Lightweight design method and structure for movable arm of loading machine

A lightweight design and manoeuvring arm technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve rare problems, achieve the effect of accurate force transmission path, improve product competitiveness, and rational layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Further detailed description will be described in conjunction with the accompanying drawings. The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the invention.

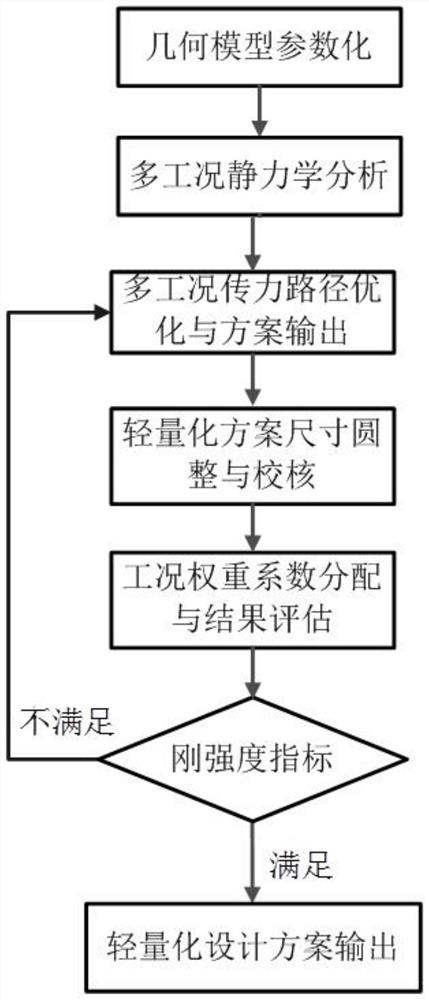

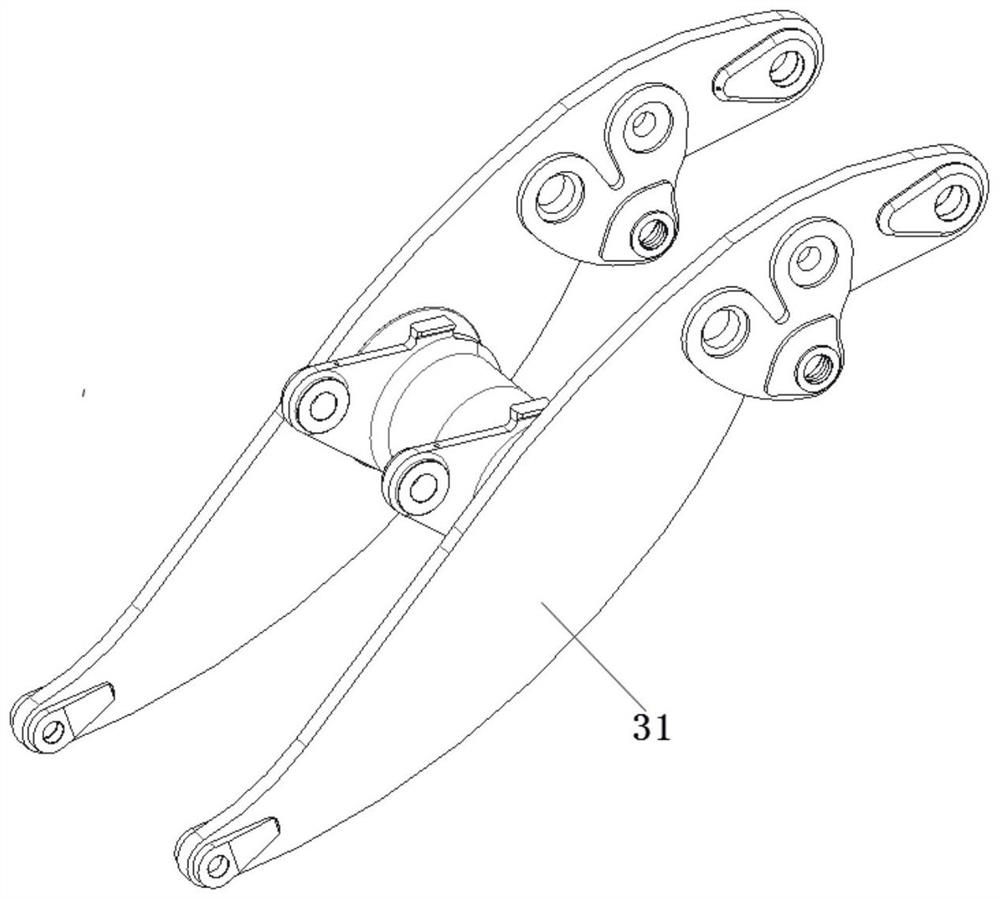

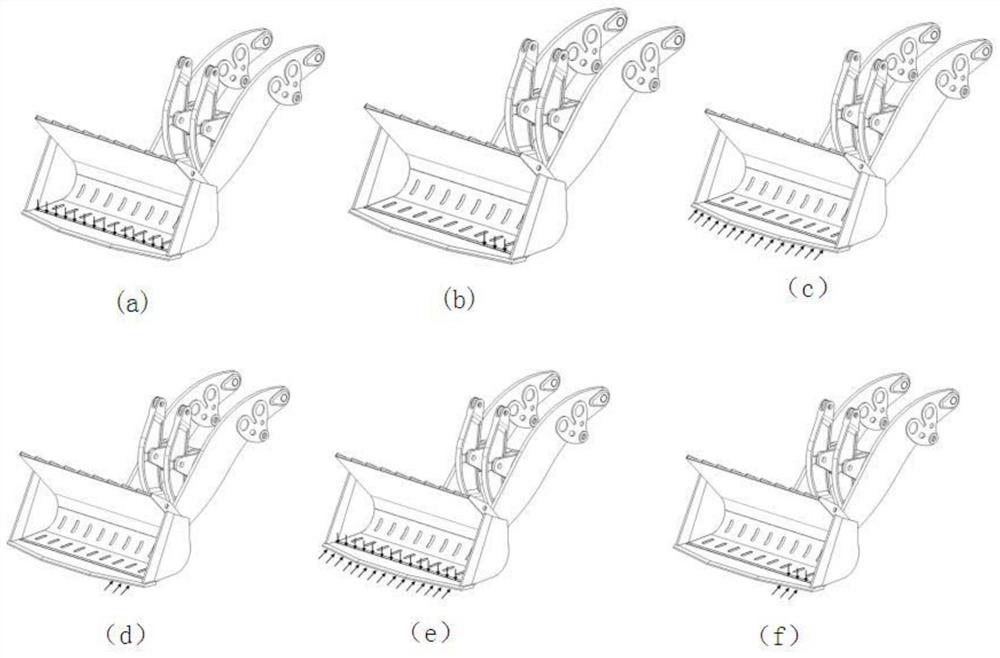

[0057] Such as Figure 1 ~ 3 One embodiment as shown, a light quantification design method of loading a motor arm, using the boom plate material to be Q550D, its yield limit is 550 MPa, and the maximum stress of the boom is 520 MPa in a single-working condition; including the following step:

[0058] Step 1: Dugered arm structure geometric model discretization, taking a hexahedral solid unit on the arm structure, establishing a finite element analysis model;

[0059] Step 2: Under the finite element analysis model, the initial structure of the boom structure under each working condition is subjected to finite element static analysis, and the initial value of the rigidity index is obtained;

[0060] Step 3: Based on the finite element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com