Low-energy-consumption and low-emission sintering method for multi-component gas medium composite injection

A gas medium and sintering method technology, applied in the direction of reducing gas emissions, can solve the problems of not being able to reduce the emission of multiple pollutants at the same time, the degree of emission reduction is limited, and the ability to reduce fossil fuel consumption is limited, achieving obvious economic advantages. Improved yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

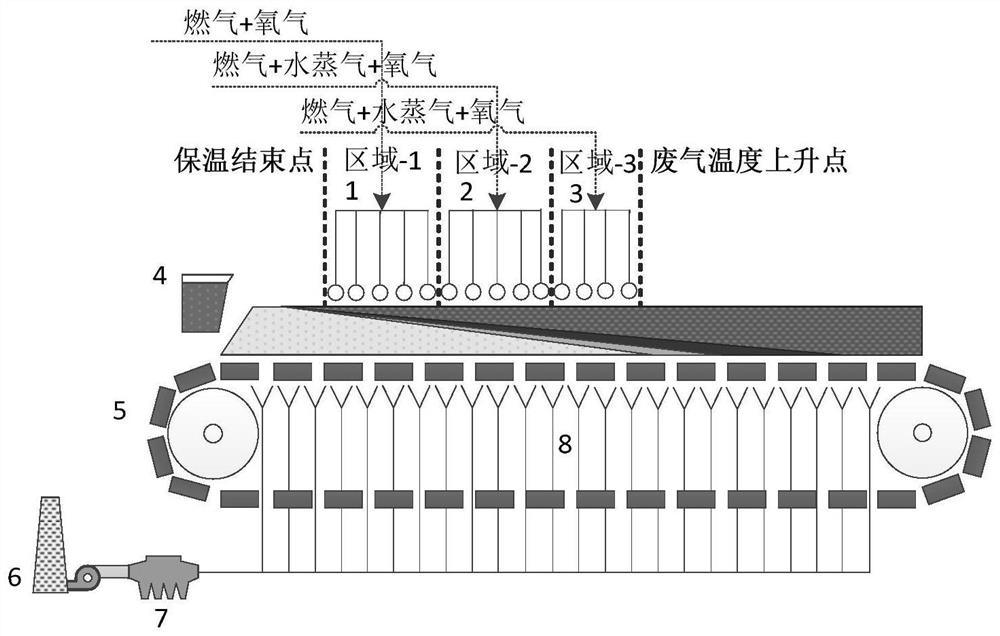

[0035] According to the mass ratio of 59.77% mixed iron ore, 4.27% dolomite, 5.57% limestone, 3.46% quicklime, 13.85% sintered ore return, 9.23% blast furnace return ore, and 3.85% coke powder (the chemical composition of the obtained sintered ore is TFe56. 08%, R1.80, MgO1.80%, CaO10.76%), after the materials are mixed and granulated, they are placed on the sintering surface, ignited for 1min at a temperature of 1050±50°C, held for 1min, and then heated under negative pressure Sintering is carried out under the condition of 15kPa. The sintering process is divided into three gas medium injection areas from the end of ignition to the beginning of exhaust gas temperature rise (see Figure-1 for the schematic diagram): Area-1 accounts for 40% of the entire interval, and the total concentration of the injected medium is 0.8% (70 % coke oven gas, 20% water vapor (temperature 200°C, pressure 1.57MPa), 10% oxygen); area-2 accounts for 40% of the entire interval, and the total concentr...

Embodiment -2

[0037] According to the mass ratio of 59.77% mixed iron ore, 4.27% dolomite, 5.57% limestone, 3.46% quicklime, 13.85% sintered ore return, 9.23% blast furnace return ore, and 3.85% coke powder (the chemical composition of the obtained sintered ore is TFe56. 08%, R1.80, MgO1.80%, CaO10.76%), after the materials are mixed and granulated, they are placed on the sintering surface, ignited for 1min at a temperature of 1050±50°C, held for 1min, and then heated under negative pressure Sintering is carried out under the condition of 15kPa. The sintering process is divided into three gas medium injection areas from the end of ignition to the beginning of exhaust gas temperature rise (see Figure-1 for the schematic diagram): Area-1 accounts for 50% of the entire interval, and the total concentration of injected medium is 1.0% (75 % converter gas, 10% water vapor (temperature 200°C, pressure 1.57MPa), 15% oxygen); zone-2 accounts for 40% of the entire interval, and the total concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com