Super-absorbent ES composite fiber and preparation method thereof

A composite fiber and superabsorbent technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of mechanical properties such as mechanical strength decline, failure to meet the use requirements, and no superabsorption, etc., to achieve excellent mechanical properties , fast speed, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

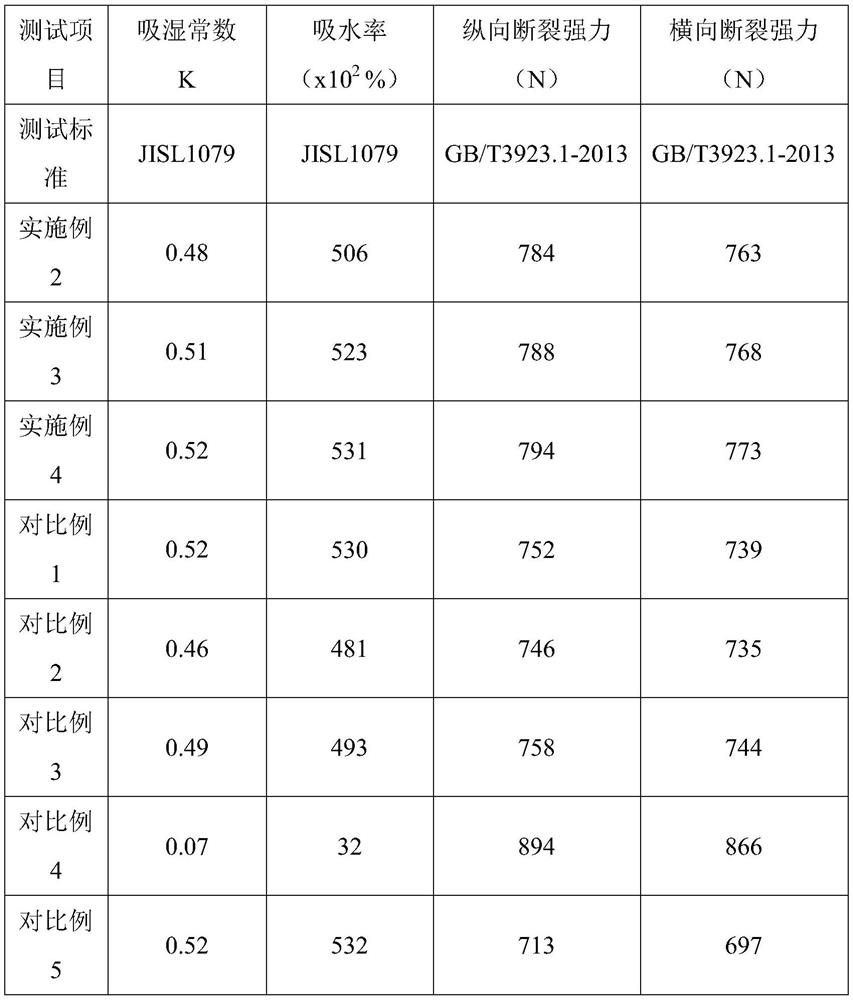

Examples

Embodiment 1

[0040] A superabsorbent ES composite fiber, the superabsorbent ES composite fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer;

[0041] Wherein, the core layer is made of the following raw materials in parts by weight: 80-90 parts of polypropylene, 10-14 parts of polyethylene, 7-10 parts of maleic anhydride grafted polypropylene, 3-5 parts of nano-silica ;

[0042]The skin layer is made of the following raw materials in parts by weight: 60-70 parts of polyethylene, 11-15 parts of ethylene-vinyl acetate copolymer, 6-9 parts of dibutyl maleate grafted polypropylene, sodium polyacrylate high 18-23 parts of water-absorbing resin, 3-5 parts of nano silicon dioxide, and 5-8 parts of aluminum trichloride.

[0043] In this embodiment, the volume ratio of the core layer and the skin layer is preferably 1:2.63-2.85.

[0044] In this embodiment, the core layer is preferably made of the following raw materials in parts by weight: 85 parts of polyp...

Embodiment 2

[0057] A superabsorbent ES composite fiber, the superabsorbent ES composite fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer;

[0058] Wherein, the core layer is made of raw materials including the following parts by weight: 80 parts of polypropylene, 10 parts of polyethylene, 7 parts of maleic anhydride grafted polypropylene, and 3 parts of nano-silica;

[0059] The skin layer is made of the following raw materials in parts by weight: 60 parts of polyethylene, 11 parts of ethylene-vinyl acetate copolymer, 6 parts of dibutyl maleate grafted polypropylene, 18 parts of sodium polyacrylate superabsorbent resin, 3 parts of nano silicon dioxide, 5 parts of aluminum trichloride.

[0060] In this embodiment, the volume ratio of the core layer and the skin layer is 1:2.63.

[0061] In this embodiment, the polyethylene is metallocene linear low density polyethylene.

[0062] In this embodiment, the aluminum trichloride is nano aluminum trichlo...

Embodiment 3

[0072] A superabsorbent ES composite fiber, the superabsorbent ES composite fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer;

[0073] Wherein, the core layer is made of raw materials comprising the following parts by weight: 90 parts of polypropylene, 14 parts of polyethylene, 10 parts of maleic anhydride grafted polypropylene, and 5 parts of nano-silica;

[0074] The skin layer is made of the following raw materials in parts by weight: 70 parts of polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 9 parts of dibutyl maleate grafted polypropylene, 23 parts of sodium polyacrylate superabsorbent resin, 5 parts of nano silicon dioxide, 8 parts of aluminum trichloride.

[0075] In this embodiment, the volume ratio of the core layer and the skin layer is 1:2.85.

[0076] In this embodiment, the polyethylene is metallocene linear low density polyethylene.

[0077] In this embodiment, the aluminum trichloride is nano aluminum trich...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com