Fabricated leveling composite radiation energy-saving orthogonal laminated wood wall and construction method thereof

A composite radiation and prefabricated technology, applied in passive houses, buildings, climate sustainability, etc., can solve the problems of inability to modularize the construction of light steel keels, increase in manpower and working hours, and reduce the thermal insulation effect, so as to reduce the construction workload. , The effect of building fast, reducing thickness and self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

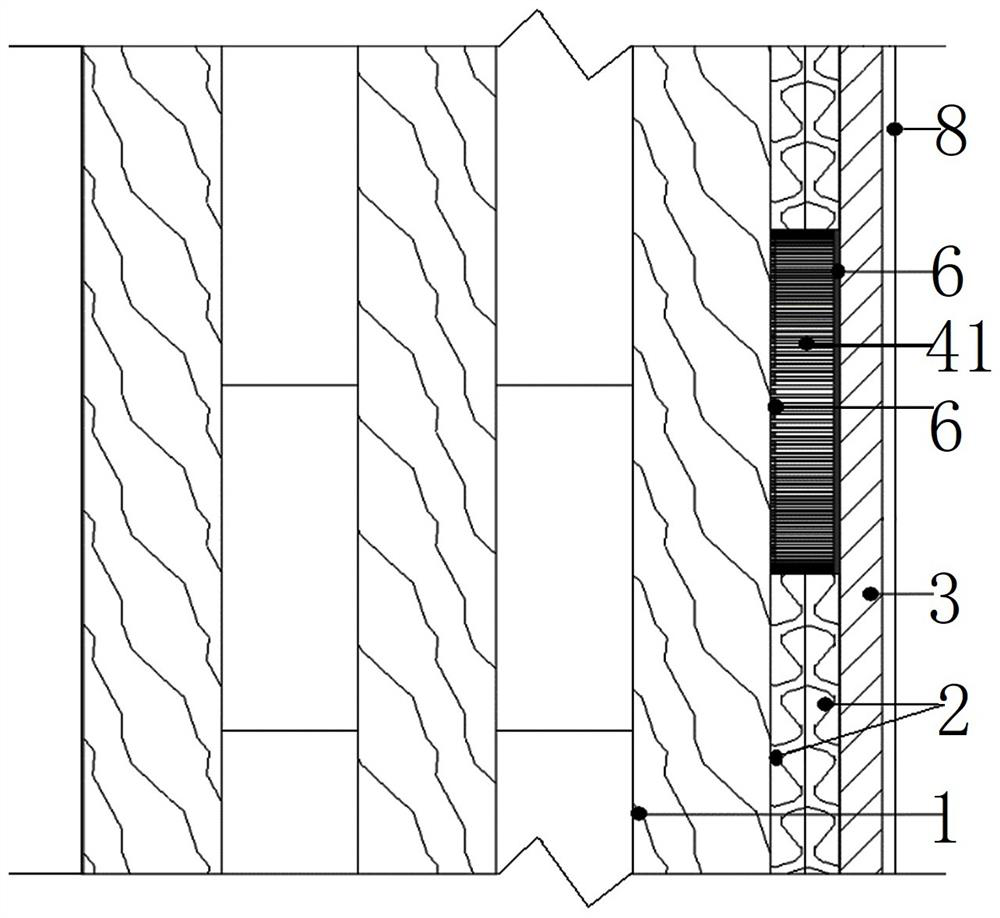

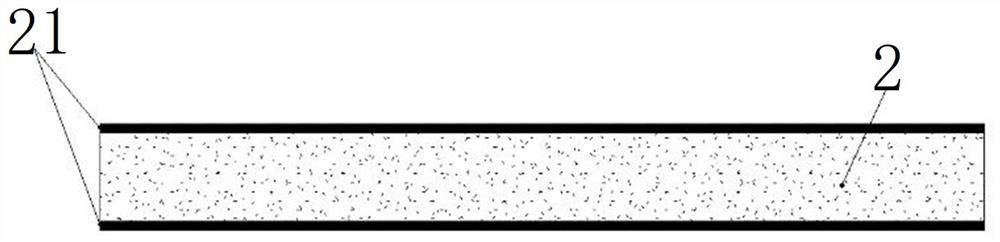

[0048] Such as figure 1 As shown, the prefabricated leveling composite radiant energy-saving cross-glued wood wall includes cross-glued wood wall 1; the surface of one side or both sides of cross-glued wood wall 1 is wrapped with insulation coil 2; figure 2 As shown, the two sides of the thermal insulation coil 2 are respectively wrapped with metal foils 21 for constraining and protecting fragile thermal insulation materials; in this embodiment, the metal foil 21 is made of aluminum foil. Heat radiation also plays a protective role, so its thickness should be thicker without affecting the bending of the insulation coil 2 .

[0049] The insulation coiled material 2 is a hydrophobic material to prevent it from being wetted or water infiltrated, so as to play a waterproof effect. In this embodiment, the thermal insulation coil 2 is an inorganic airgel felt such as silica airgel felt. This material has fine fluff on the surface, and is not sticky to water like a lotus leaf, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com