Water supply and condensation water cooperative system of direct air cooling unit based on double-fed system

An air-cooled unit and collaborative system technology, applied in steam/steam condensers, mechanical equipment, steam engine installations, etc., can solve the problem of difficult to meet the safety and economic requirements of direct air-cooled units, harsh operating environment requirements, and heavy operation and maintenance workload. and other problems, to achieve the effect of small footprint, high reliability and high adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred implementation examples of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

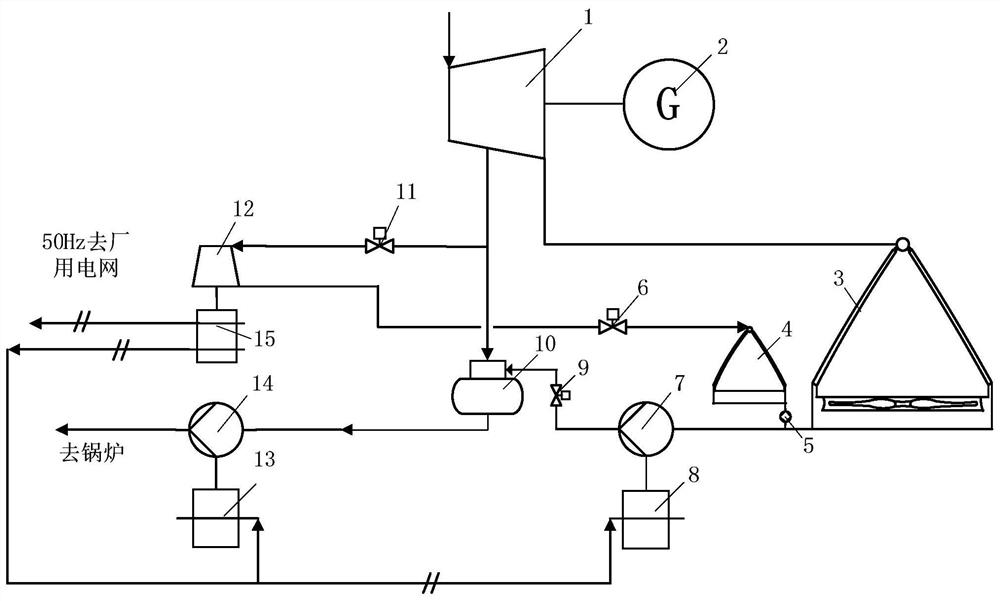

[0026] like figure 1 As shown, a direct air-cooled unit feedwater and condensate synergy system based on a double-fed system provided by the present invention includes a steam turbine 1, a generator 2, an air-cooled island 3, a surface cooler 4, a small condensate pump 5, and a condensate pump 7 , condensate pump motor 8, deaerator 10, cooperative drive steam turbine 12, feed pump motor 13, feed water pump 14 and dual-frequency double-fed generator 15; steam turbine 1 and generator 2 are coaxially connected, condensate pump motor 8 and condensate water pump 7 Coaxial connection, the feed pump motor 13 and the feed water pump 14 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com