Combustion device with low nitrogen oxide emission

A low-nitrogen oxide, combustion device technology, applied in the safety device of the combustion chamber, indirect carbon dioxide emission reduction, combustion chamber and other directions, can solve the problems of reduced boiler efficiency, high water content, poor denitrification effect, etc., to reduce pollution the possible effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

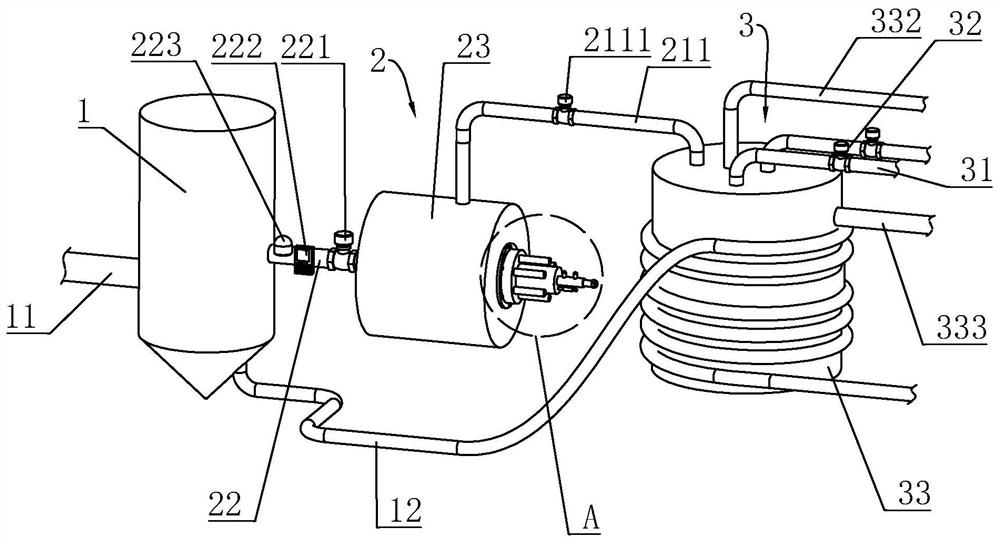

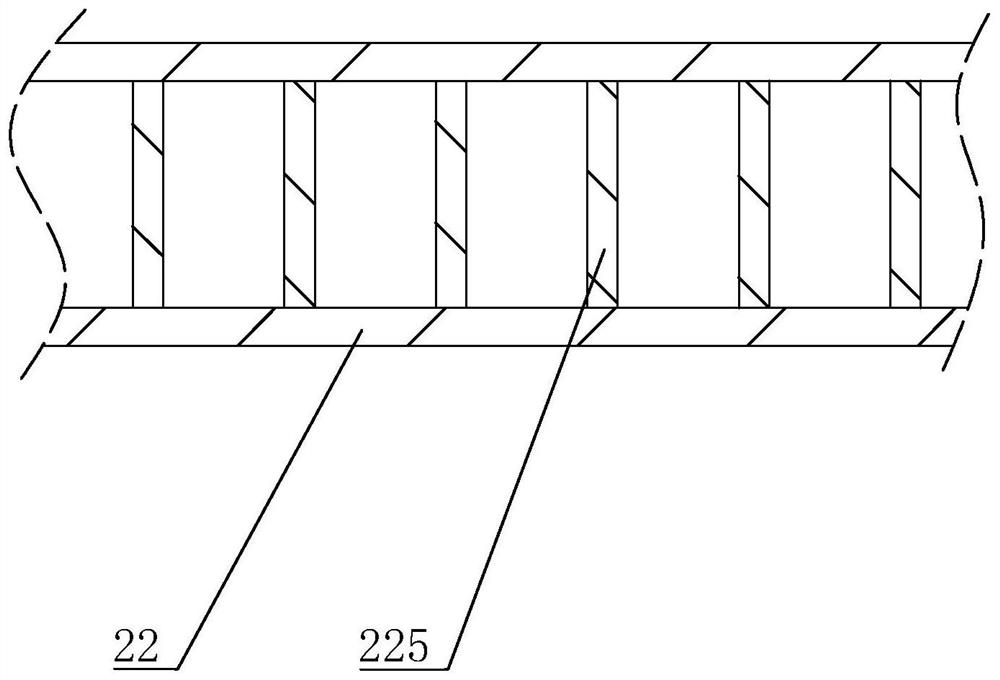

[0033] Example: Refer to figure 1 The combustion device discharged is disclosed in the present invention, including the furnace body 1, and the side wall of the furnace body 1 is provided on the side wall of the furnace body 1, and in the side wall of the furnace body 1, in the