Device for reducing evaporated condensate and stabilizing urea production and treatment method

A condensate and stable technology, applied in evaporation, separation methods, cascade evaporators, etc., can solve the problem of condensate blocking the lower liquid port and affecting the stable operation of the device, and achieve the improvement of small investment, reasonable structure and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

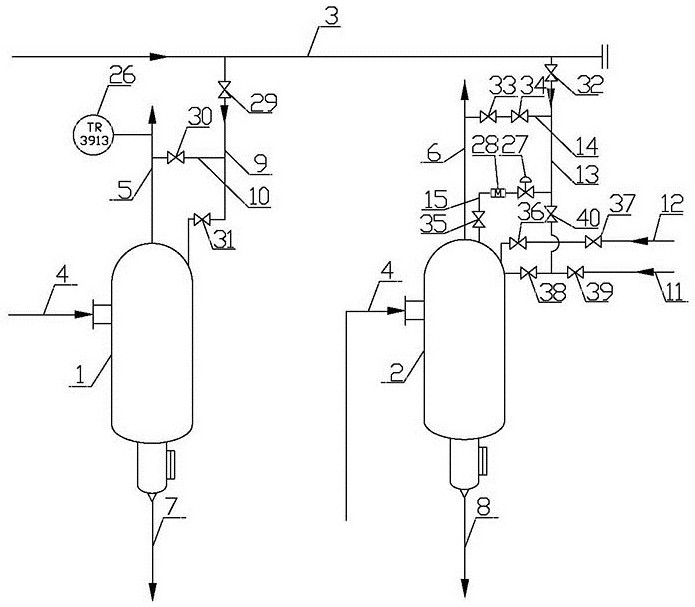

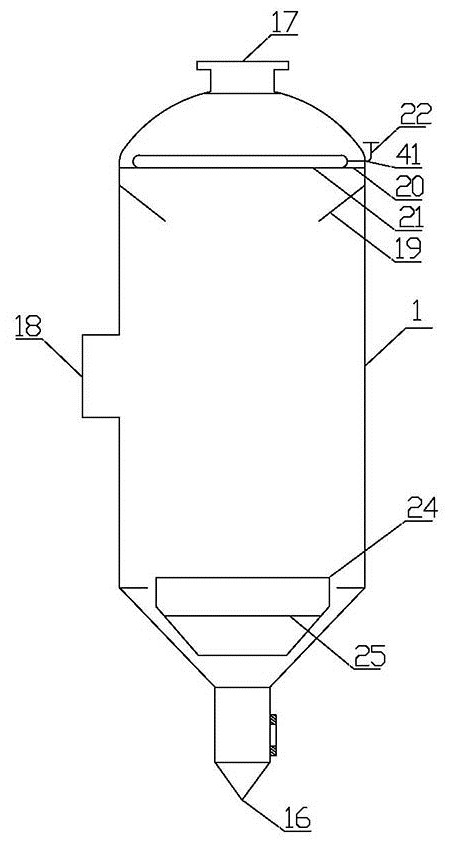

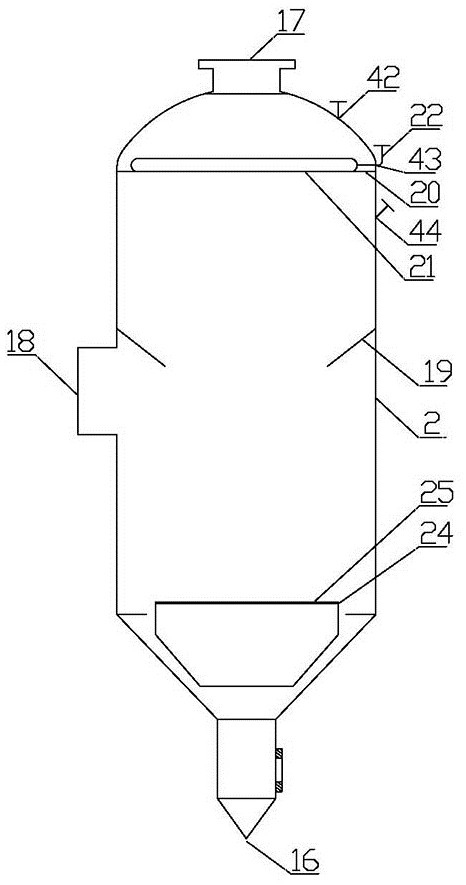

[0023] Embodiment 1: as attached figure 1 As shown, the device for reducing and evaporating condensates to stabilize urea production includes a first-stage evaporative separator 1, a second-stage evaporative separator 2, and a condensate main pipe 3, and the upper inlet of the first-stage evaporative separator 1 and the upper inlet of the second-stage evaporative separator 2 are respectively The urine pipeline 4 is fixedly connected, the top outlet of the first-stage evaporative separator 1 is fixedly connected with a vapor phase pipeline 5, the top outlet of the second-stage evaporative separator 2 is connected with a second vapor phase pipeline 6, and the bottom outlet of the first-stage evaporative separator 1 is fixedly connected with a vapor phase pipeline 5. Evaporation-liquid phase pipeline 7, second-stage evaporation separator 2 bottom outlet is fixedly connected with second evaporation-liquid phase pipeline 8, between the top inlet of first-stage evaporation separator ...

Embodiment 2

[0034] Embodiment 2: as attached figure 1Shown, the treatment method of this device that reduces the evaporating condensate stable urea production is carried out as follows: the urine heated by a steam heater enters the first section of evaporation separator by the feed port 18 on the first section of evaporation separator 1 1, the gas-liquid separation is carried out, the obtained gas phase is exported through a vapor phase pipeline 5, and the obtained liquid phase is sent to the second steam heater by the discharge port 16 after passing through the anti-vortex baffle 24, and the urine heated by the second steam heater is The liquid enters the second-stage evaporation separator 2 from the feed port 18 on the second-stage evaporation separator 2 for gas-liquid separation, the obtained gas phase is output through the second vapor phase pipeline 6, and the obtained liquid phase is output through the second evaporation liquid phase pipeline 6 , when it is necessary to flush the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com