Non-contact electromagnetic ultrasonic auxiliary welding equipment

An electromagnetic ultrasonic and auxiliary welding technology, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of cracking of brittle materials such as ceramics, difficulty in obtaining welded joints, and difficult temperature control, so as to reduce heat loss and avoid cracking. Problems, effect of parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

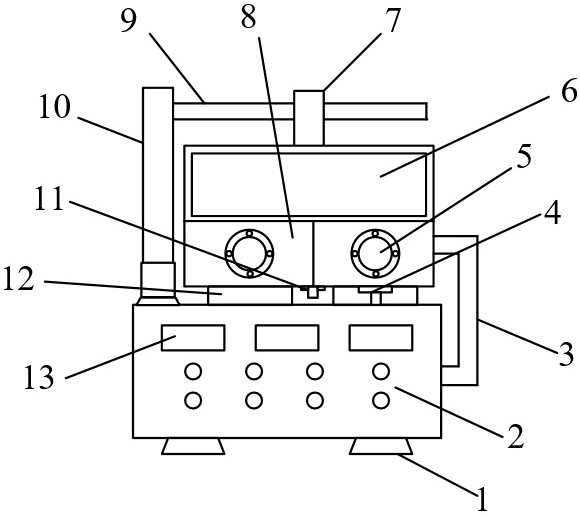

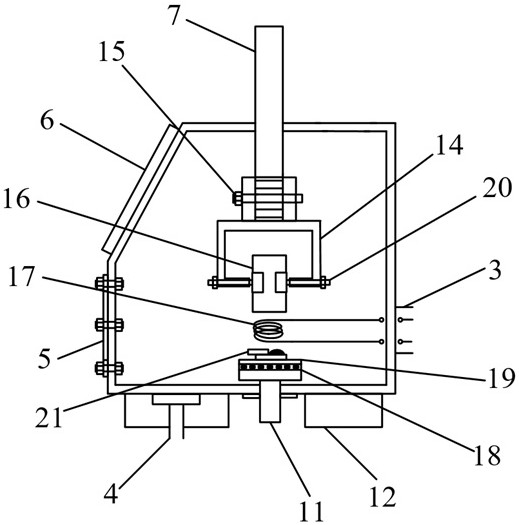

[0026] combine figure 1 , figure 2 As shown, this non-contact electromagnetic ultrasonic assisted welding equipment control system, heat preservation and temperature measurement system, electromagnetic system, heating system and operating system specifically include a console 2, the left part of which is a heat preservation room 8 on the console 2 is a column 10, Two glove interfaces 5 are installed at the front of the heat preservation chamber 8, which can realize the assembly of the welding sample 21 in a high-temperature environment. An observation window 6 is installed above the glove interface 5, which can monitor the assembly and brazing process of the welding sample 21 in real time. Observe, the thermocouple 4 is installed in the lower right part of the heat preservation chamber 8, and the thermocouple 4 is connected to the console 2. The connecting wire is placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com