Sodium pyrosulfite production device

A technology for sodium metabisulfite and production equipment, which is applied in the preparation of alkali metal sulfites, alkali metal sulfites/sulfites, inorganic chemistry, etc. Poor environment and other problems, to achieve the effects of controllable product quality differences, small resistance, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

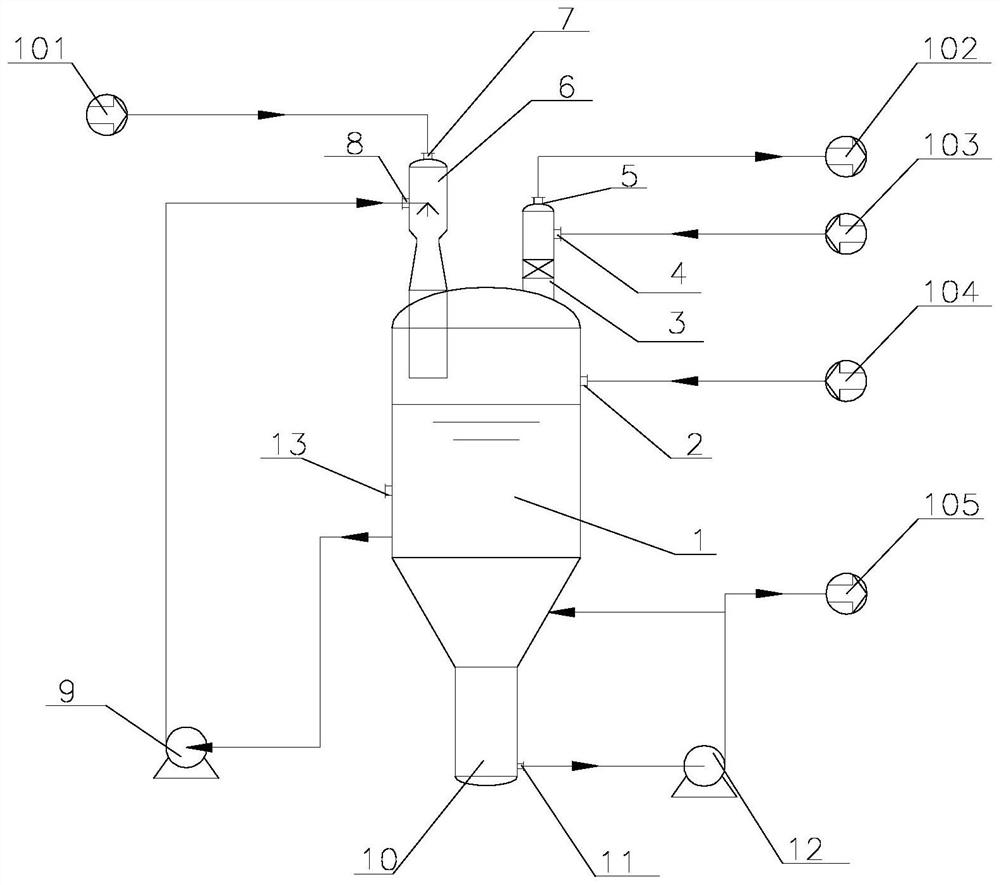

[0019] Such as figure 1 Shown, a kind of sodium metabisulfite production plant comprises crystallizer 1, and its top side is provided with defoamer 3, and the other side is provided with jet reactor 6, and its below is provided with crystal discharge section 10, and described crystal discharge section 10 is provided with a circulation pump 9 on one side and a crystal discharge pump 12 on the other side.

[0020] One side of the outer wall of the crystallizer 1 is provided with a raw material liquid interface 2 for regularly adding crystal feed liquid 105 to the crystallizer, and the other side is provided with a detection instrument interface 13 for reaction crystallization process control and reaction degree monitoring.

[0021] The top of the defoaming device 3 is provided with a reaction tail gas interface 5, and its side wall is provided with a flushing water interface 4 that facilitates the flow of flushing water 103. The top of the jet reactor 6 is provided with a feed g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com