Rapid activation method for fuel cell

An activation method and fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of slow temperature response, slow temperature drop of the stack, water flooding, etc., and achieve the effect of rapid activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

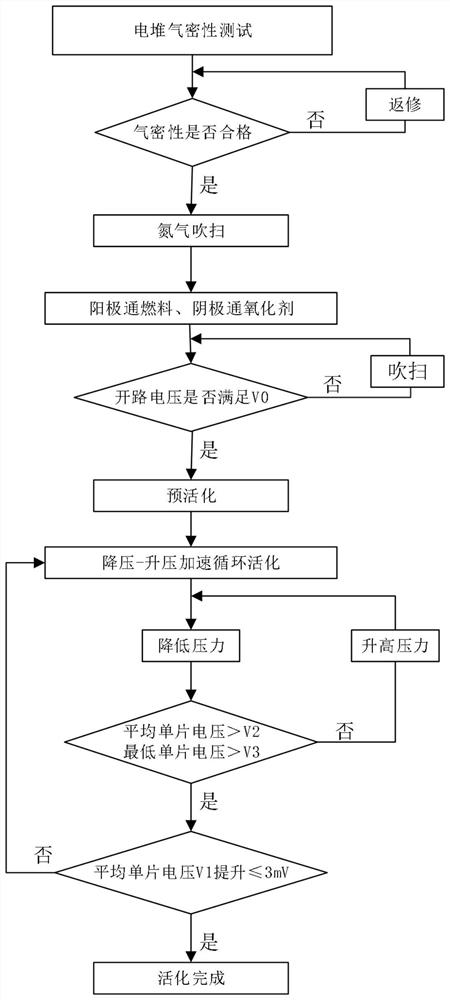

[0025] refer to figure 1 , an embodiment of the present invention provides a rapid activation method for a fuel cell, comprising the following steps:

[0026] S1. Stack airtightness test: check whether the airtightness of the fuel cell stack meets the airtightness index; if yes, proceed to the next step; if not, perform stack repair;

[0027] S2. Nitrogen purge: feed nitrogen into the anode and cathode of the stack to be activated to purge the stack; the stack purge time is 1 min;

[0028] S3. Feed reaction gas: After the ventilation and purging is completed, switch the reaction gas source, feed humidified hydrogen into the anode, and feed humidified oxygen into the cathode, so that the stack is in an open circuit state until the average single-cell open circuit voltage reaches 0.95V. 5min;

[0029] S4. Pre-activation: Turn on the load, select the constant current loading mode, gradually increase the current, and gradually increase the inlet pressure of the anode and cathode...

Embodiment 2

[0033] S1. Stack airtightness test: check whether the airtightness of the fuel cell stack meets the airtightness index; if yes, proceed to the next step; if not, perform stack repair;

[0034] S2. Nitrogen purge: feed nitrogen into the anode and cathode of the stack to be activated to purge the stack; the stack purge time is 2 minutes;

[0035] S3. Introduce reaction gas: After the ventilation and purging is completed, switch the reaction gas source, pass in humidified hydrogen to the anode, and pass in humidified oxygen to the cathode, so that the stack is in an open circuit state until the average single-cell open circuit voltage reaches 0.96V, and maintain 4min;

[0036] S4. Pre-activation: turn on the load, select the constant current loading mode, gradually increase the current, and gradually increase the inlet pressure of the anode and cathode until the activation voltage is V1, the V1 is 0.62V, the cathode inlet pressure is 90kPa, and the anode remains higher than The ...

Embodiment 3

[0040] S1. Stack airtightness test: check whether the airtightness of the fuel cell stack meets the airtightness index; if yes, proceed to the next step; if not, perform stack repair;

[0041] S2. Nitrogen purge: feed nitrogen into the anode and cathode of the stack to be activated to purge the stack; the stack purge time is 3 minutes;

[0042] S3. Introduce reaction gas: After the ventilation and purging is completed, switch the source of reaction gas, pass in humidified hydrogen to the anode, and pass in humidified oxygen to the cathode, so that the stack is in an open circuit state until the average single-cell open circuit voltage reaches 0.97V, and maintain 3min;

[0043] S4. Pre-activation: Turn on the load, select the constant current loading mode, gradually increase the current, and gradually increase the inlet pressure of the anode and cathode until the activation voltage is V1, the V1 is 0.65V, the cathode inlet pressure is 100kPa, and the anode remains higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com