Film prepared from waste thermoplastic elastomer and laminate thereof

A thermoplastic elastomer, thermoplastic elastic technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of the earth being overwhelmed, poor biodegradability, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

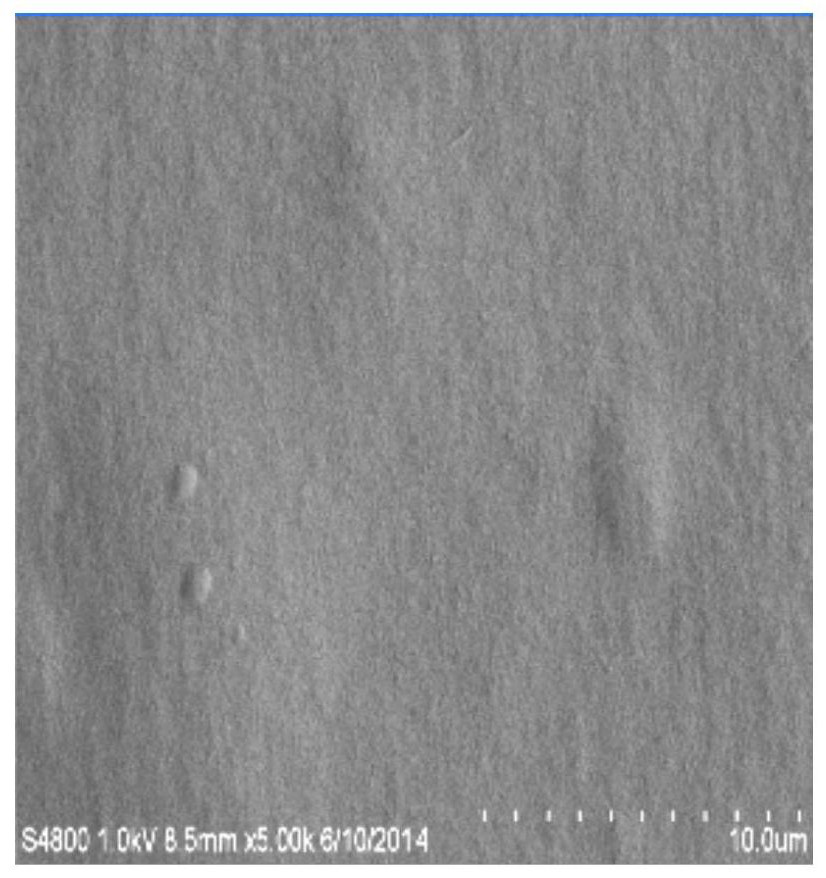

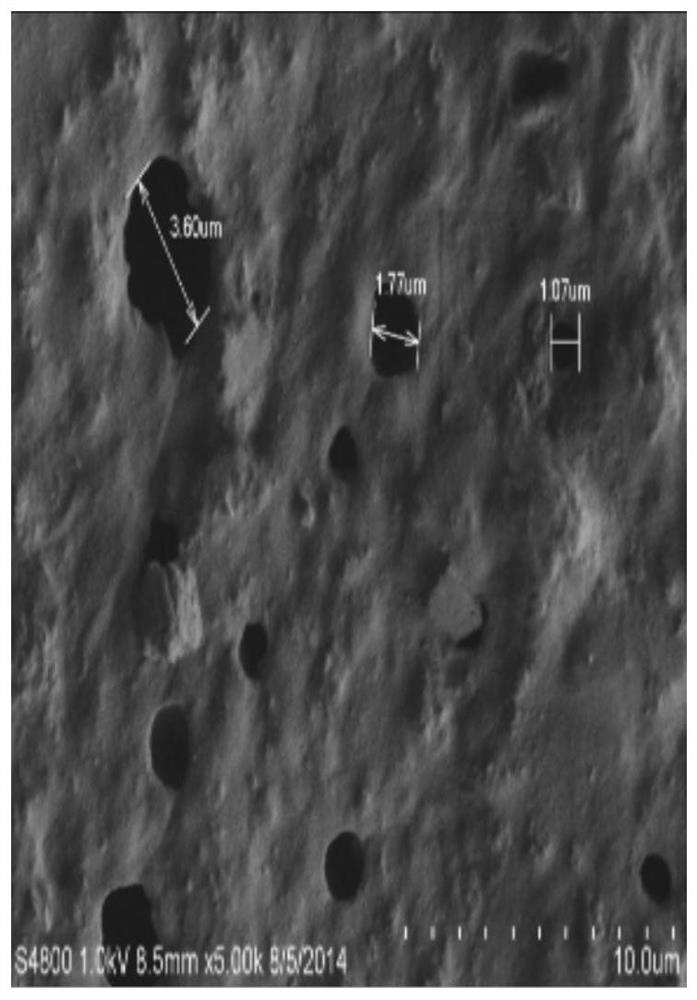

Image

Examples

preparation example Construction

[0094] Film preparation:

[0095] The melt of the above formula can flow out through the gap at the front end of the die to form a film. After leaving the die, the melt passes through a short gap and reaches the surface of the casting roll at a low temperature to be rapidly cooled and shaped; the melt of the above formula can also be The melt is blown out through the high-pressure air of the rotating die to form a tubular film. After leaving the die, the melt passes through a short gap and reaches the low-temperature casting roll surface to be cooled and shaped rapidly; hole forming), the flat plastic hard sheet is heated and softened, then vacuum adsorbed on the surface of the mold, and formed after cooling;

[0096] The above formula can also be plasticized to close to the viscous flow temperature through a series of horizontal rollers rotating in opposite directions, so that the material can be squeezed and stretched to become a thin sheet product with a certain thickness, ...

Embodiment 1

[0100] Example 1: Effect of Film Thickness

[0101] According to above-mentioned thin film preparation process, prepare a series of thin films, investigate the influence of the thickness of thin film on water vapor permeability, hydrostatic pressure, washing times (the hydrostatic pressure after how many times), the result is shown in Table 1, wherein prepared thin film is not Contains fresh thermoplastic elastomer;

[0102] Table 1 The relationship between the thickness and the performance of typical products

[0103]

[0104] The data in Table 1 shows that the thinner the film thickness, the higher the moisture permeability; the thicker the film thickness, the higher the hydrostatic pressure, and the smaller the impact of the number of washings on the hydrostatic pressure.

[0105] Therefore, when considering the application of the film of the present invention, the influence of thickness must be taken into consideration, and an appropriate thickness must be selected.

Embodiment 2

[0106] Example 2: Effect of Viscosity Modifier Content

[0107] According to the above-mentioned film preparation process, a series of films were prepared, and the influence of the dosage of viscosity modifier on moisture permeability, hydrostatic pressure, number of washings (hydrostatic pressure after how many times), hand feeling (characterized by elastic modulus) was investigated, and the result See Table 2, wherein the prepared film does not contain fresh thermoplastic elastomer, and the thickness of the film is 15 μm;

[0108] Table 2 Influence relationship of viscosity modifier on product performance

[0109]

[0110] From the data in Table 2, it can be found that for ordinary waste thermoplastic elastomers, if no viscosity regulator is added or the concentration of the regulator is too low, only liquid substances can be obtained during film production, and film formation or stable film cannot be formed. Of course, if the waste thermoplastic elastomer itself contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com