Device and method for sampling SO3 in flue gas of coal-fired unit

A technology of sampling device and coal-fired unit, applied in sampling device, measuring device, sampling and other directions, can solve the problems of short lifespan of sampling tube, low sampling efficiency, easy entry of particulate matter into sampling tube, etc., so as to reduce sampling loss and improve sampling efficiency, reducing the effect of fly ash deposition on the tube wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

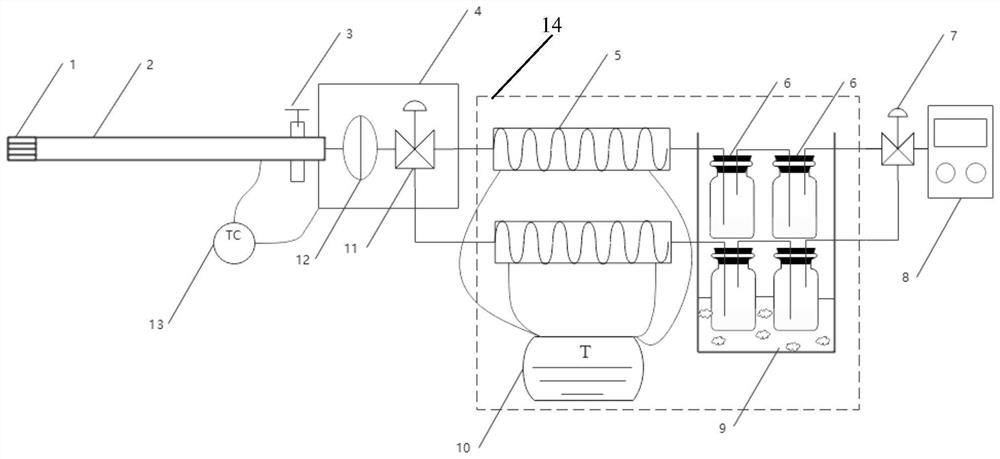

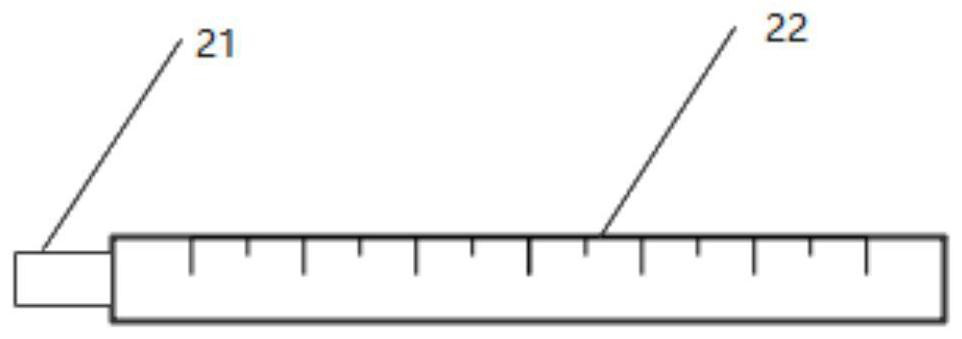

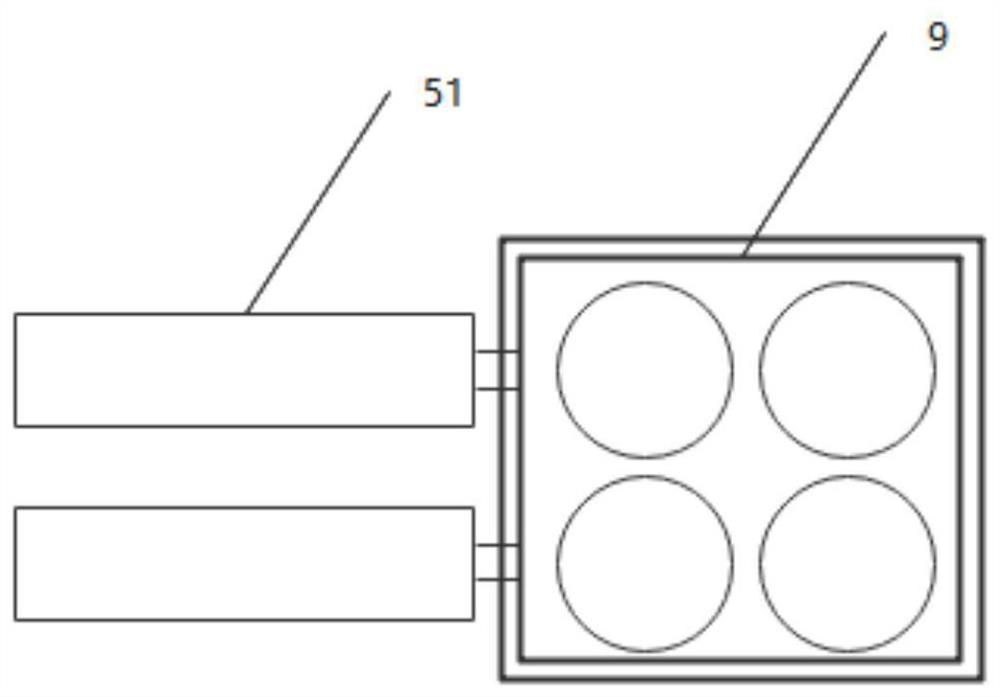

[0030] SO in the flue gas of a coal-fired unit 3 sampling devices such as figure 1 As shown, it includes: sampling gun rod 2, depth positioning ring 3, heating box 4, serpentine collection tube 5, gas washing bottle 6, sampling pump (chemical titration sampling pump) 8, ice bath box 9, water bath heating box 10, temperature controller 13; wherein the sampling gun rod 2 is provided with a depth positioning ring 3, and the sampling gun rod 2 is provided with a sliding device matched with the depth positioning ring 3, and the depth positioning ring 3 can slide to a specific position on the sampling gun rod 2; The gun shaft 2 is also provided with a locking valve, which is used to fix the depth positioning ring 3 on the sampling gun shaft 2; the sampling gun shaft 2 is connected in series with the membrane filter 12 and the front three-way valve 11 in the heating box 4; the temperature controller 13 Connect the sampling gun rod 2 and the heating box 4; the heating box 4 exposes t...

Embodiment 2

[0039] On the basis of Example 1, SO in the flue gas of a coal-fired unit 3 The working method of the sampling device specifically comprises the following steps:

[0040] Step 1, start the sampling pump 8, check the air tightness of the sampling device, and arrange the sampling points according to the sampling standard after the sampling device has no abnormal air tightness; slide the depth positioning ring 3 (diameter 200mm) on the sampling gun rod 2 to the set point. Fix the position, use the locking valve to fix the depth positioning ring 3 on the sampling gun rod 2, the depth positioning ring 3 is used to locate the depth of the sampling point and can be used to seal the sampling hole to avoid the large swing of the gun body during the sampling process;

[0041] Step 2. Insert the sampling gun rod 2 into the sampling hole as a whole to ensure that the sampling hole is well sealed; heat all the silica gel in one group of absorption units 14 connected to the outlet of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com