Method for accurately positioning transverse moving trolley

A technology for traversing trolleys and precise positioning, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of low positioning accuracy of traversing trolleys, and achieve simple structure, convenient debugging, and high safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

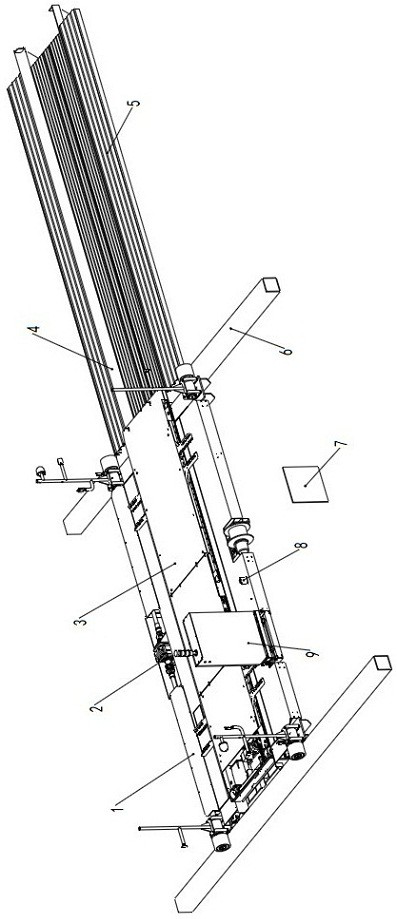

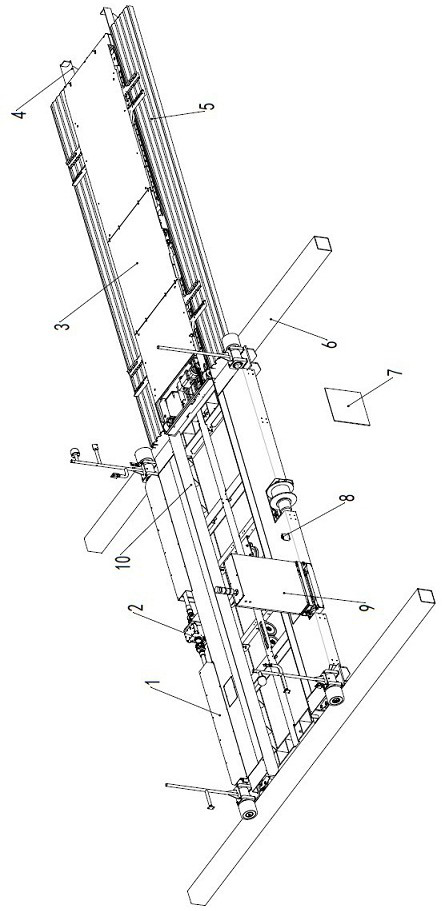

Image

Examples

Embodiment 1

[0033] A method for precise positioning of a traversing trolley, in which the specific steps for the traversing trolley to travel from any position to a designated position are as follows:

[0034] (1) Initial position: The traversing trolley is parked on the walking guide rail, and the light spot of the laser rangefinder of the traversing trolley is irradiated on the reflective plate at the end of the walking guide rail;

[0035](2) The control system controls the traversing trolley to move from the initial position to the designated parking space position in a position control manner. The target position is the calibration position where the traversing trolley is aligned with the parking space during commissioning. This target position is called the initial traversing trolley target position, the control system sends the encoder value and laser rangefinder value corresponding to the calibration position to the traverse trolley;

[0036] (3) When the traversing trolley approa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com