Laser melting deposition forming ultrasonic workbench

A laser melting deposition, workbench technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve problems such as mechanical anisotropy of materials, reduce residual stress, improve various properties, fine The effect of crystallizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

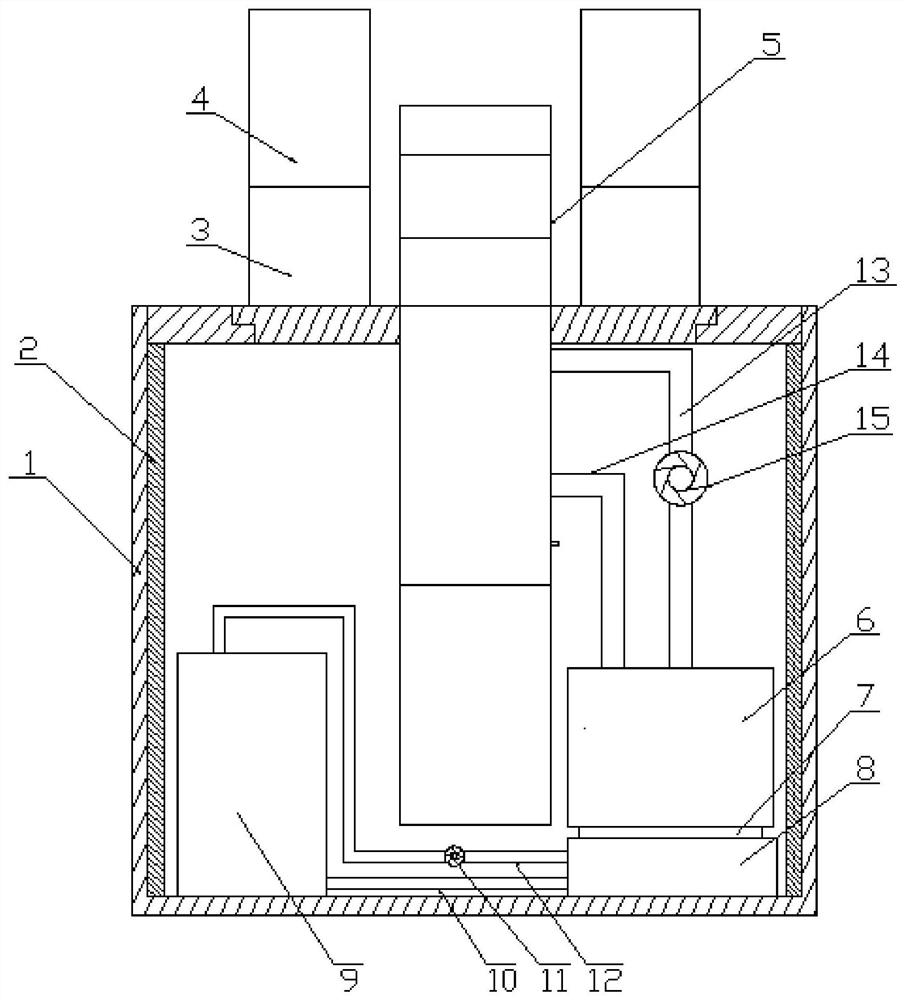

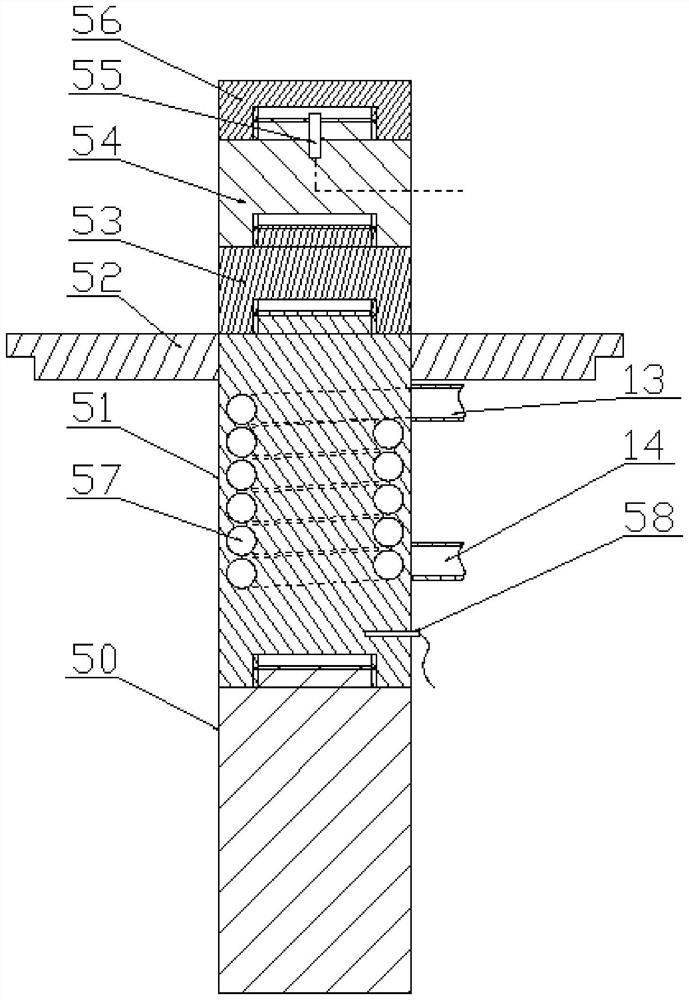

[0015] Specific Embodiment 1: In this embodiment, the laser melting deposition forming ultrasonic workbench is composed of a workbench box 1, several infrared heaters 4, several lifting platforms 3 and ultrasonic vibrators 5;

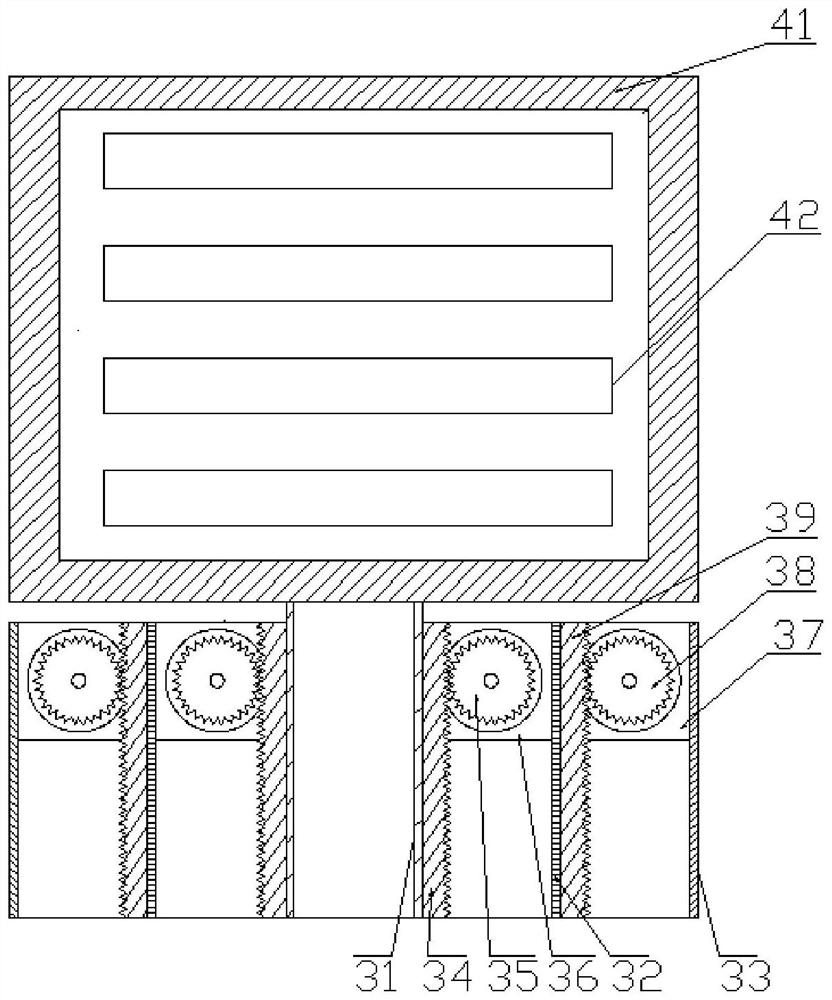

[0016] The lifting platform 3 is composed of an inner cylinder 31, a middle cylinder 32 and an outer cylinder 33. The inner cylinder 31, the middle cylinder 32 and the outer cylinder 33 are all rectangular cylinders. The inner cylinder 31 is arranged in the middle cylinder 32, and the middle cylinder 32 is arranged in the outer cylinder 33. Inside; the inner wall of the middle cylinder 32 is fixedly connected with two symmetrically arranged first stepper motors 36, the power output shaft of the first stepper motor 36 is provided with a first gear 35, and the outer wall of the inner cylinder 31 is provided with two symmetrical The vertical first rack 34, the first gear 35 meshes with the first rack 34, the inner wall of the outer cylinder 33 is fixedly co...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the two end faces of the first gear 35 and the two end faces of the second gear 38 are respectively provided with positioning baffles 30, and the positioning baffles 30 is circular, and the outer diameter of the positioning baffle 30 is greater than the outer diameters of the first gear 35 and the second gear 38 .

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the plurality of infrared heating tubes 42 are arranged in a vertical array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com