air pipe 12 The air duct 12 is a hose, and an interior hollow reduction chamber 3 is provided externally, and a combustion mechanism 2 for secondary combustion of the flue gas is provided between the furnace body 1 and the reduction chamber 3 is provided.

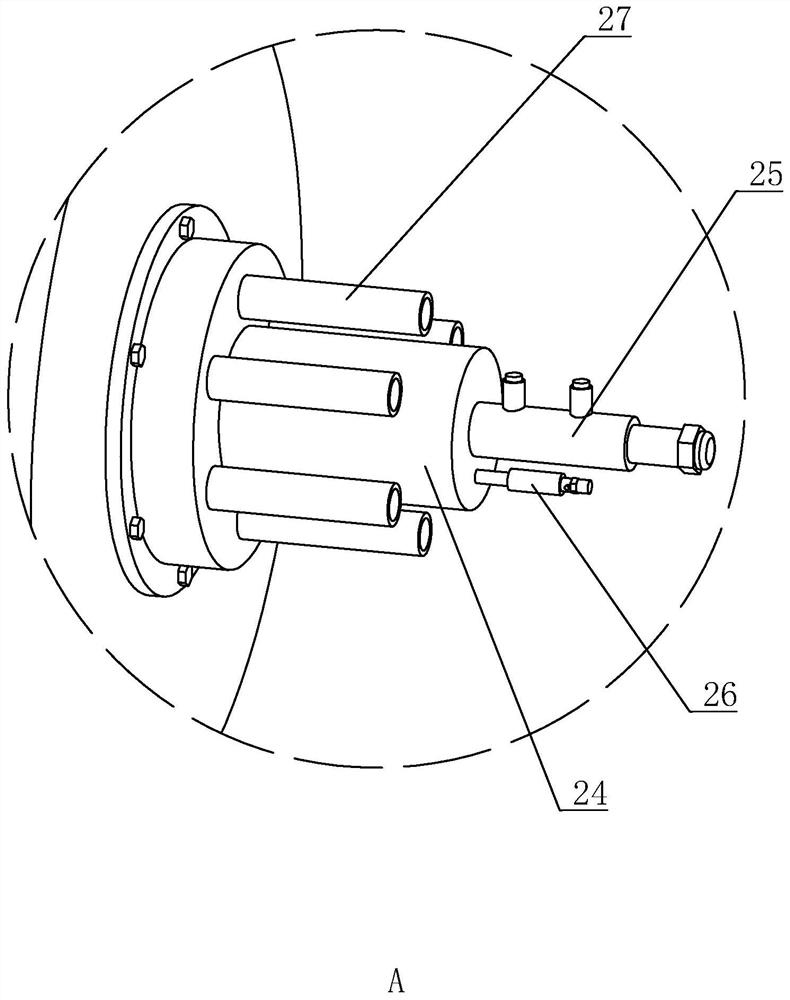

[0034] Refer figure 1 with figure 2 The combustion mechanism 2 includes a combustion chamber 23, and a fuel tube 24, a UV flame detector 25 mounted within the fuel tube 24, an igniter 26, a fuel tube 24, a UV flame detector 25, an igniter 26, located above the fuel tube 24. All sides from the combustion chamber 23 depuses from the furnace body 1 into the combustion chamber 23, and the combustion chamber 23 is connected to one side of the gas pipe to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com