Fermented earthworm powder and preparation method thereof

An earthworm powder and earthworm technology, which is applied in the directions of powder transportation, medical raw materials derived from leeches/helminths, antibacterial drugs, etc. Improve and promote the effect of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

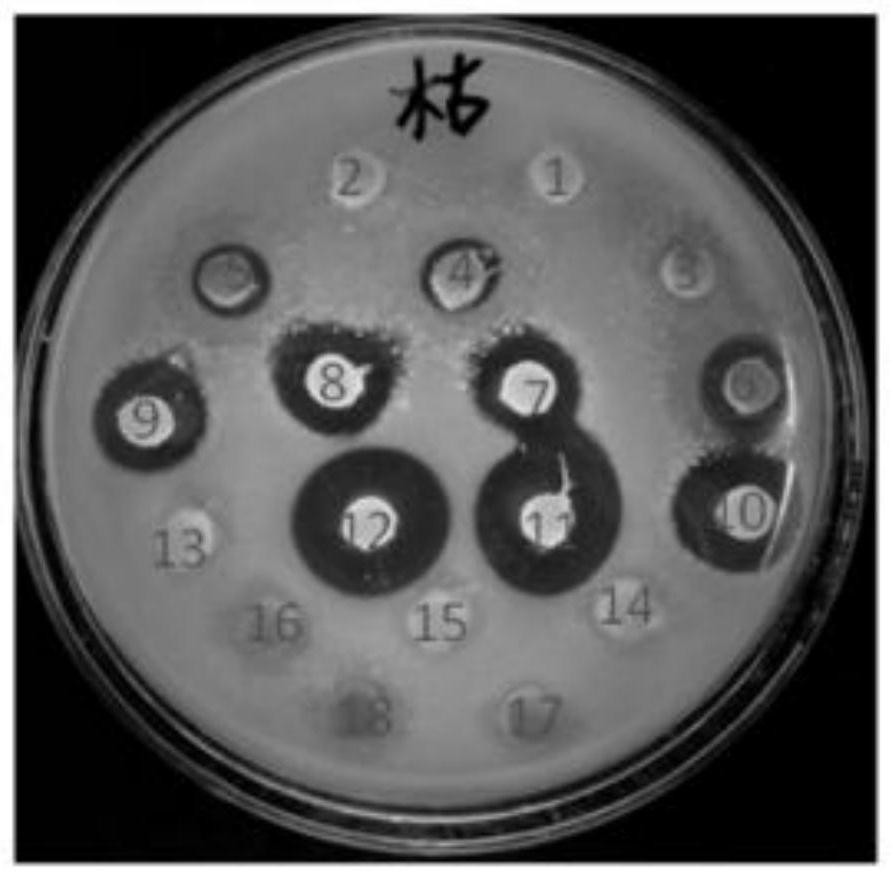

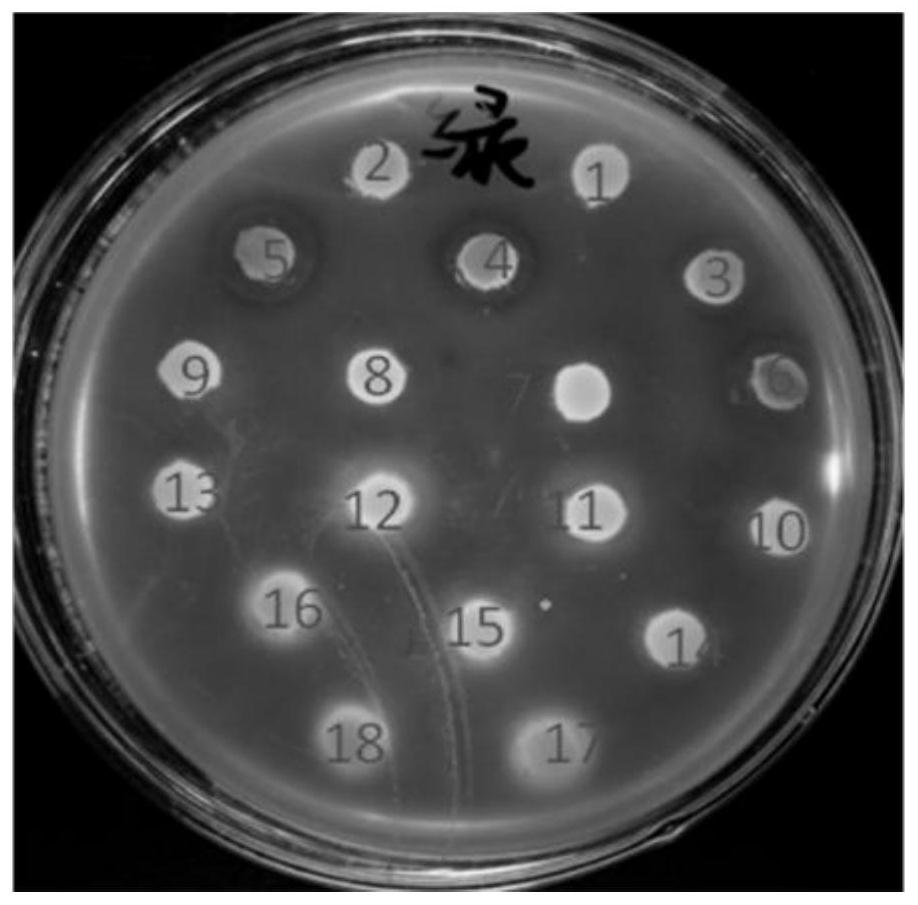

Image

Examples

preparation example Construction

[0028] The embodiment of the present application proposes a kind of preparation method of fermented earthworm meal, comprises the following steps:

[0029] The earthworms are ground for 100-140 minutes, the grinding temperature is gradually increased from 60-62° C. to 78-80° C., water is added during the grinding process, and an earthworm grinding liquid is obtained after the grinding is completed.

[0030] Fermentation is carried out at 78-82°C by adding a mixture to the earthworm grinding liquid, the mixture includes Staphylococcus carnosus with a mass percentage of 66-70% and neutral protease with a mass percentage of 30-34%, and the earthworms are obtained after fermentation and enzymolysis fermentation broth.

[0031] Phosphate is added to the earthworm fermentation liquid to adjust the pH value to 4.5-6.5, so as to maintain the stability of the earthworm fermentation liquid.

[0032] The earthworm fermented liquor added with phosphate is dried to make powder, and the fe...

Embodiment 1

[0063] 1. Select live earthworms and clean them.

[0064] 2. Grinding and physical crushing: the grinding temperature is 60-78°C, it takes 55 minutes to rise from 60°C to 78°C, and it takes 55 minutes to grind at 80°C for 85 minutes, and the total grinding time is 140 minutes. Add water during grinding, and the amount of water added is fresh 2.5 times the amount of earthworms.

