Processing method of glass rod

A processing method and technology of glass rods, which are applied in metal processing equipment, manufacturing tools, grinding tools, etc., can solve problems such as increased processing difficulty, cylindrical surface roughness not meeting the requirements, and large gaps in requirements, etc., to achieve effectiveness and The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

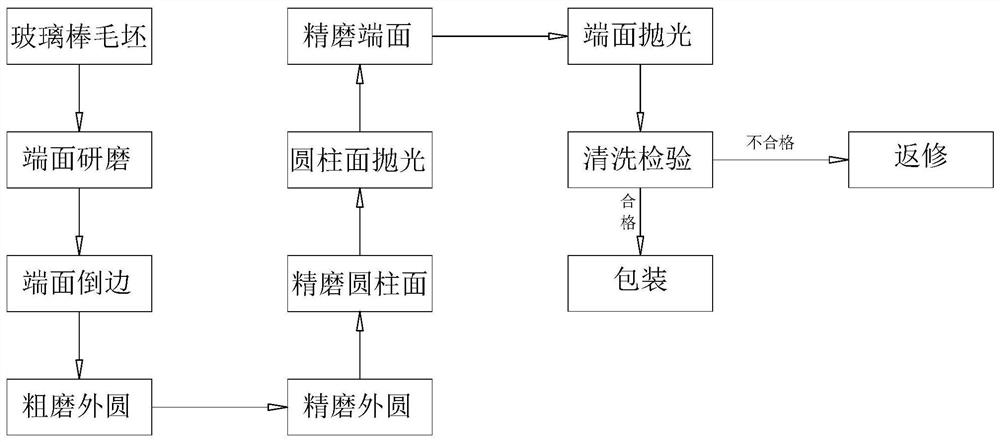

Image

Examples

Embodiment 1

[0056] Processing a certain grade of H-ZFXX optical glass rod, the performance of this glass rod is a product with less hardness and softer texture among optical glass materials. The specification of the glass rod blank before processing is 655mm×Φ42mm. The processing process is as follows:

[0057] End face grinding: clamp the glass rod blank produced by smelting on the end face grinder, and grind the two end faces of the glass rod blank so that the two end faces of the glass rod blank are perpendicular to its cylindrical surface; the grinding wheel used in the end face grinder It is a diamond flat grinding wheel with a diamond concentration of 100%, a particle size of 80#, and a diameter of Φ250mm;

[0058]End beveling: clamp the end-ground glass rod blank on the beveling machine, and grind and bevel the two end faces of the glass rod blank, so that the end face after beveling is compatible with the clamping tool of the cylindrical grinder; The beveling tool used by the beve...

Embodiment 2

[0068] Processing a brand of H-FX optical glass rod, the performance of the glass rod is relatively hard and hard in the optical glass material, the specification of the glass rod before processing is 1000mm×Φ34mm, the processing process is as follows:

[0069] End face grinding: clamp the glass rod blank produced by smelting on the end face grinder, and grind the two end faces of the glass rod blank so that the two end faces of the glass rod blank are perpendicular to its cylindrical surface; the grinding wheel used in the end face grinder It is a diamond flat grinding wheel with a diamond concentration of 100%, a particle size of 60#, and a diameter of Φ250mm;

[0070] End beveling: clamp the end-ground glass rod blank on the beveling machine, and grind and bevel the two end faces of the glass rod blank, so that the end face after beveling is compatible with the clamping tool of the cylindrical grinder; The beveling tool used by the beveling machine is a bowl-shaped tooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com