Preparation of Hyperbranched Polyamine-Ester Flow Resin for Low-shrinkage Non-bis-gma-based Dental Restoration

A hyperbranched polymer-based dental technology, applied in the field of preparation of dental restoration materials, can solve the problems of increased polymerization shrinkage of the total content, no further exploration, etc., to achieve reduced polymerization shrinkage, excellent fluidity, and easy clinical The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

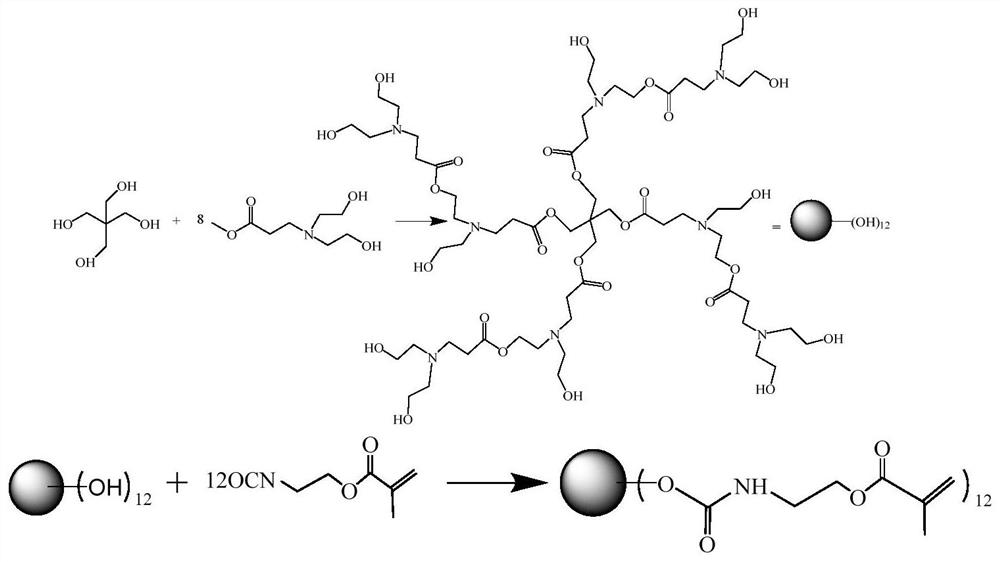

Method used

Image

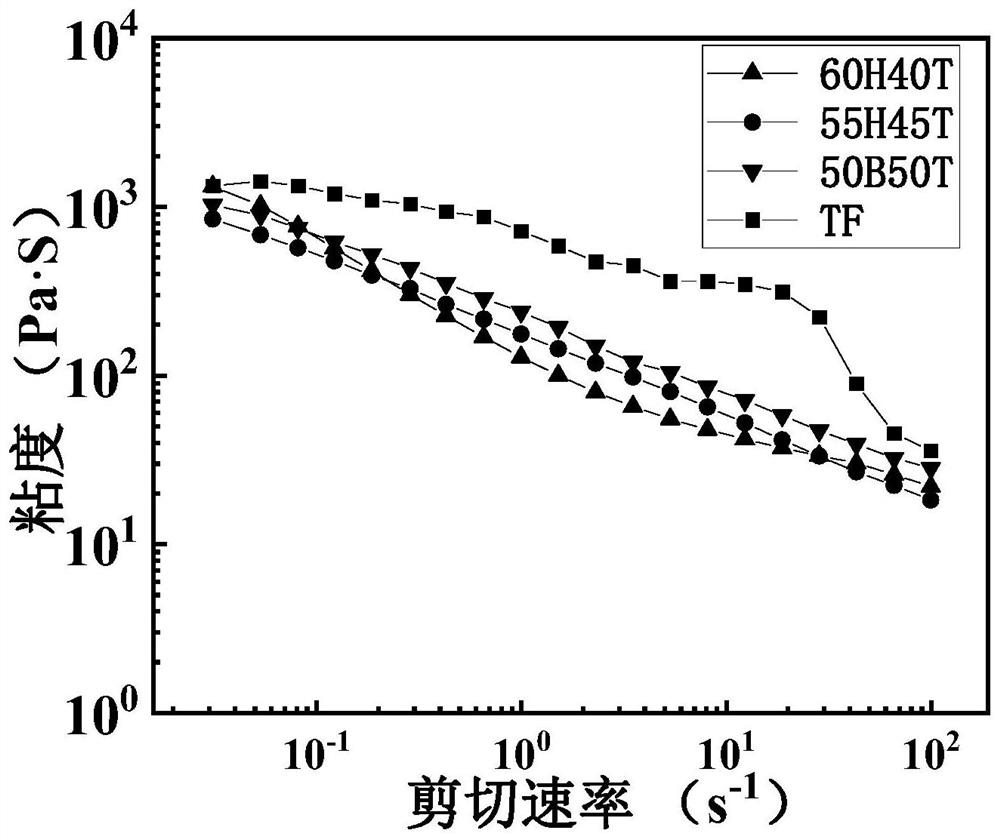

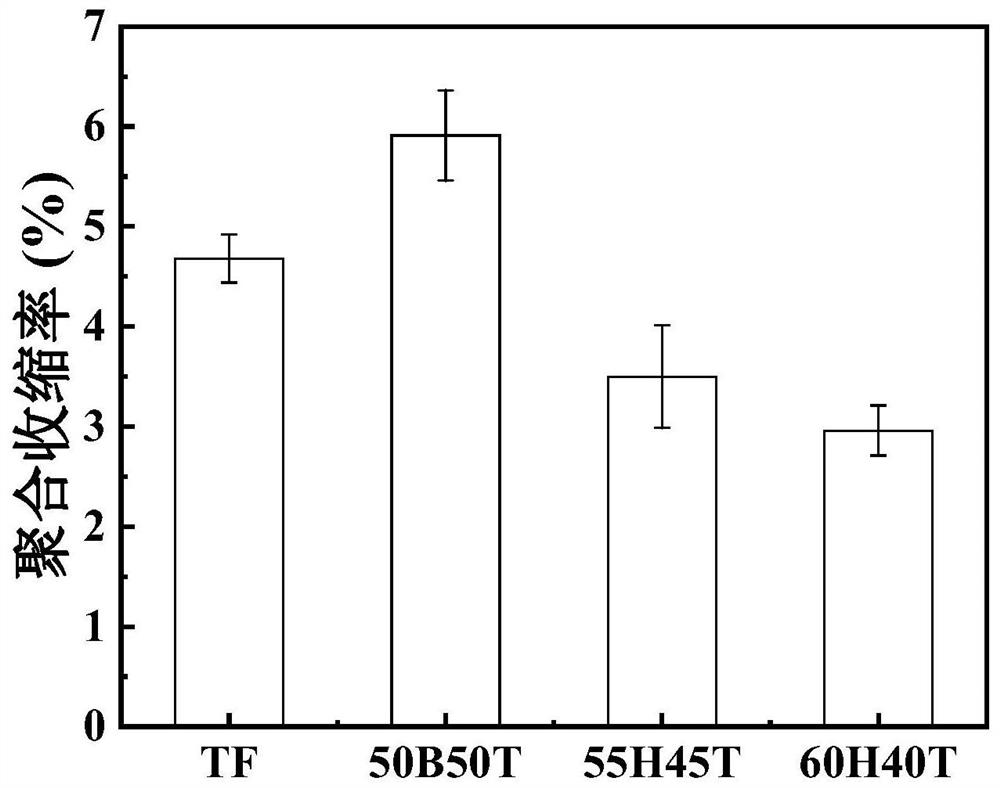

Examples

Embodiment 1

[0048] The preparation method of hyperbranched polyamine-ester flow resin for dental restoration with low shrinkage without Bis-GMA base, the specific process is as follows:

[0049] (1) Preparation of silanized inorganic fillers:

[0050] The inorganic filler is prepared by surface modification treatment. The specific method of surface modification treatment is as follows: add 50 g of inorganic filler to 600 mL of cyclohexane, stir and react in an oil bath at 40 °C for 20 min, and then add 5.5 mL of n-propylamine and 3.3 mL of n-propylamine in turn. mLγ-(methacryloyloxy)propyltrimethyloxysilane was stirred at 70 °C for 20 min. During the reaction, the stirring speed was always maintained at 650 r / min; Rinse with ethanol for several times, filter, and then dry in a vacuum oven at 60 °C for 24 h to obtain silanized inorganic filler;

[0051] Wherein, the inorganic filler is a mixture of micro-silica (particle size of 1 μm) and nano-silica (particle size of 20 nm) with a weight...

Embodiment 2

[0063] The preparation method of hyperbranched polyamine-ester flow resin for dental restoration with low shrinkage without Bis-GMA base, the specific process is as follows:

