Ecological transfer printing fabric processing technology

A technology for processing technology and fabrics, applied in printing technology, transfer printing method, printing and other directions, can solve the problems of inability to fully realize transfer printing, affecting the integrity and quality of transfer printing type, affecting the effect of surface treatment of fabrics, etc. Improve quality stability, improve adhesion uniformity, and the effect of fine pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment discloses a process for processing ecological transfer printed fabrics, including the following steps:

[0031] S1 Transfer film preparation, plate making according to the designed pattern, processing to form a gravure roller mold; when preparing the transfer film, use high temperature resistant PET film as the base material, first coat the transfer printing medium on the surface of the film; and then pass the gravure The printing machine prints the required pattern on the film, forms a pattern pattern on the film, and forms a transfer film;

[0032] S2 fabric pre-treatment, before the fabric is transferred, the fabric is pre-treated and soaked with the pre-treatment liquid, so that the surface of the fabric has good activity and can dissolve and transfer the ink on the transfer film; the fabric is immersed in the treatment pool , use 10-30 ℃ normal temperature environment for soaking, when the temperature is too high or too low, the temperature needs to...

Embodiment 2

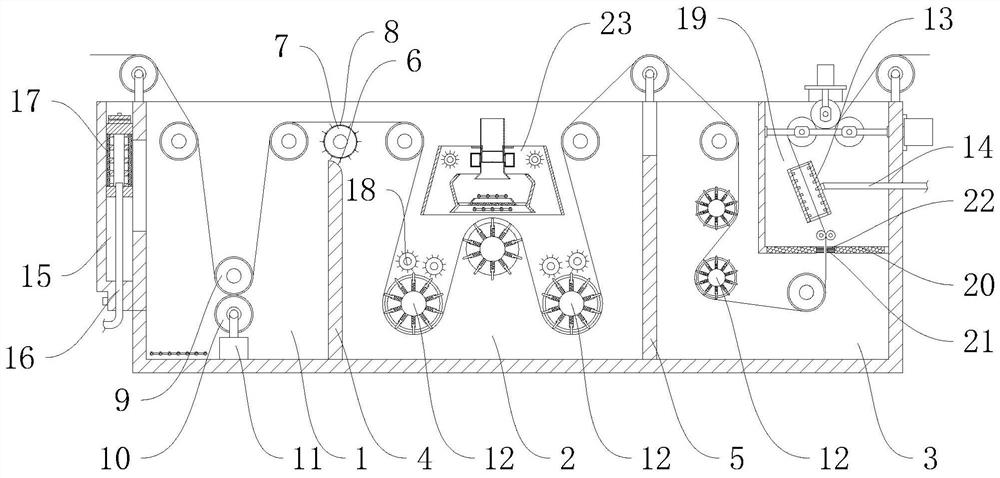

[0039] This embodiment discloses a kind of ecological transfer printing fabric processing technology, on the basis of embodiment one, and refer to figure 1 Further explanation; the fabric pretreatment system in the S2 fabric pretreatment includes a treatment pool, the treatment pool is the main body, and the treatment liquid is poured into the treatment pool. When processing, the fabric is passed through the treatment pool. The treatment liquid in the treatment pool is The surface of the fabric is impregnated.

[0040] The inside of the treatment pool is divided into treatment tank one 1, treatment tank two 2 and treatment tank three 3 by partition one 4 and partition two 5, and the three treatment tanks are arranged in sequence, and treatment tank two 2 is located between treatment tank one 1 and treatment tank Between the three 3, an arc-shaped water retaining surface 6 gradually rising toward the treatment tank one 1 is formed at the upper end of the dividing plate one 4, a...

