Preparation method of polycrystalline diamond wire-drawing die and synthetic block of polycrystalline diamond wire-drawing die

A technology of polycrystalline diamond and wire drawing dies, which is applied to wire drawing dies and other directions, can solve the problems of uneven sintering, affect product quality, and uneven mixing, so as to reduce post-processing costs, reduce laser cutting processes, and improve heating uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

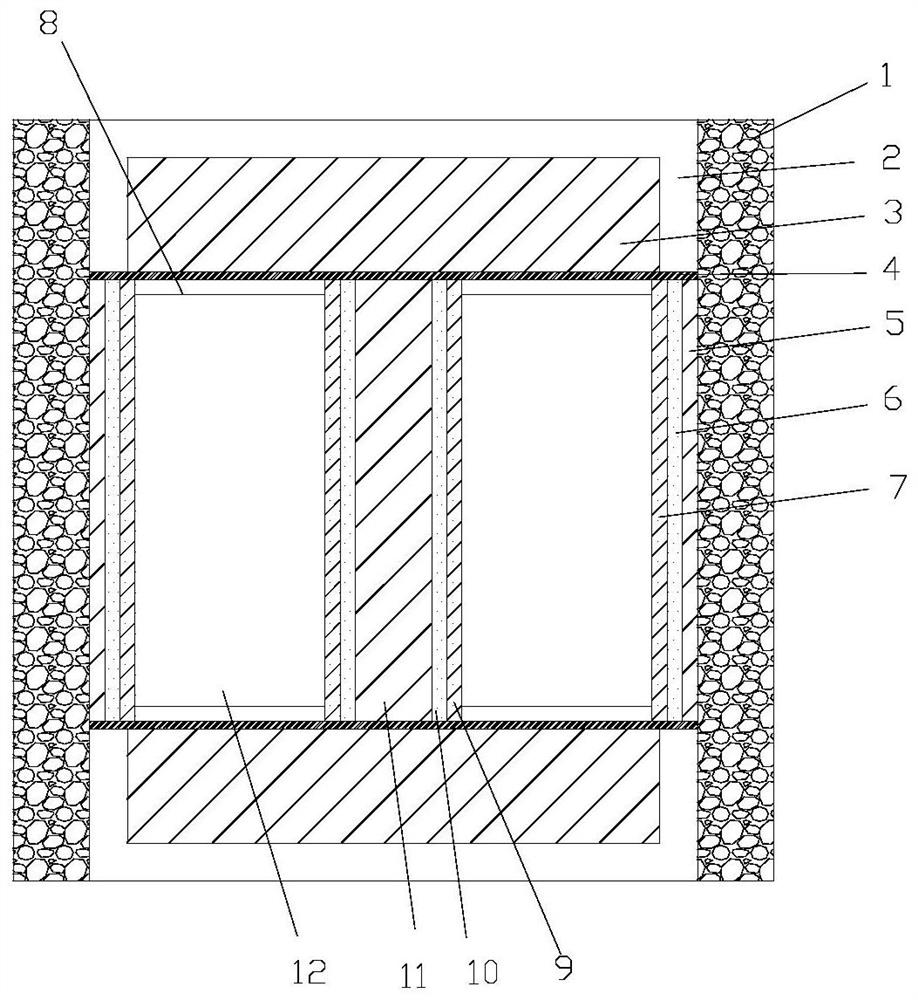

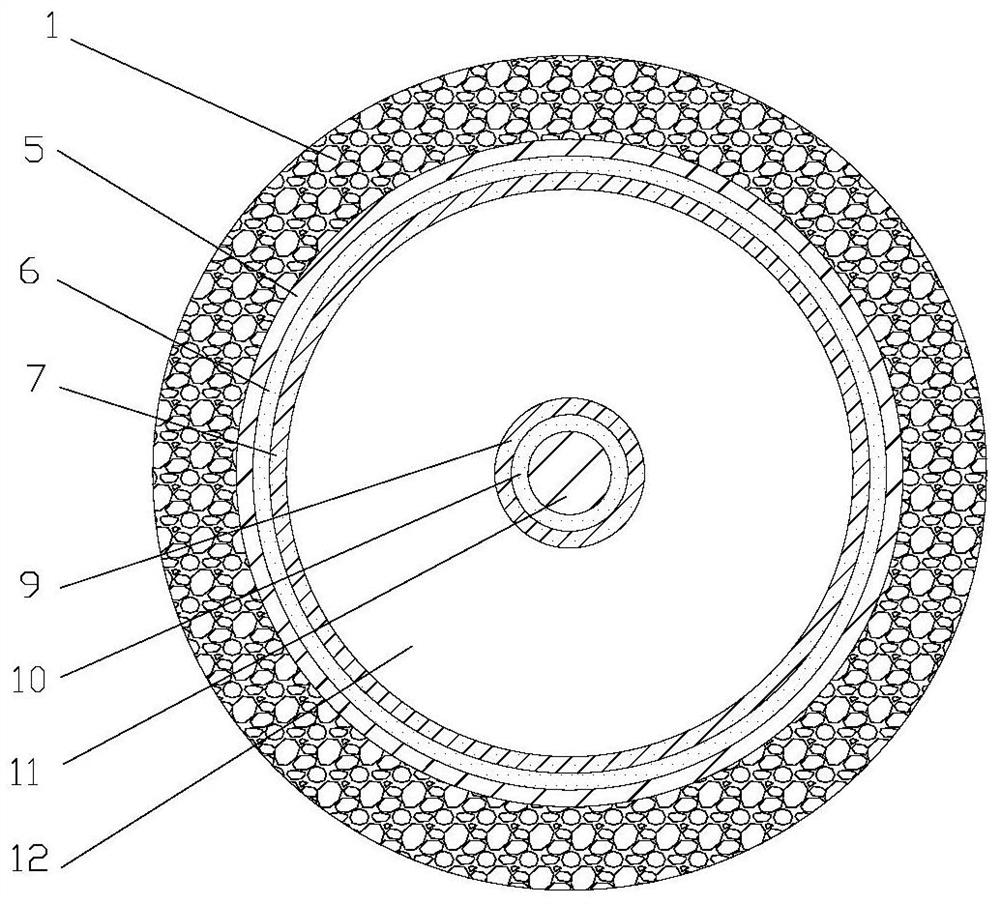

[0034] see Figure 1-6 , the present invention provides the following technical solutions: a method for preparing a polycrystalline diamond wire drawing die, comprising the steps of:

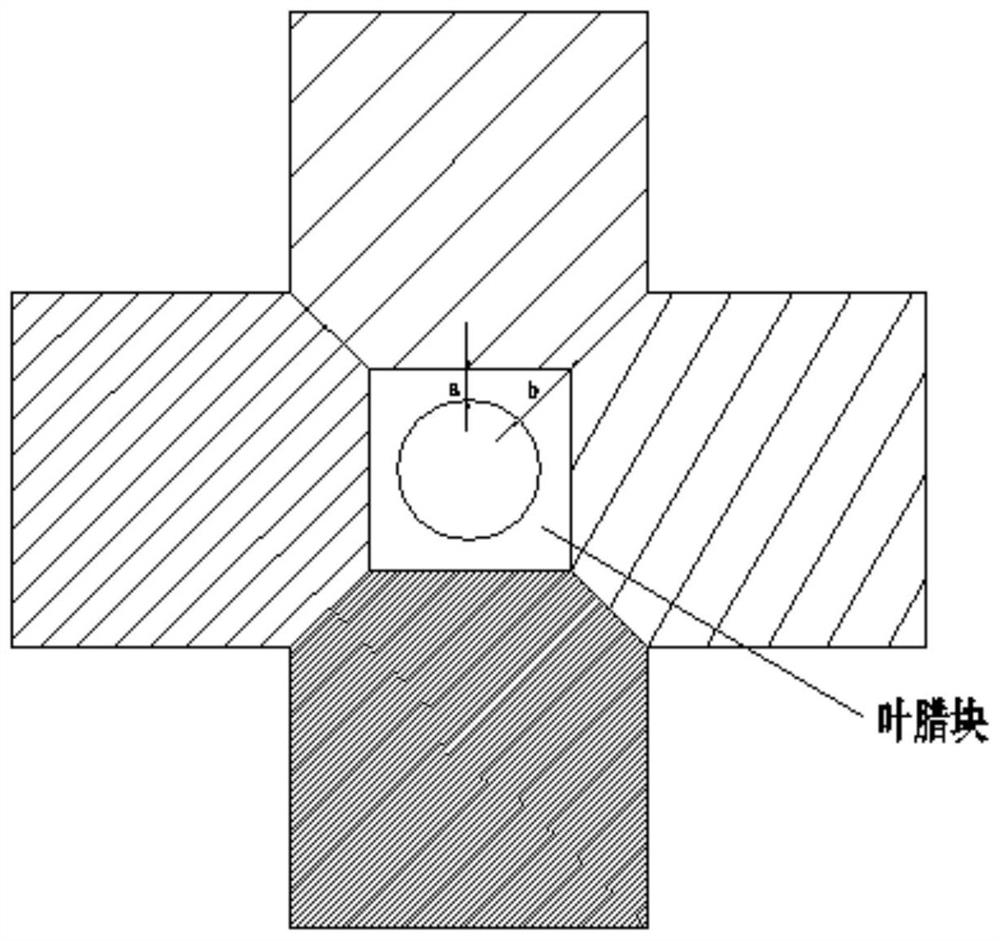

[0035] S1: Prepare a wire drawing die blank. An inner hole is preset in the middle of the wire drawing die blank, and a ring-shaped inner assembly block with an inner hole is pre-pressed for use;

[0036] S2: Assembling the synthetic block, placing the internal assembly block into the pyrophyllite assembly block to make a synthetic block;

[0037] S3: sintering of synthetic blocks; sintering of synthetic blocks in a six-sided top press;

[0038]Wherein: in S2, the synthesis block includes a pyrophyllite block 1 and a ring-shaped inner assembly block encapsulated inside the pyrophyllite block 1, and the center of the inner assembly block is sequentially set with a dolomite column 11 and an inner heating tube. 10. Inner salt pipe 9, the outer circle of the inner assembly block is coaxially provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com