Animal feed preparation process

A technology of animal feed and preparation technology, which is applied in the direction of feed, grain processing, food science, etc. It can solve the problems of hidden safety hazards, dependence on manual cleaning, poor sanitation effect, etc., to save production costs, realize linkage operation, and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

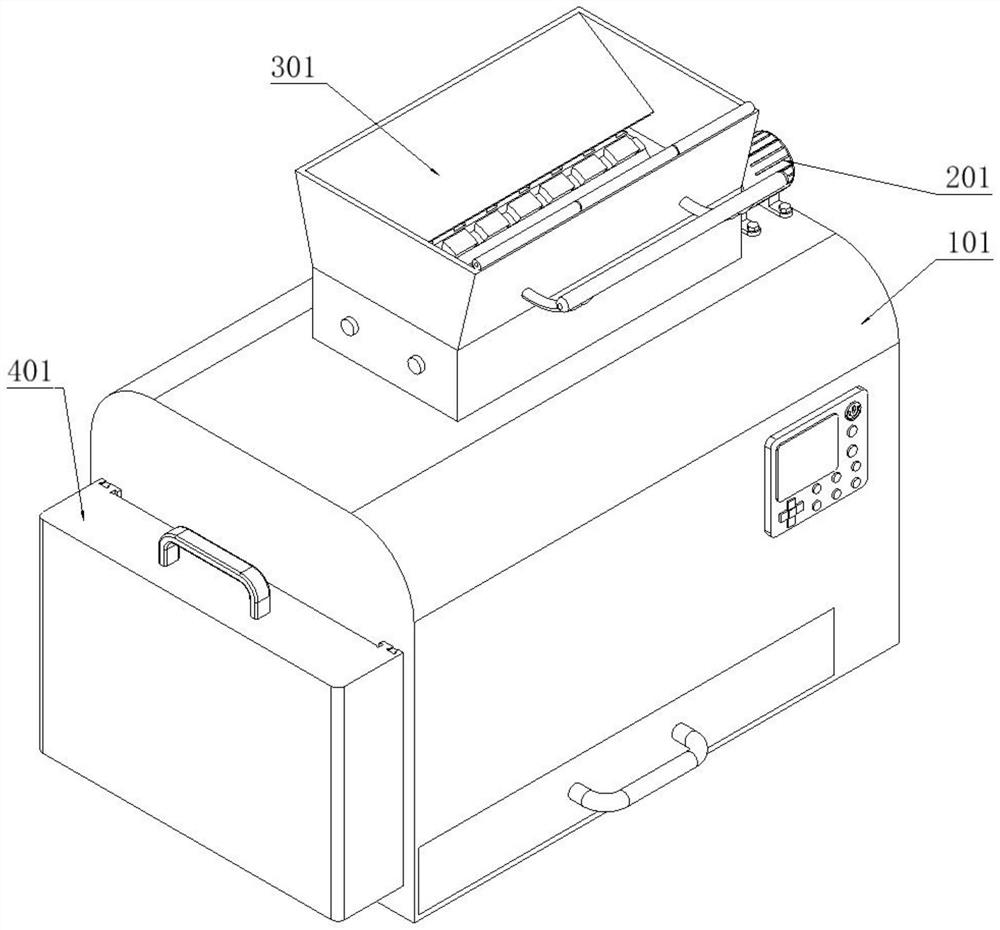

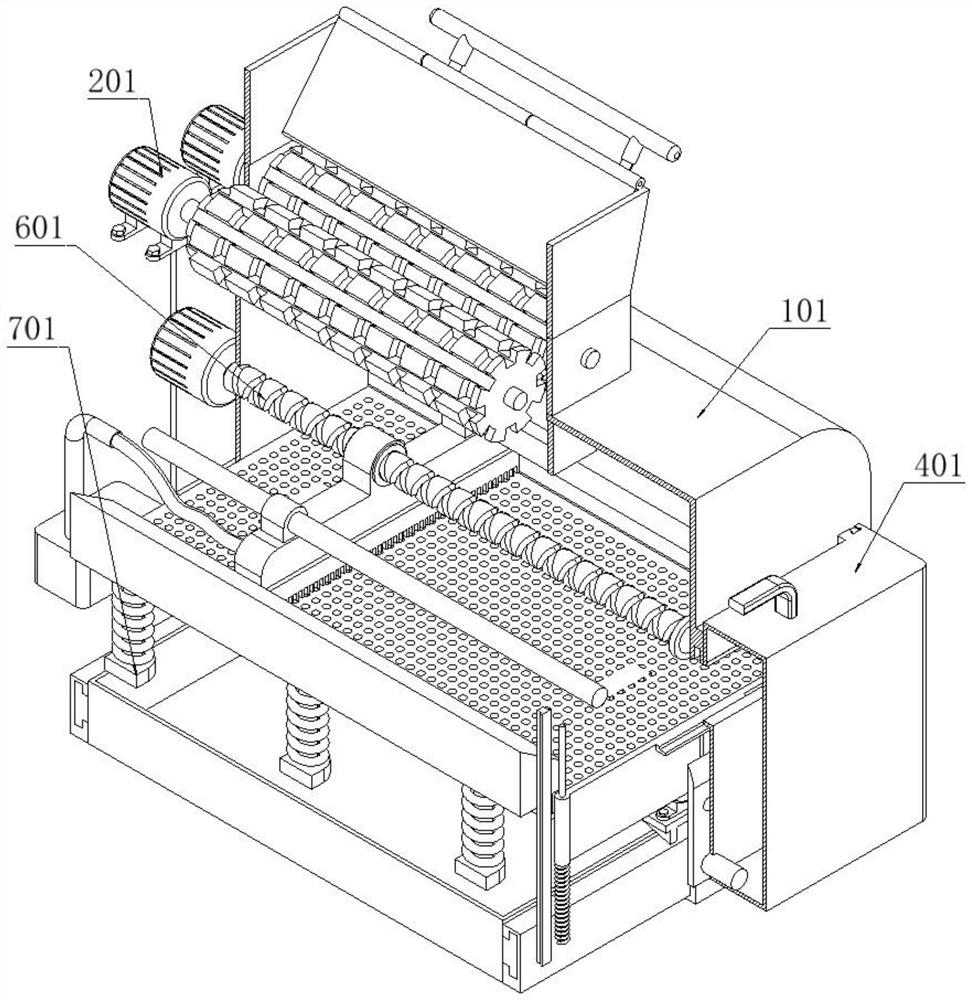

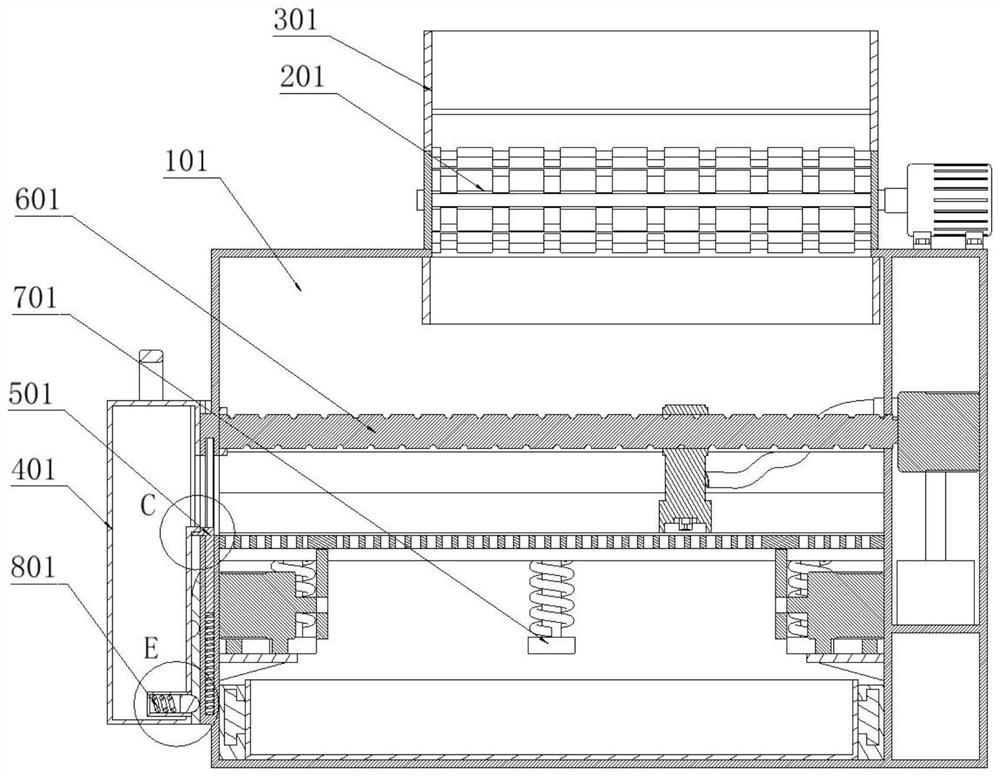

[0096] as attached figure 1 to attach Figure 12 Shown:

[0097] A kind of animal feed preparation process, by using crushing device to process animal feed, and then prepare suitable animal feed, and described crushing device comprises:

[0098] The housing device 1, the housing device 1 is fixedly connected to the bottom of the crushing device 2;

[0099] A split feeding device 3, which is fixedly connected to the top of the pulverizing device 2;

[0100] The material return bin device 4, the material return bin device 4 is slidably connected to the side of the housing device 1;

[0101] The box body sealing device 5, the box body sealing device 5 is fixedly connected to the side of the housing device 1;

[0102] The material return device 6, the material return device 6 is fixedly connected inside the housing device 1;

[0103] A particle screening device 7, the particle screening device 7 is fixedly connected inside the housing device 1;

[0104] The feed bin position...

Embodiment 2

[0150] as attached Figure 13 As shown, on the basis of Embodiment 1, other structures remain unchanged. This embodiment provides another contact form between the cam motor 707 and the crushing screen 706, and concave grooves are arranged on both sides of the crushing screen 706. The cam of the cam motor 707 is provided with a protruding block, and the cam is slidably connected to the groove of the crushing screen 706. In this way, the connection stability between the cam motor 707 and the crushing screen 706 can be greatly improved, and it is effective Reduced wear and tear, longer equipment life.

[0151] The animal feed preparation process specifically includes the following steps:

[0152] First place and install the equipment, and then start the equipment. After the equipment is started, the staff puts the raw materials on the split feeding device 3, and then pulls the arc-shaped feeding rod 305 after placing the raw materials on the split feeding device 3, and the raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com