[0065] 3. Fermentation and decomposition: the earthworm grinding liquid is first fermented, and a mixture of 15% of the filtrate mass is added during the fermentation, and the fermentation time is 7 days, and the fermentation temperature is 80° C.; the mixture includes Staphylococcus carnosus with a mass percentage of 66% and 34% Protease.

[0066] 4. Stable release: After the fermentation is completed, the earthworm fermentation broth is obtained, and dipotassium hydrogen phosphate with an amount of 3% of the mass of the earthworm fermentation liquor is added to the liquid, and the function release a...

Embodiment 2

[0069] 1. Select fresh and live earthworms and clean them;

[0070] 2. Grind the earthworms: the grinding temperature is 62-80°C, it takes 65 minutes to rise from 62°C to 80°C, and the grinding time is set at 82°C for 35 minutes, the total grinding time is 100 minutes, and water is added during the grinding period. 2.5 times the amount of live earthworms;

[0071] 3. Fermentation and decomposition: the earthworm ground liquid is firstly fermented, and a mixture of 18% of the filtrate mass is added during the fermentation, the fermentation time is 7 days, and the fermentation temperature is 78°C; the mixture includes Staphylococcus carnosus with a mass percentage of 68% and 32% Protease.

[0072] 4. Stable release: After the fermentation is completed, earthworm fermentation liquid is obtained, and disodium hydrogen phosphate with an amount of 4% of the mass of the earthworm fermentation liquid is added to the liquid, and the function release and stable activity operation are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com