Direct-current heating single-channel gas heat exchange experimental device

An experimental device and single-channel technology, applied in the field of energy and power, to avoid high-temperature oxidation and increase the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

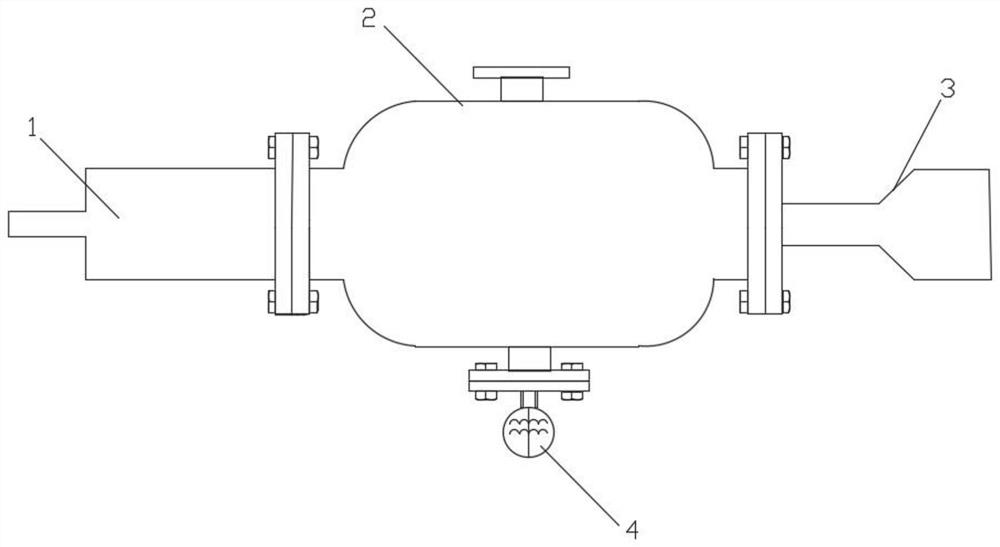

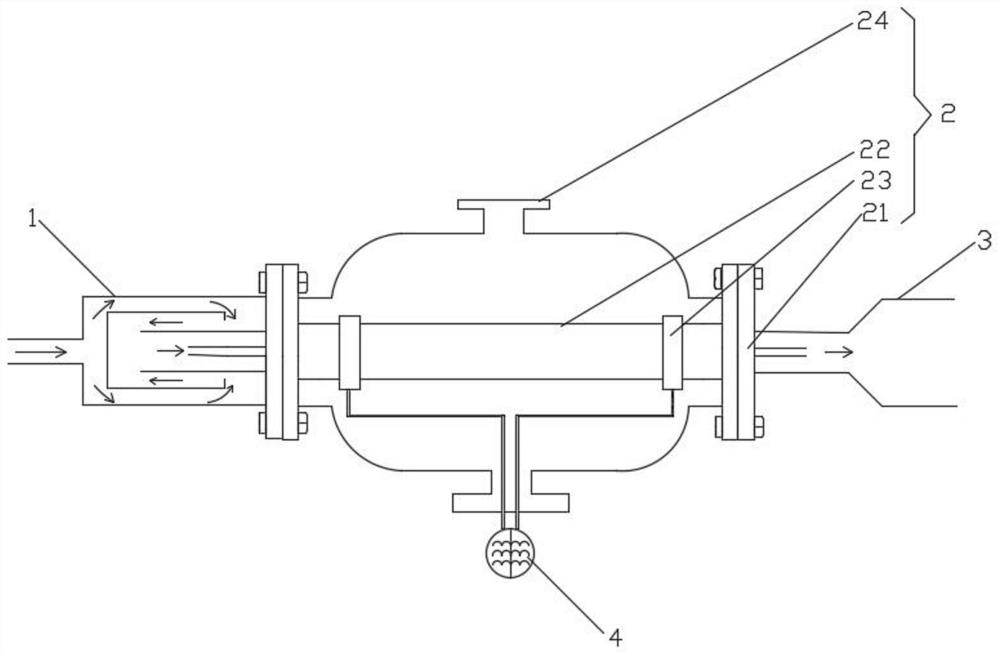

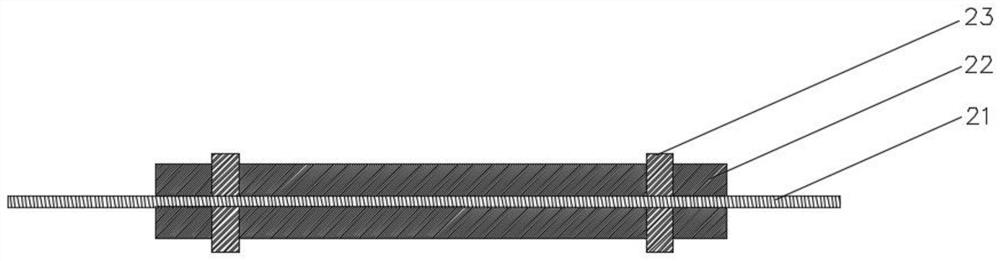

[0030] refer to Figure 1-3 Shown is a direct current heating single-channel gas heat exchange experimental device, including an air inlet tube 1, an experimental device main body 2, an outlet tube 3 and a DC power supply 4; wherein the top of the experimental device main body 2 is provided with an observation window, and the bottom of the experimental device main body The air inlet tube 1 and the air outlet tube 3 are tightly connected to the two ends of the main body 2 of the experimental device through flanges, wherein the air inlet tube 1 is provided with a baffle channel inside, and the gas working fluid injected into the baffle channel It is hydrogen, helium, argon, nitrogen, carbon dioxide and helium-xenon mixed gas, and the punching tube 3 is a gradual expander. The top of the experimental device main body 2 is provided with an observation window 24, and the inside is provided with an experimental tube 21, a thermal insulation sleeve 22 and two electrodes 23; The ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com