[0064] (1) Preparation of silanized inorganic fillers:

[0065] The inorganic filler is prepared by surface modification treatment. The specific method of surface modification treatment is as follows: add 50 g of inorganic filler to 600 mL of cyclohexane, stir and react in an oil bath at 40°C for 20 min, and then add 5.5 mL of n-propylamine and 3.3 mL of n-propylamine in turn. mLγ-(methacryloyloxy)propyltrimethyloxysilane was stirred and reacted at 70°C for 20min. During the reaction, the stirring speed was always maintained at 650r / min; Rinse with ethanol for several times, filter, and then dry in a vacuum oven at 60 °C for 24 h to obtain silanized inorganic filler;

[0066] Wherein, the inorganic filler is a mixture of micro-silica (particle size of 1 μm) and nano-silica (particle size of 20 nm) with ...

Embodiment 3

[0083] The preparation method of hyperbranched polyamine-ester flow resin for dental restoration with low shrinkage without Bis-GMA base, the specific process is as follows:

[0084] (1) Preparation of silanized inorganic fillers:

[0085] The inorganic filler is prepared by surface modification treatment. The specific method of surface modification treatment is as follows: add 50 g of inorganic filler to 600 mL of cyclohexane, stir and react in an oil bath at 30°C for 20 min, and then add 5.5 mL of n-propylamine and 3.3 mL of n-propylamine in turn. mL vinyltriethoxysilane was stirred at 60 °C for 30 min. During the reaction, the stirring speed was always kept at 650 r / min; the product was rotary-evaporated under reduced pressure, washed with n-hexane and ethanol for several times, filtered, and then Dry in a vacuum oven at 60°C for 24h to obtain silanized inorganic fillers;

[0086] Wherein, the inorganic filler is a mixture of micro-silica (particle size of 2 μm) and nano-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com