Peanut oil capable of prolonging frying life and preparation method thereof

A technology for peanut oil and peanuts, which is applied in the field of NHP concentrate to inhibit the color reversion of peanut oil by heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

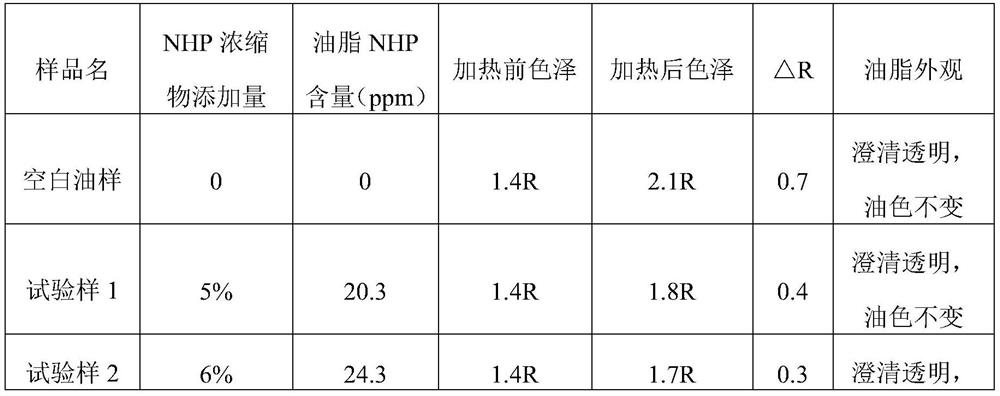

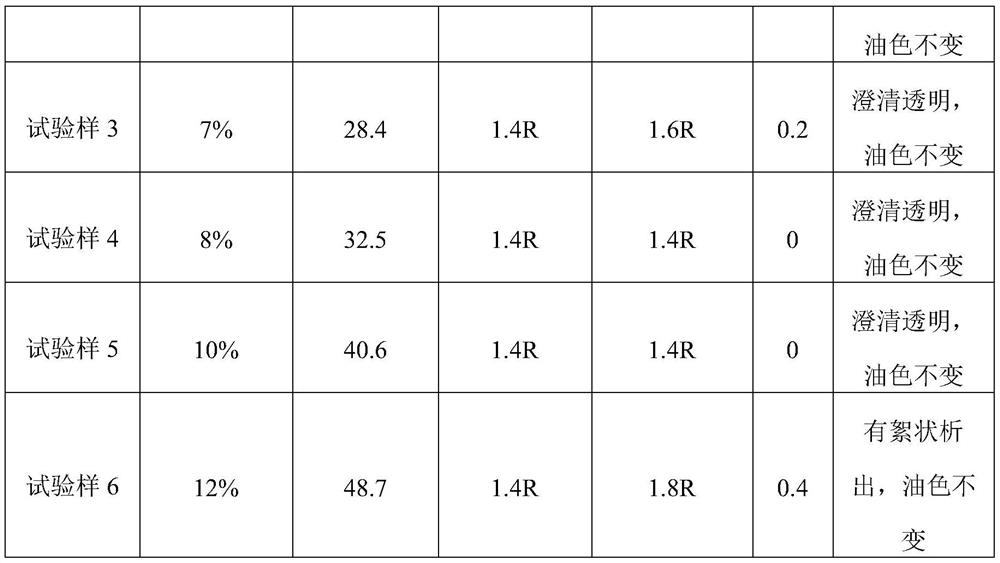

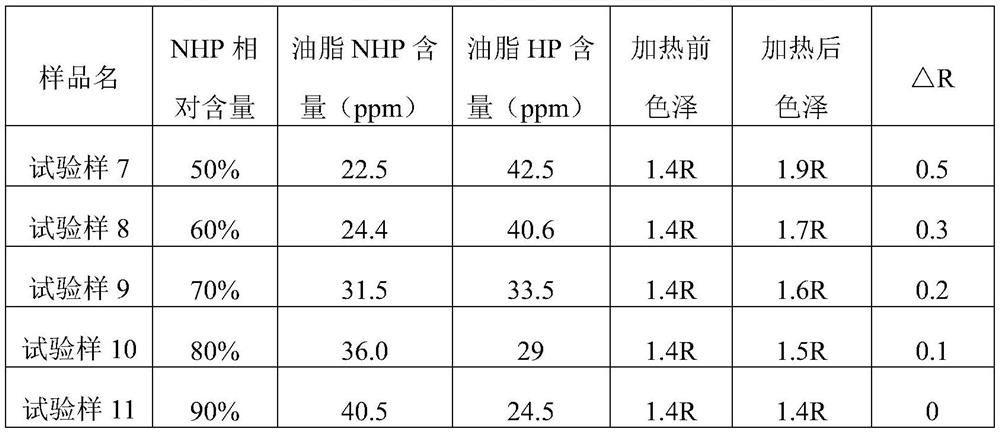

Examples

preparation example Construction

[0039] The method for preparing the NHP concentrate of the present invention includes: (1) removing the hydrated phospholipids in the leached peanut crude oil; (2) extracting the phospholipid components in the peanut oil obtained in step (1) with acetone; and (3) removing Acetone is removed to obtain the non-hydratable phospholipid concentrate.

[0040] The method for removing the hydrated phospholipids in the leached peanut crude oil is not particularly limited, and can be various methods known in the art that can remove the hydrated phospholipids in the oil. It should be understood that in the present invention, the leached peanut crude oil may still contain a small amount of hydrated phospholipids after being treated in the step of removing the hydrated phospholipids, that is, the peanut oil obtained by removing the hydrated phospholipids from the extracted peanut crude oil of the present invention is the removal of hydrated phospholipids. Peanut oil containing all or most of...

preparation example 1

[0068] Take 5L of peanuts to extract crude oil, heat to 50°C, add 0.08% oily citric acid solution (concentration: 50wt%), fully react for 30min (to convert part of NHP into HP), then add 5% of water, and hydrate for 10min , so that the hydrated phospholipids (HP) absorb water and flocculate. After cooling and filtering off the precipitate, the peanut oil with a part of HP removed is obtained. Add acetone whose mass is 10% of the mass of peanut oil to the peanut oil, dissolve and filter off the grease, take the precipitate and place it in a rotary evaporator, evaporate the acetone at 60°C to obtain the NHP concentrate. The total phosphorus content of the concentrate prepared by this method is 450ppm, and the relative content of NHP reaches 50%.

preparation example 2

[0070] Take 5L of peanut leaching crude oil, heat to 60°C, add citric acid solution (concentration: 50wt%) whose mass is 0.05% of the quality of peanut leaching crude oil, react for 15min (to convert part of NHP into HP), and then add 3% of water , hydrated for 10 minutes to make the hydrated phospholipid (HP) absorb water and flocculate. After cooling and filtering off the precipitate, the peanut oil with a part of HP removed was obtained. Add acetone with a mass of 5% of the mass of peanut oil to the peanut oil, dissolve and filter off the grease, take the precipitate and place it in a rotary evaporator, evaporate the acetone at 60°C to obtain the NHP concentrate. The total phosphorus content of the concentrate prepared by this method is 450ppm, and the relative content of NHP reaches 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com