Light conversion film capable of improving efficiency of silicon solar cell and preparation and application thereof

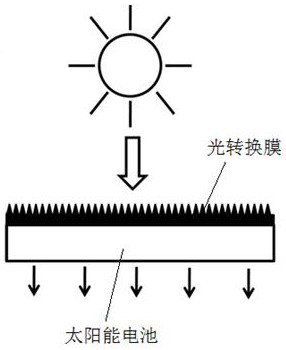

A technology for silicon solar cells and light conversion films, which can be applied in sustainable manufacturing/processing, circuits, electrical components, etc., and can solve the problems of small refractive index, unsuitable for mass production, and more outgoing light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

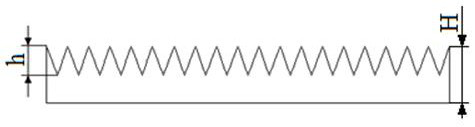

[0033] Weigh 10.0g of glue A and 10.0g of glue B in epoxy resin AB glue, and weigh 0.2g of commercial red phosphor CaAlSiN 3 :Eu 2+ (Powder-to-glue ratio is 1:100) Put it into a vacuum degassing machine and vacuumize and stir for 3 minutes to obtain a rubber powder mixture; make a barrel-shaped cuboid mold with a length of 5 cm, a width of 4 cm, and a height of 1 cm with the film used for the copier ; Use transparent plastic film to make a sheet with a length of 5 cm and a width of 4 cm. One end face of the sheet has a saw-toothed structure, and the saw-toothed structure is composed of a plurality of saw-toothed "V" shaped longitudinal sections arranged side by side. Composition, the height of the sawtooth is greater than 0.5mm, and the angle between the inclined surface and the horizontal plane in the sawtooth is 70°; put the rubber powder mixture in the oven for 20 minutes and pre-dry it, and put the thin slice on the upper surface of the semi-solidified mixture, so that Th...

Embodiment 2

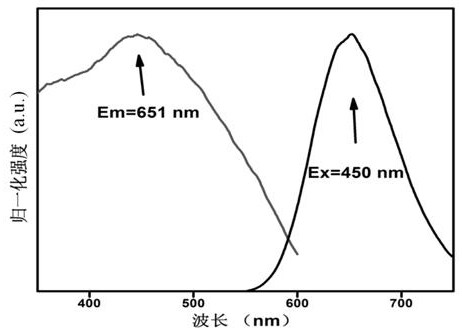

[0050] Weigh 10.0g of glue A and 10.0g of glue B in the epoxy resin AB glue, and weigh 0.222g of red fluorescent powder Y 2 BaAl 4 SiO 12 : Ce 3+ ,Cr 3+ (Powder-to-glue ratio is 1:90) Put it into a vacuum degassing machine and vacuumize and stir for 3 minutes to obtain a rubber powder mixture; use a film for a copier to make a barrel-shaped cuboid mold with a length of 5 cm, a width of 4 cm, and a height of 1 cm ; Use transparent plastic film to make a sheet with a length of 5 cm and a width of 4 cm. One end face of the sheet has a saw-toothed structure, and the saw-toothed structure is composed of a plurality of saw-toothed "V" shaped longitudinal sections arranged side by side. Composition, the height of the sawtooth is greater than 0.5mm, and the angle between the inclined surface and the horizontal plane in the sawtooth is 70°; put the rubber powder mixture in the oven for 20 minutes and pre-dry it, and put the thin slice on the upper surface of the semi-solidified mixt...

Embodiment 3

[0053] Weigh 10.0g of glue A and 10.0g of glue B in epoxy resin AB glue, and weigh 0.182g of red phosphor Sr 4 al 14 o 25 :Mn 4+ (Powder-to-glue ratio is 1:110) Put it into a vacuum degassing machine and vacuumize and stir for 3 minutes to obtain a rubber powder mixture; make a barrel-shaped cuboid mold with a length of 5 cm, a width of 4 cm, and a height of 1 cm with the film used for the copier ; Use transparent plastic film to make a sheet with a length of 5 cm and a width of 4 cm. One end face of the sheet has a saw-toothed structure, and the saw-toothed structure is composed of a plurality of saw-toothed "V" shaped longitudinal sections arranged side by side. Composition, the height of the sawtooth is greater than 0.5mm, and the angle between the inclined surface and the horizontal plane in the sawtooth is 70°; put the rubber powder mixture in the oven for 20 minutes and pre-dry it, and put the thin slice on the upper surface of the semi-solidified mixture, so that The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com