A kind of biomass polyester and polyamide blended fabric and its preparation method and product

A blended fabric and biomass technology, applied in the field of textile fabrics, can solve the problems of poor mechanical properties, moisture absorption, poor biodegradability, and poor wear resistance of biomass fabrics, and achieve good moisture absorption, good wear resistance, and durability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A biomass polyester and polyamide blended fabric, the biomass polyester and polyamide blended fabric is blended by biomass polyester composite fiber, polypentamethylene adipate fiber and polyhexamethylene lauramide fiber and obtained by knitting or weaving;

[0062] Among them, by weight: 55-65 parts of biomass polyester composite fiber, 30-37 parts of polypentamethylene adipate fiber and 14-18 parts of polyhexamethylene dodecanoyl diamide fiber;

[0063] The biomass polyester composite fiber is made from raw materials comprising the following parts by weight:

[0064] 30-70 parts of biomass succinate-pentanediol copolyester,

[0065] 35-70 parts of biomass furandic acid-hexanediol copolyester,

[0066] 4-7 parts of POSS modified carbon fiber;

[0067] The biomass succinate-pentanediol copolyester is formed by feeding bio-based succinic acid and bio-based 1,5-pentanediol according to a mass ratio of 1: (1.15-1.35), and polymerizing Made;

[0068] The biomass furan ...

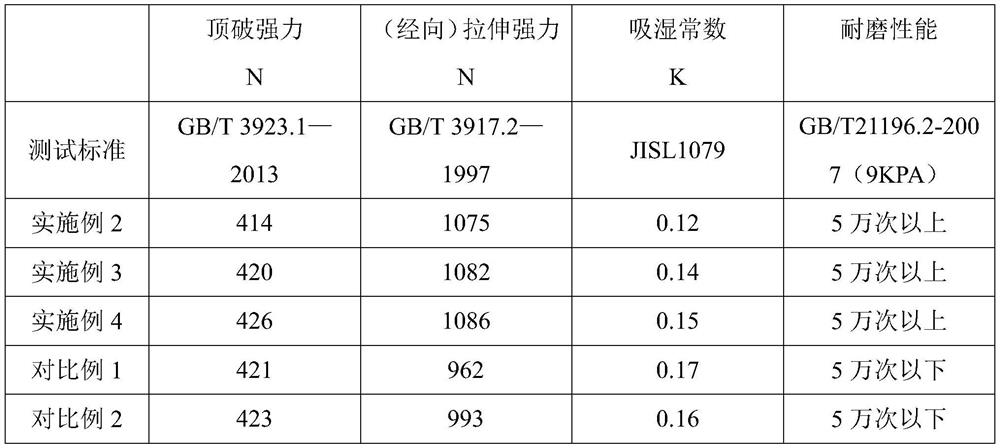

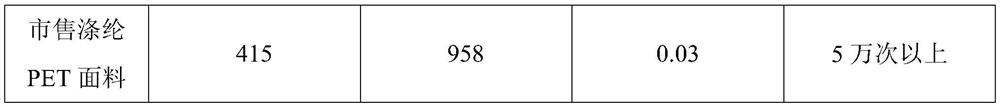

Embodiment 2

[0096] A biomass polyester and polyamide blended fabric, the biomass polyester and polyamide blended fabric is blended by biomass polyester composite fiber, polypentamethylene adipate fiber and polyhexamethylene lauramide fiber and obtained by knitting or weaving;

[0097] Wherein, in parts by weight: 55 parts of biomass polyester composite fiber, 30 parts of polypentamethylene adipate fiber and 14 parts of polyhexamethylene dodecanoamide fiber;

[0098] The biomass polyester composite fiber is made from raw materials comprising the following parts by weight:

[0099] 30 parts of biomass succinate-pentanediol copolyester,

[0100] 70 parts of biomass furandic acid-hexanediol copolyester,

[0101] 4 parts of POSS modified carbon fiber;

[0102] The biomass succinate-pentanediol copolyester is prepared by feeding bio-based succinic acid and bio-based 1,5-pentanediol according to a mass ratio of 1:1.15, and polymerizing;

[0103] The biomass furan dioic acid-hexanediol copoly...

Embodiment 3

[0124] A biomass polyester and polyamide blended fabric, the biomass polyester and polyamide blended fabric is blended by biomass polyester composite fiber, polypentamethylene adipate fiber and polyhexamethylene lauramide fiber and obtained by knitting or weaving;

[0125] Wherein, in parts by weight: 65 parts of biomass polyester composite fiber, 37 parts of polypentamethylene adipate fiber and 18 parts of polyhexamethylene dodecanoamide fiber;

[0126] The biomass polyester composite fiber is made from raw materials comprising the following parts by weight:

[0127] 70 parts of biomass succinate-pentanediol copolyester,

[0128] 35 parts of biomass furandic acid-hexanediol copolyester,

[0129] 7 parts of POSS modified carbon fiber;

[0130] The biomass succinate-pentanediol copolyester is prepared by feeding bio-based succinic acid and bio-based 1,5-pentanediol according to a mass ratio of 1:1.35, and polymerizing;

[0131] The biomass furandioic acid-hexanediol copolye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com