:

[0032] S10, adding dioctadecyldimethylammonium bromide and methyldiethanolamine to water to form a solution.

[0033] In this step, the role of dioctadecyldimethylammonium bromide is a surfactant, which is attached to the prepared mesoporous TiO 2 / MgO improves the surface of the filler particles and modifies the surface so that the mesoporous TiO 2 / MgO improved packing is easy to adsorb VOC; methyldiethanolamine is used to provide an alkaline environment, and the present invention does not limit the ratio of the above-mentioned dioctadecyldimethylammonium bromide, methyldiethanolamine and water, preferably Specifically, the mass ratio of dioctadecyldimethylammonium bromide, methyldiethanolamine and water is (20-30): (10-16): (80-120). Within the above range, the obtained polyolefin VOC-improving filler has a uniform particle ...

Embodiment 1

[0064] 1. Preparation of polyolefin VOC improved filler

[0065] 1) 200g of dioctadecyldimethylammonium bromide, 100g of methyldiethanolamine and 800g of deionized water were uniformly mixed to obtain a mixture, and the mixture was ultrasonicated for 2 hours to obtain a solution;

[0066] 2) Add 400 g of magnesium nitrate hexahydrate, 80 g of cyclopentane and 500 g of tetrabutyl titanate to 300 g of the solution, stir and react at 70° C. for 10 h to obtain a mixed solution;

[0067] 3) filtering the mixed solution to obtain solid A, washing and drying the solid A to obtain solid B;

[0068] 4) Calcining the solid B at 460°C for 10h, cooling, grinding and passing through a 600-mesh sieve to obtain mesoporous TiO 2 / MgO improved filler, that is, polyolefin VOC improved filler.

[0069] 2. Preparation of polyolefin composite materials

[0070] Add 10 parts of the prepared polyolefin VOC-improving filler to 90 parts of polypropylene (PP), stir for 10 minutes through a high-spee...

Embodiment 2

[0073] 1. Preparation of polyolefin VOC improved filler

[0074] 1) Mix 300g of dioctadecyldimethylammonium bromide, 160g of methyldiethanolamine and 1200g of deionized water to obtain a mixture, and ultrasonicate the mixture for 4 hours to obtain a solution;

[0075] 2) Add 500 g of magnesium nitrate hexahydrate, 120 g of cyclopentane and 600 g of tetrabutyl titanate to 400 g of the solution, stir and react at 90°C for 16 hours to obtain a mixed solution;

[0076] 3) filtering the mixed solution to obtain solid A, washing and drying the solid A to obtain solid B;

[0077] 4) Calcining the solid B at 520°C for 12h, cooling, grinding and passing through a 500-mesh sieve to obtain mesoporous TiO 2 / MgO improved filler, that is, polyolefin VOC improved filler.

[0078] 2. Preparation of polyolefin composite materials

[0079] 20 parts of the prepared polyolefin VOC improved filler were added to 80 parts of polybutylene terephthalate (PBT), stirred for 10 minutes by a high mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com