Domestic sewage treatment station tail water upgrading process system

A technology for sewage treatment station and domestic sewage, applied in biological water/sewage treatment, water/sludge/sewage treatment, polluted waterway/lake/pond/river treatment, etc. Difficult to realize and other problems, to achieve the effect of less land occupation, low construction cost, simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

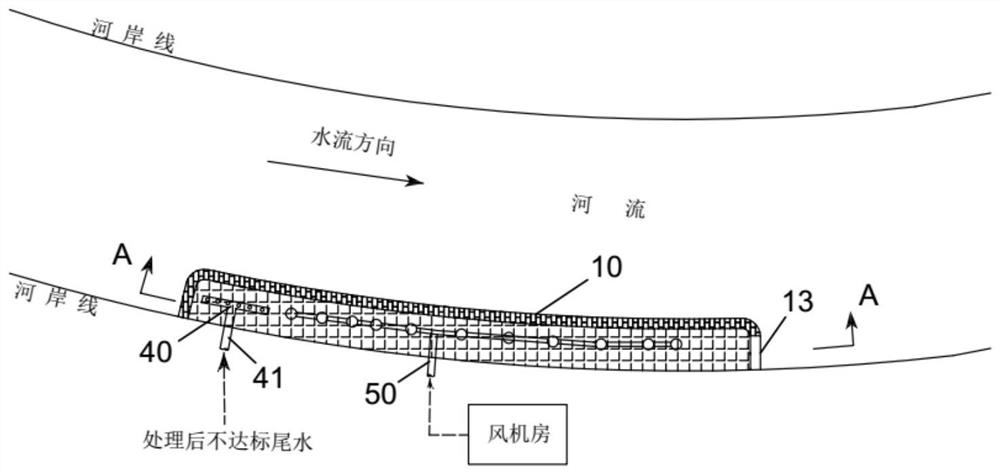

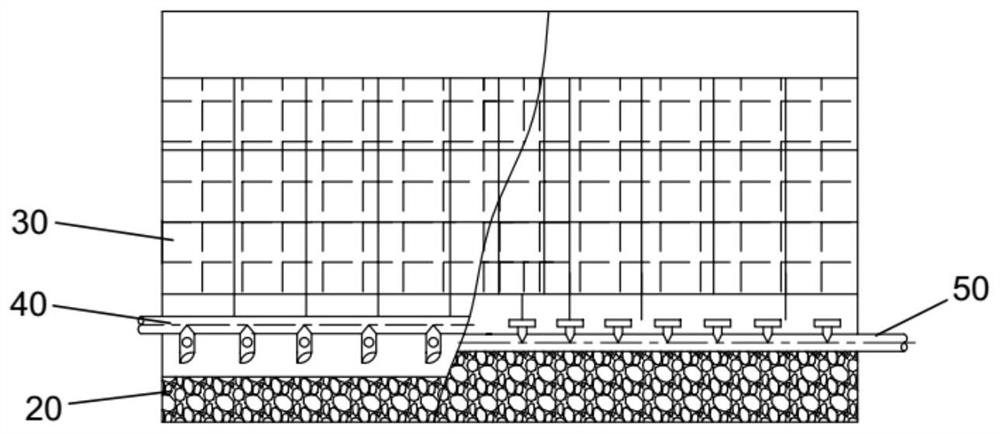

[0023] combine figure 1 , figure 2 , a domestic sewage treatment station tail water upgrading process system, including a corridor ditch 10 surrounded by a number of molding modules, a bio-ceramic layer 20 filled or installed in the corridor ditch, a bio-filler layer 30, bio-ceramic A water distribution system device 40 is provided between the granular layer and the biological filler layer, and the water distribution system device is connected to the tail water outlet of the sewage treatment station.

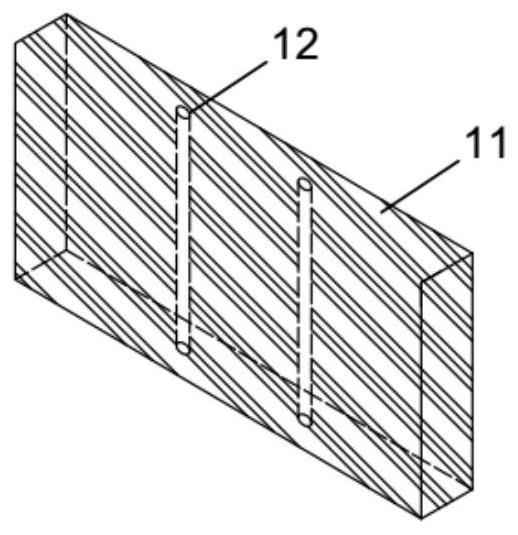

[0024] The corridor ditch 10 is surrounded by a number of forming modules 11. The forming module is a microporous structure and is a customized forming module. The size of a single forming module is 2000mm×500mm×250mm. The forming modules are fixed by fasteners. The forming modules are in production Reinforcing ribs have been implanted according to the design strength, such as image 3 , the forming module is provided with a steel pipe socket 12, and the forming module is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com