Gas film heat insulation and cooling device for gas source of solid fuel gas generator

A gas generator, heat insulation and cooling technology, which is applied in the direction of aerospace vehicle heat protection devices, aerospace safety/emergency devices, projectiles, etc., can solve the problems of complex aerodynamic structure, short heat protection time, and large space occupation, and achieve Simplify the air source supply system, reduce the effect of pneumatic heating, and achieve high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

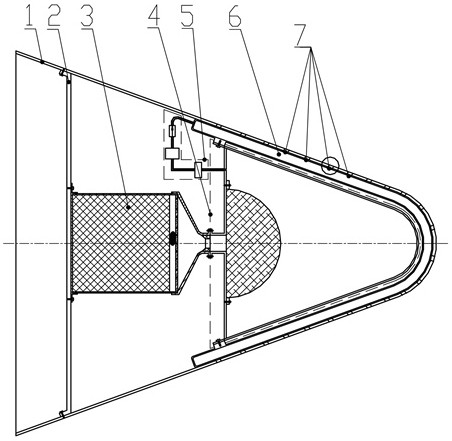

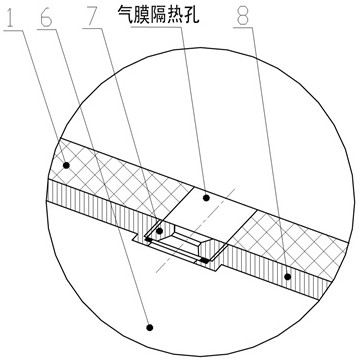

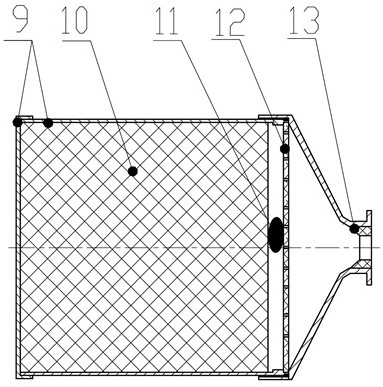

[0022] The structure of the air film heat insulation and cooling device proposed by the present invention is as follows: figure 1 As shown, it mainly consists of aircraft hood (1), generator fixing bracket (2), solid gas generator (3), gas filtering and rectifying storage tank (4), gas regulation and delivery system (5) and gas distribution device (6) composition; wherein the generator fixing bracket (2) is fastened on the inner wall of the aircraft hood (1) on the upper and lower sides with screws, and the solid gas generator (3) is fastened to the generator fixing bracket (2) with bolts The right side of the middle part; the gas filter and rectification storage tank (4) is conical in shape with a blunt head, located on the right side of the solid gas generator (3), connected with the solid gas generator (3) by a flange and O-ring seal is used; the gas adjustment and delivery system (5) is located on the outside of the solid gas generator (3), on the left side of the gas filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com