Three-proofing paint coating quality detection system and method

A quality inspection method and detection system technology, applied in the field of conformal paint coating quality inspection system, can solve the problems of unclear threshold standards, health hazards of inspectors, and low efficiency, so as to reduce the amount of computation, improve detection accuracy, and improve efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

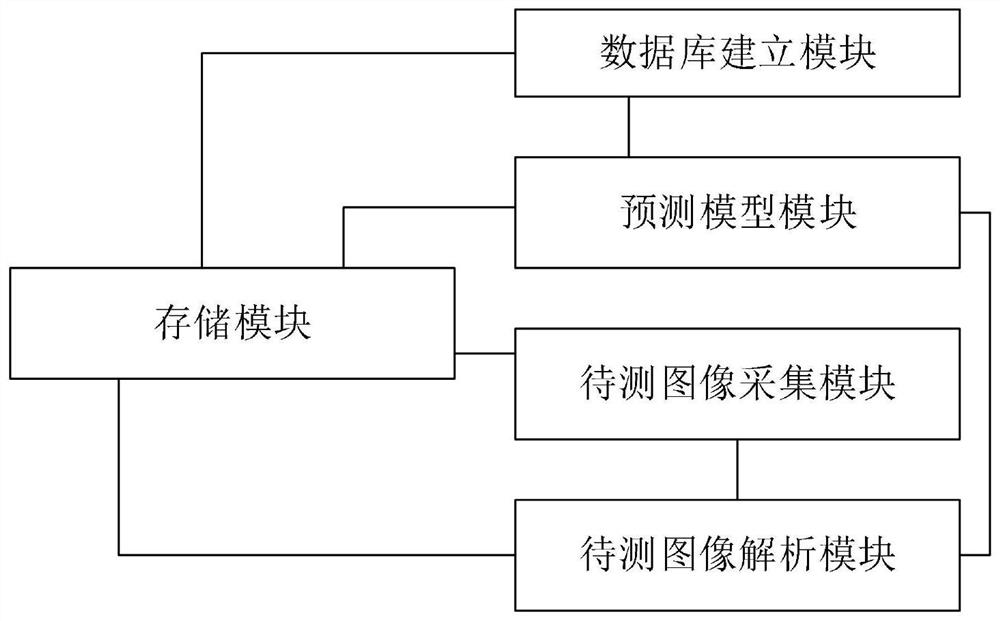

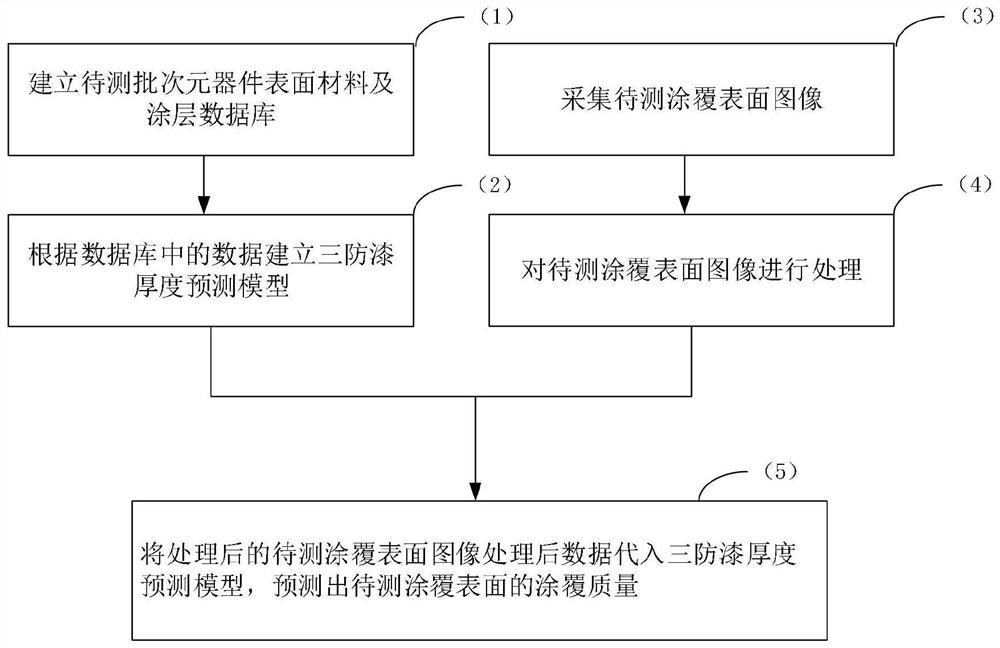

[0033] Specific implementation mode 1 such as figure 1 As shown, a conformal paint coating quality inspection system includes a storage module, a database establishment module, a prediction model module, an image acquisition module to be tested, and an image analysis module to be tested;

[0034] The storage module is used to store the data generated in the quality inspection process of the conformal paint coating; the database establishment module is used to establish the surface material and coating database of the batch of components to be tested; the prediction model module is used to base on the data in the database Establish a three-proof paint thickness prediction model, and substitute the processed image processing data of the coating surface to be tested into the three-proof paint thickness prediction model to predict the coating quality of the coating surface to be tested; the image acquisition module to be tested is used for The image of the coated surface to be tes...

specific Embodiment approach 2

[0036] Specific implementation mode 2 such as figure 1 As shown, a conformal paint coating quality inspection system includes a storage module, a database establishment module, a prediction model module, an image acquisition module to be tested, and an image analysis module to be tested;

[0037] The storage module is used to store the data generated in the quality inspection process of the conformal paint coating; the database establishment module is used to establish the surface material and coating database of the batch of components to be tested; the prediction model module is used to base on the data in the database Establish a three-proof paint thickness prediction model, and substitute the processed image processing data of the coating surface to be tested into the three-proof paint thickness prediction model to predict the coating quality of the coating surface to be tested; the image acquisition module to be tested is used for The image of the coated surface to be tes...

specific Embodiment approach 3

[0040] Specific embodiment 3 such as figure 1As shown, a conformal paint coating quality inspection system includes a storage module, a database establishment module, a prediction model module, an image acquisition module to be tested, and an image analysis module to be tested;

[0041] The storage module is used to store the data generated in the quality inspection process of the conformal paint coating; the database establishment module is used to establish the surface material and coating database of the batch of components to be tested; the prediction model module is used to base on the data in the database Establish a three-proof paint thickness prediction model, and substitute the processed image processing data of the coating surface to be tested into the three-proof paint thickness prediction model to predict the coating quality of the coating surface to be tested; the image acquisition module to be tested is used for The image of the coated surface to be tested is col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com