Preparation method of citrus and Pu' er tea beverage

A production method, the technology of citrus tea, applied in the field of beverages, can solve the problems of price drop, sales lag, inventory backlog, etc., and achieve the effect of convenient drinking, mellow taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

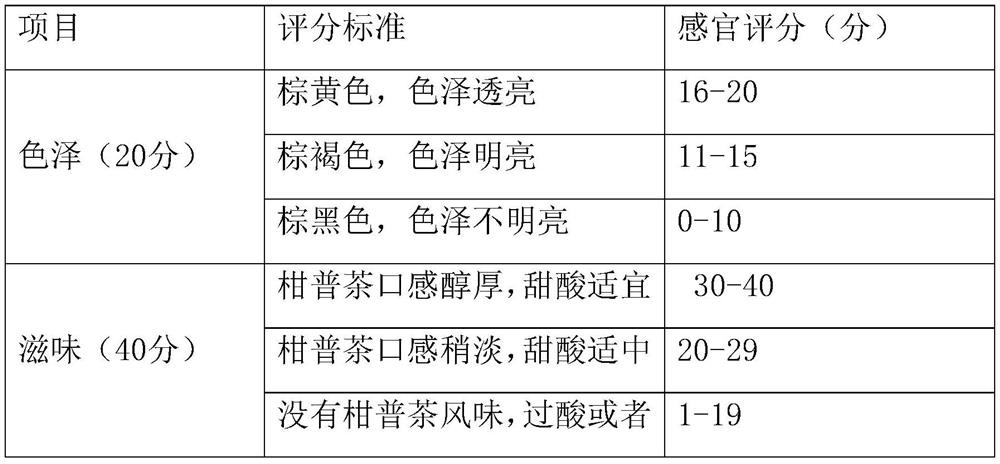

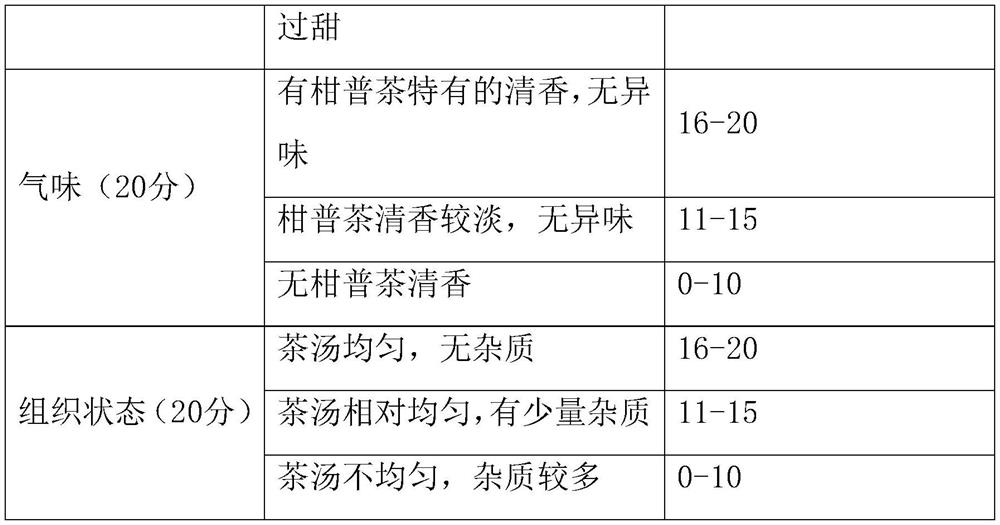

Examples

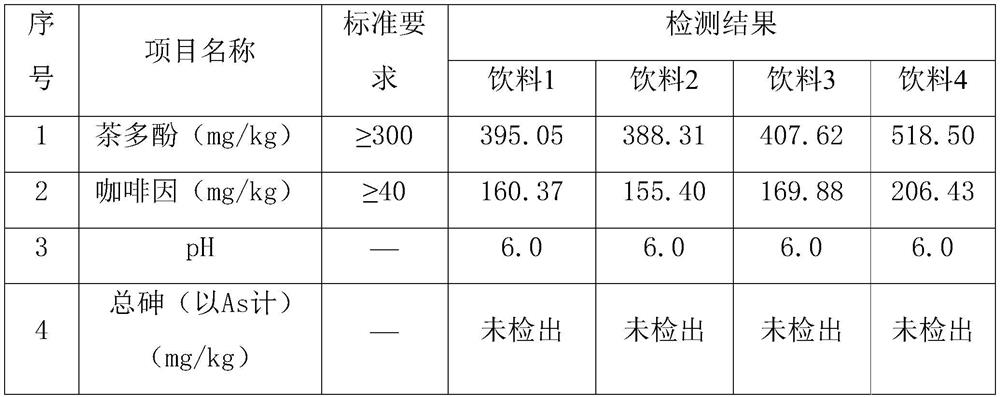

Embodiment 1

[0026] Weigh the citrus tea raw material, add water according to the mass ratio of tea and water as 1:80, adjust the pH value to 5 with citric acid, extract at 80°C for 30 minutes, first filter through 200 sieves, and then extract The liquid is rapidly cooled to 15°C, 7000r / min, centrifuged, and filtered to obtain a supernatant, add white sugar, vitamin C and sodium bicarbonate and other ingredients to make the pH reach 6, and finally sterilize at 135°C for 5 seconds, and then the tea liquid Cool to 75°C, bottle, sterilize after capping, and cool to below 38°C to become the finished beverage 1.

Embodiment 2

[0028] Weigh the citrus tea raw material, add water according to the mass ratio of tea and water in a ratio of 1:100, adjust the pH value to 5 with citric acid, extract at 70°C for 20 minutes, first filter through a 200 sieve, and then extract The liquid is rapidly cooled to 15°C, 7000r / min, centrifuged, and filtered to obtain a supernatant, add white sugar, vitamin C and sodium bicarbonate and other ingredients to make the pH reach 6, and finally sterilize at 135°C for 5 seconds, and then the tea liquid Cool to 75°C, bottle, sterilize after capping, and cool to below 38°C to become the finished beverage 2.

Embodiment 3

[0030] Weigh the citrus tea raw material, add water according to the mass ratio of tea and water as 1:60, adjust the pH value to 5 with citric acid, extract at 80°C for 25 minutes, first filter through 200 sieves, and then extract The liquid is rapidly cooled to 15°C, 7000r / min, centrifuged, and filtered to obtain a supernatant, which is added with ingredients such as white sugar, vitamin C, and sodium bicarbonate to make the pH reach 6, and finally sterilized at 138°C for 5 seconds, and then the tea liquid Cool to 80°C, bottle, sterilize after capping, and cool to below 38°C to become the finished beverage 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com