Rare earth metal production waste liquid treatment method and device thereof

A technology of waste liquid treatment and rare earth metals, which is applied in the direction of metallurgical wastewater treatment, filtration treatment, chemical instruments and methods, etc., can solve the problems of oil leakage, poor oil adsorption capacity, and occupied oil storage capacity, etc., to improve sealing ability and improve Effect of adsorption capacity and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

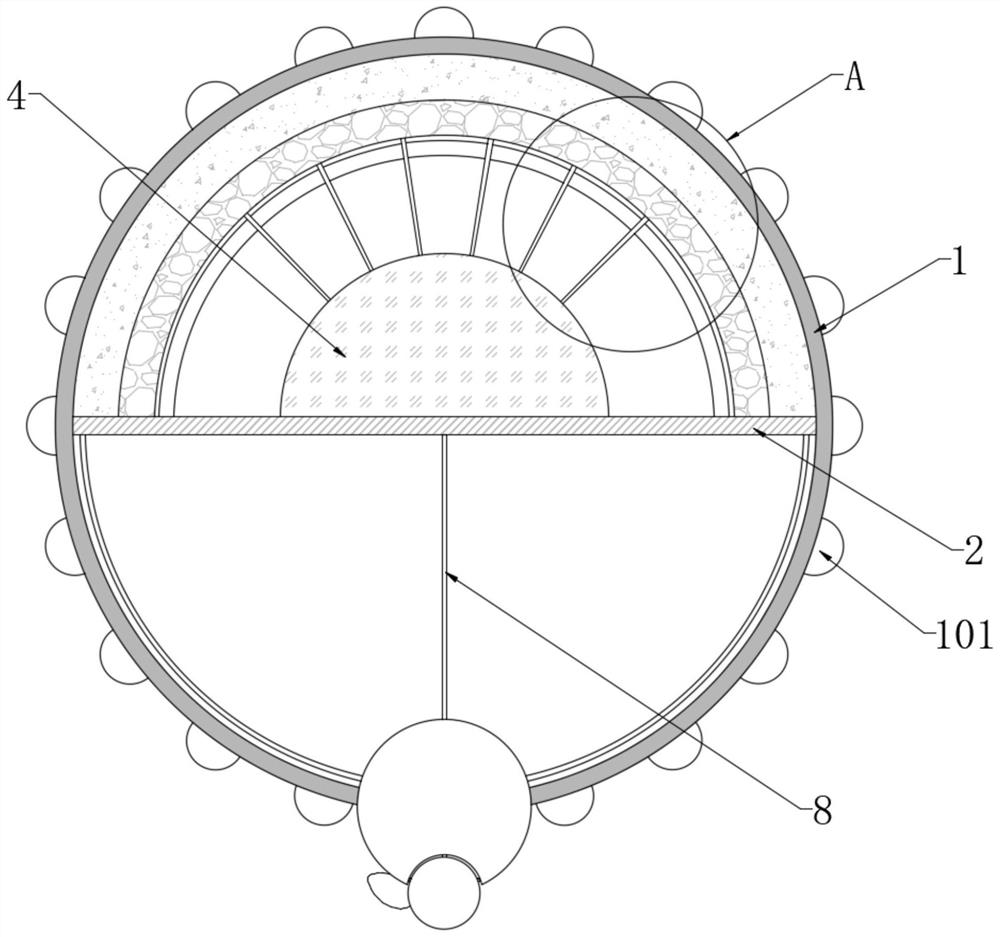

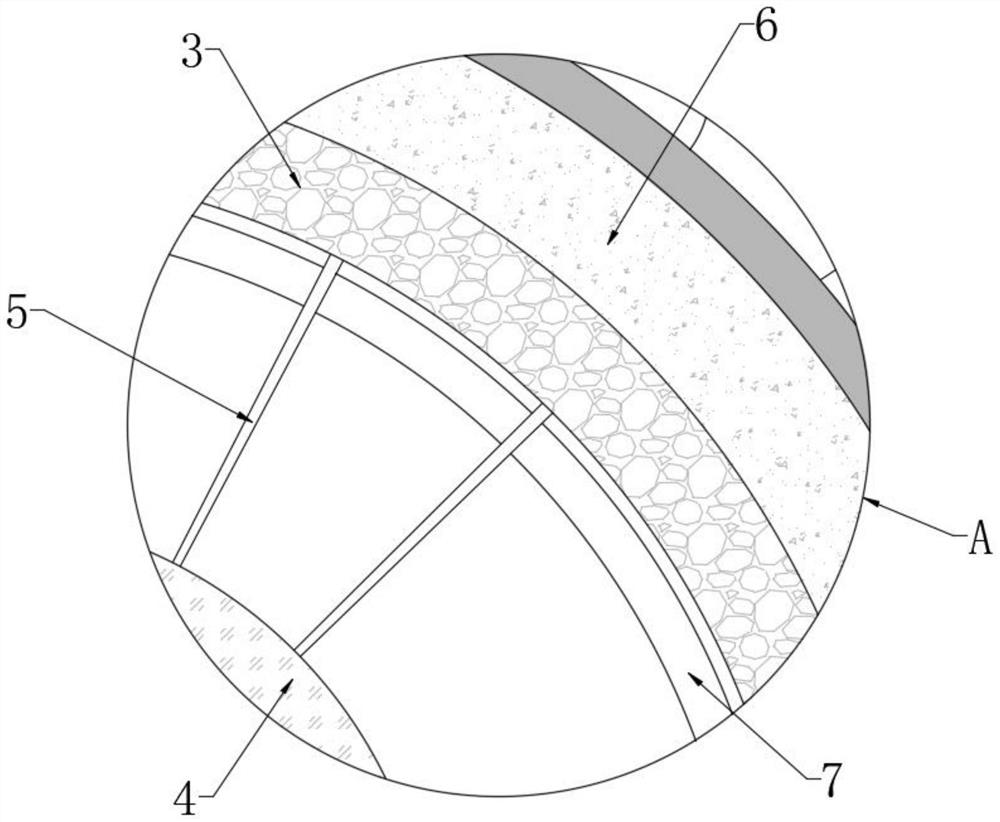

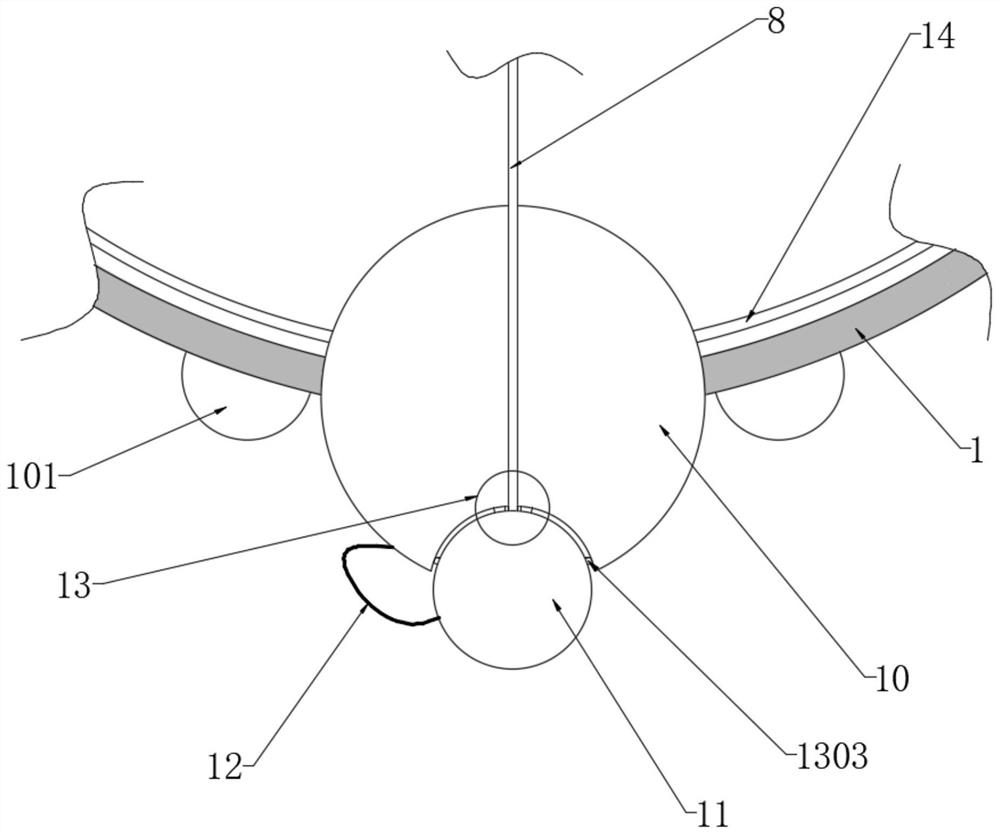

[0047] see Figure 1-5 , a rare earth metal production waste liquid treatment device, comprising an adsorption shell 1, the inner wall of the adsorption shell 1 is fixedly connected with a trigger partition 2, the upper side wall of the trigger partition 2 is fixedly connected with an adsorption cotton 3, and the center of the upper side wall of the trigger partition 2 is The oil storage hemisphere 4 is fixedly connected to the oil storage hemisphere 4, and a plurality of cotton threads 5 are connected between the adsorption cotton 3 and the oil storage hemisphere 4. The filter sand 6 is filled between the adsorption cotton 3 and the filter sand 6, and the filter sand 6 adopts oil-permeable and water-repellent Made of sand, it has strong water blocking ability, improves the adsorption effect of oil pollution, avoids the rapid saturation of storage capacity due to the inhalation of a large amount of waste liquid, and significantly improves the adsorption capacity of oil pollutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com