A Microfiber Polarization Coupler for Vector Stress Monitoring

A technology of stress monitoring and micro-optical fiber, which is applied in the field of sensing, can solve problems such as inaccurate target task requirements and inability to vectorize, and achieve high fatigue limit, good corrosion resistance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below through technical texts and drawings.

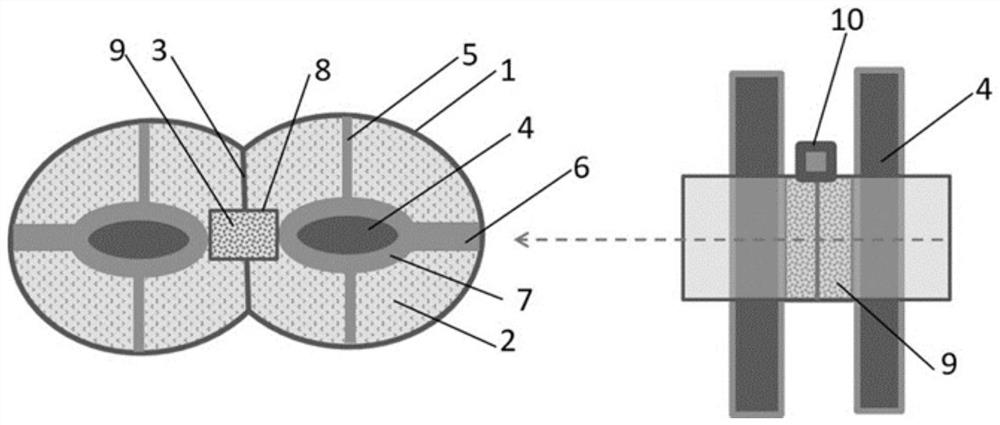

[0022] As shown in the figure, a micro-fiber polarization coupler for vector stress monitoring of the present invention has a main body consisting of a vertical stress rod 5, a horizontal stress rod 6, an elliptical micro-fiber 4, a rectangular hollow-core micro-fiber 8 and a CCD detector 10 coupled stress conduction monitoring structure; such as figure 1 , when the stress in the vertical direction acts, the stress is transmitted to the micro-fiber cladding 7 and the elliptical micro-fiber 4 through the vertical stress rod 5, causing them to deform; when the stress in the horizontal direction acts, the stress in the horizontal direction of the strain shell 1 is transmitted to The micro-fiber cladding 7 and the elliptical micro-fiber 4 enhance the internal light field of the rectangular hollow-core micro-fiber 8 and increase the visible light fluorescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com