Method for recovering titanium from red mud leachate

A technology for leaching liquid and recovering titanium, which is applied in the direction of improving process efficiency, etc., can solve problems such as complex process and difficult separation of titanium, and achieve the effects of simple operation, increased hydrolysis rate, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

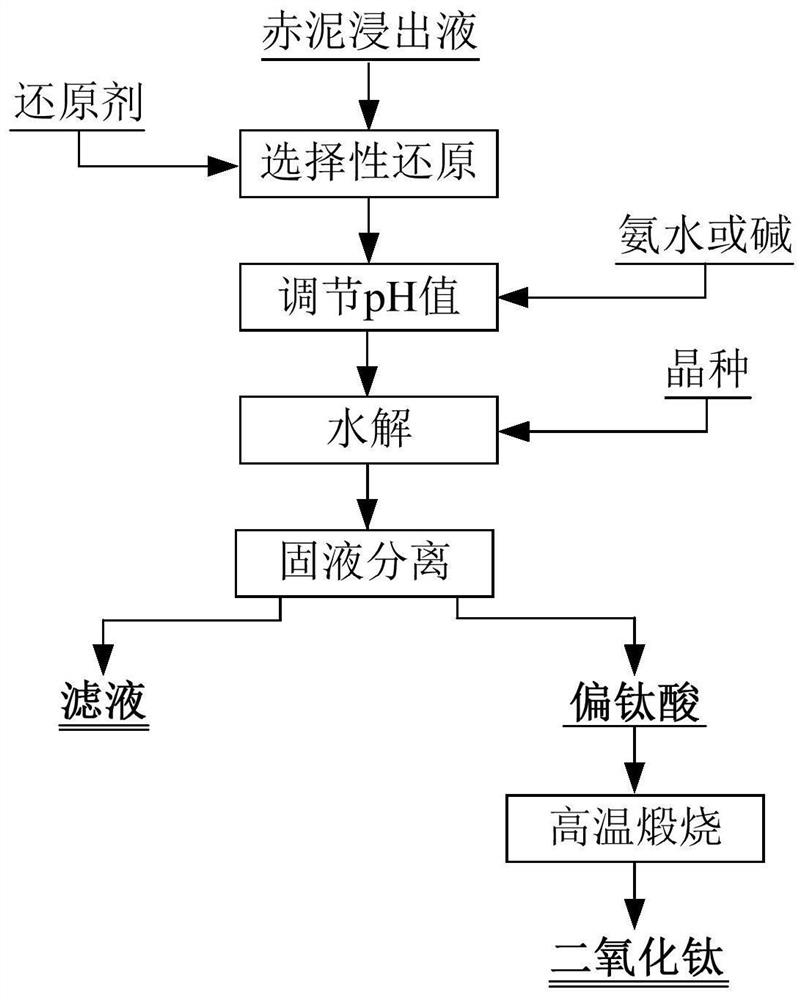

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for recovering titanium from red mud leachate, the method comprising the following steps:

[0039] (1) Mix the heated 1000mL red mud leaching solution with 2.76g iron powder, and the Fe in the red mud leaching solution 3+ reduced to Fe 2+ , the reduction temperature is 65°C and the time is 120min;

[0040] (2) Using ammonia water to adjust the pH of the red mud leachate after reduction in step (1) to 1.8;

[0041] (3) Heating the red mud leaching solution after the pH adjustment in step (2), adding metatitanic acid seed crystals at 100°C for 180 minutes of reaction, the concentration of metatitanic acid crystals added is 10g / L, and solid-liquid separation obtains filtrate and Metatitanic acid;

[0042] (4) Calcining the metatitanic acid obtained in step (3) at 500° C. for 60 minutes to obtain titanium dioxide.

[0043] Among them, the above-mentioned red mud leachate contains 5.44g / L aluminum, 2.01g / L titanium, 5.51g / L iron, 3.14g / L...

Embodiment 2

[0047] This embodiment provides a method for recovering titanium from red mud leachate, the method comprising the following steps:

[0048] (1) Mix the heated 1000mL red mud leaching solution with 4.14g iron powder, and the Fe in the red mud leaching solution 3+ reduced to Fe 2+ , the reduction temperature is 70°C and the time is 120min;

[0049] (2) Using ammonia water to adjust the pH of the red mud leachate after reduction in step (1) to 2.0;

[0050] (3) Heating the red mud leaching solution after pH adjustment in step (2), adding metatitanic acid seed crystals at 100°C for 150 minutes of reaction, the concentration of metatitanic acid crystals added was 15g / L, and solid-liquid separation obtained filtrate and Metatitanic acid;

[0051] (4) Calcining the metatitanic acid obtained in step (3) at 500° C. for 60 minutes to obtain titanium dioxide.

[0052] Among them, the above-mentioned red mud leachate contains 5.44g / L aluminum, 2.01g / L titanium, 5.51g / L iron, 3.14g / L s...

Embodiment 3

[0056] This embodiment provides a method for recovering titanium from red mud leachate, the method comprising the following steps:

[0057] (1) Mix the heated 1000mL red mud leaching solution with 1.38g iron powder, and the Fe in the red mud leaching solution 3+ reduced to Fe 2+ , the reduction temperature is 60°C and the time is 90min;

[0058] (2) using ammonia water to adjust the pH of the red mud leachate after reduction in step (1) to 1.6;

[0059] (3) Heating the red mud leaching solution after pH adjustment in step (2), adding metatitanic acid seed crystals at 100°C for reaction for 240 minutes, the concentration of metatitanic acid crystals added is 5g / L, and solid-liquid separation obtains filtrate and Metatitanic acid;

[0060] (4) Calcining the metatitanic acid obtained in step (3) at 400° C. for 120 minutes to obtain titanium dioxide.

[0061] Among them, the above-mentioned red mud leachate contains 5.44g / L aluminum, 2.01g / L titanium, 5.51g / L iron, 3.14g / L sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com