Embodiment 3

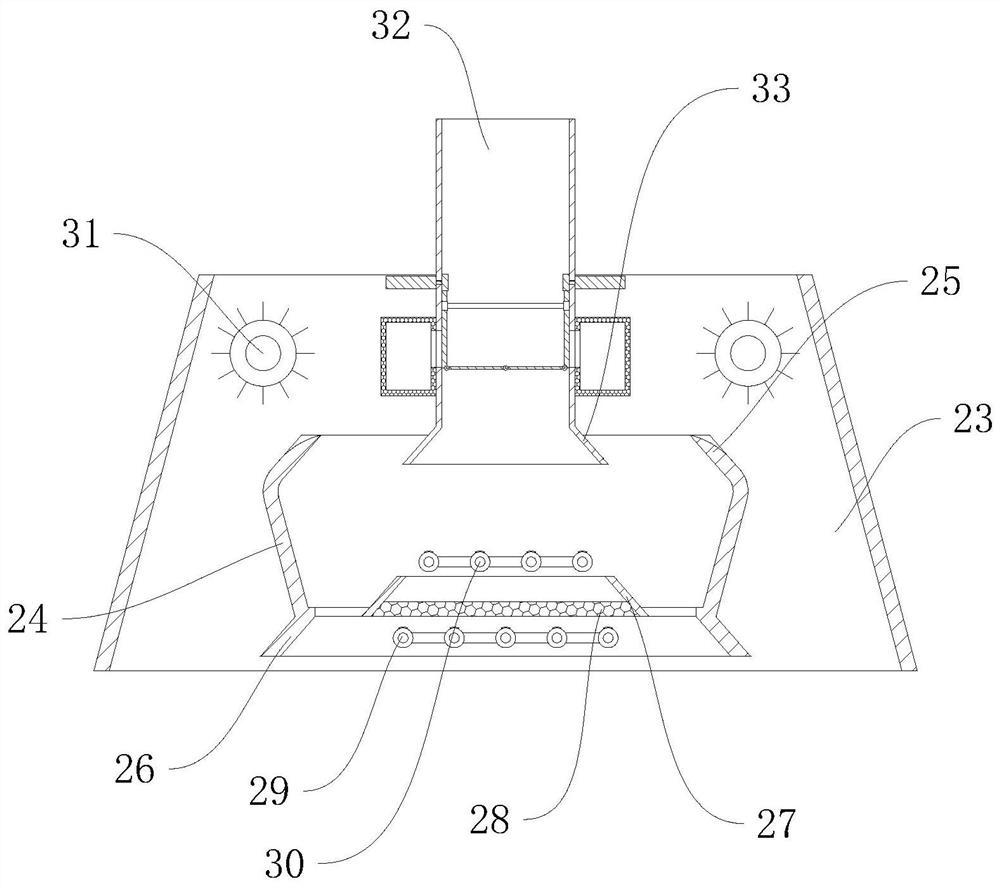

[0048] This embodiment discloses a kind of ecological transfer printing fabric processing technology, on the basis of embodiment two, and refer to figure 1 and Figure 5 , 6 Explain in detail and further optimize the combing and water control in the pre-treatment process of S2 fabrics;

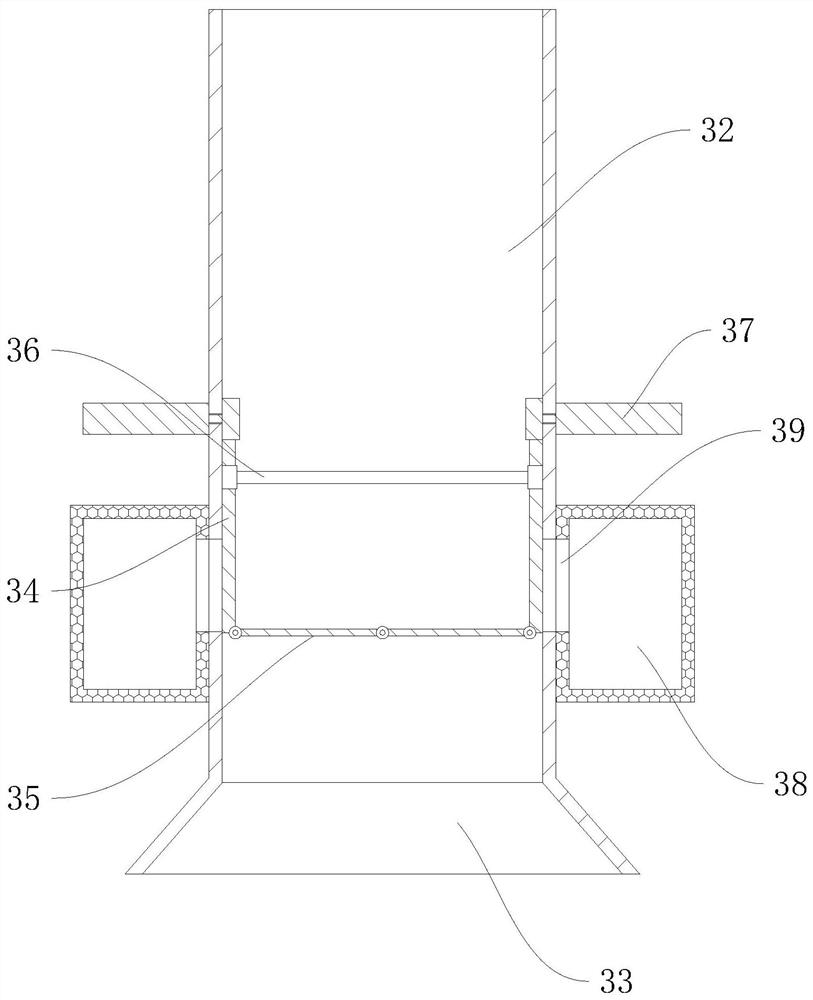

[0049] A water control device is set in the liquid inlet tank 19, and the water control device can squeeze and control the water of the passing fabric. The water control device specifically includes two water control rollers one 54 and one water control roller two 55. Screw rod 51 is installed in the middle of 19, screw rod 51 is threadedly connected with two sliding seats 53, and on the sliding seat 53, all rotations are connected with water control roller 1 54, and two sliding seats 53 are opposite to the screw thread direction between screw rod 51 respectively, make During the rotation of screw rod 51, the water control roller one 54 can form relative or move away from each other; Weekly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com