A single-mode fiber with a large core diameter

A single-mode optical fiber and large core technology, which is applied to multi-layer core/clad optical fibers, clad optical fibers, and optics, can solve the problems of uncontrollable manufacturing process, high difficulty, and poor core-clad refractive index. Multiple design degrees of freedom and process control dimensions, low-cost large-scale production, and the effect of reducing doping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

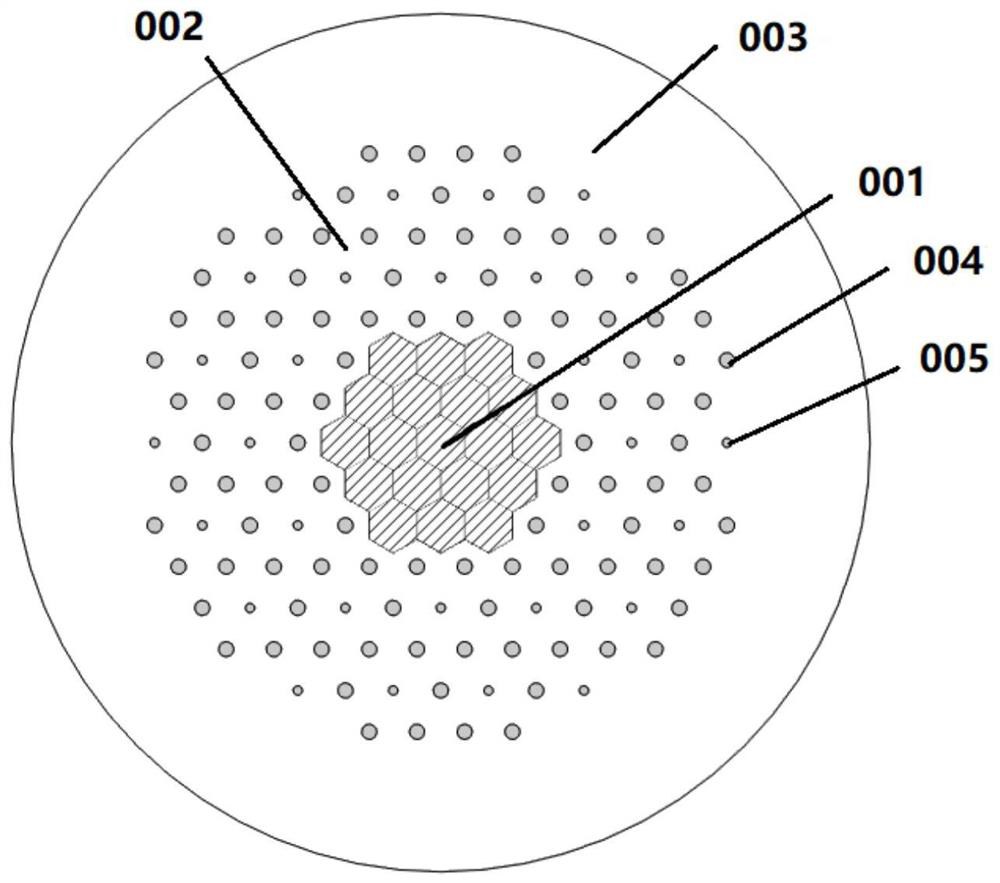

[0050] refer to figure 1 , figure 1 A schematic cross-sectional view of a single-mode optical fiber with a large core diameter provided in Embodiment 1 of the present invention.

[0051] The single-mode optical fiber with large core diameter provided in Example 1 includes:

[0052] The fiber core 001 located in the center of the optical fiber for transmitting signal light, the fiber core 001 is formed by stacking 19 rare earth-doped quartz glass rods;

[0053] The inner cladding of the fiber core 001 is covered, and the inner cladding includes an inner cladding inner ring 002 and an inner cladding outer ring 003. The inner cladding outer ring 003 is a homogeneous medium of pure silica glass, but no air holes are provided; the inner cladding inner ring 002 is made of pure silica glass. The capillaries made of quartz glass are piled up. It is obvious that there are two types of air holes in the capillaries in the inner cladding inner ring 002, namely the first type of air hole...

Embodiment 2

[0057] refer to Figure 4 , Figure 4 A schematic cross-sectional view of a single-mode optical fiber with a large core diameter provided in Embodiment 2 of the present invention.

[0058] The single-mode fiber with a large core diameter provided in Example 2 includes:

[0059] The fiber core 001 located in the center of the optical fiber for transmitting signal light, the fiber core 001 is formed by stacking 7 rare-earth-doped quartz glass rods;

[0060] Coating the inner cladding of the core 001, the inner cladding includes the inner cladding inner ring 002 and the inner cladding outer ring 003, the inner cladding outer ring 003 is made of pure quartz glass, but no air holes are provided; the inner cladding inner ring 002 is made of pure quartz glass. Quartz glass is formed by stacking capillaries. It is obvious that there are two types of air holes in the inner cladding inner ring 002 due to the accumulation of capillaries, namely the first type of air holes 004 and the sec...

Embodiment 3

[0062] refer to Figure 5 , Figure 5 It is a schematic cross-sectional view of the single-mode optical fiber with a large core diameter provided in Embodiment 3 of the present invention.

[0063] The single-mode optical fiber with large core diameter provided in Example 3 includes:

[0064] The core 001 is located in the center of the optical fiber and is used to transmit signal light. The core 001 is made up of 7 rare-earth-doped quartz glass rods; Circle 003, the inner cladding outer circle 003 is a homogeneous medium of pure quartz glass, but no air holes are provided; the inner cladding inner circle 002 is formed by the accumulation of capillaries made of pure quartz glass, and it is obvious that the inner cladding inner circle 002 exists due to the accumulation of capillaries. The two types of air holes are the first type of air holes 004 and the second type of air holes 005 , wherein the number of the first type of air holes 004 is greater than the number of the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com