Method for pre-separating cyperus esculentus peel layer

A technology for the skin layer and pre-separation of oil bean bean, which is applied in the fields of vegetable or fruit peeling, food science, and application, can solve the problems of incomplete peeling, low efficiency, waste, etc. Simple operation and less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

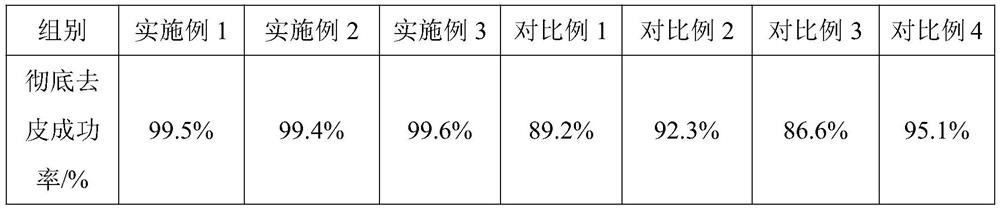

Embodiment 1

[0027] The pre-separation of oily bean skin layer comprises the following steps:

[0028] (1) Pre-treatment of machine harvested fresh oil and beans

[0029] Machine-collected fresh oil beans are selected to remove the spoiled parts such as mildew and corruption, double-action high-pressure water spray cleaning, draining, and negative pressure continuous microwave drying at a temperature of 45°C and a pressure of -0.08MPa to moisture The content is 10%, save it for later use;

[0030] (2) Rapid pre-separation of the skin layer of Yousha bean

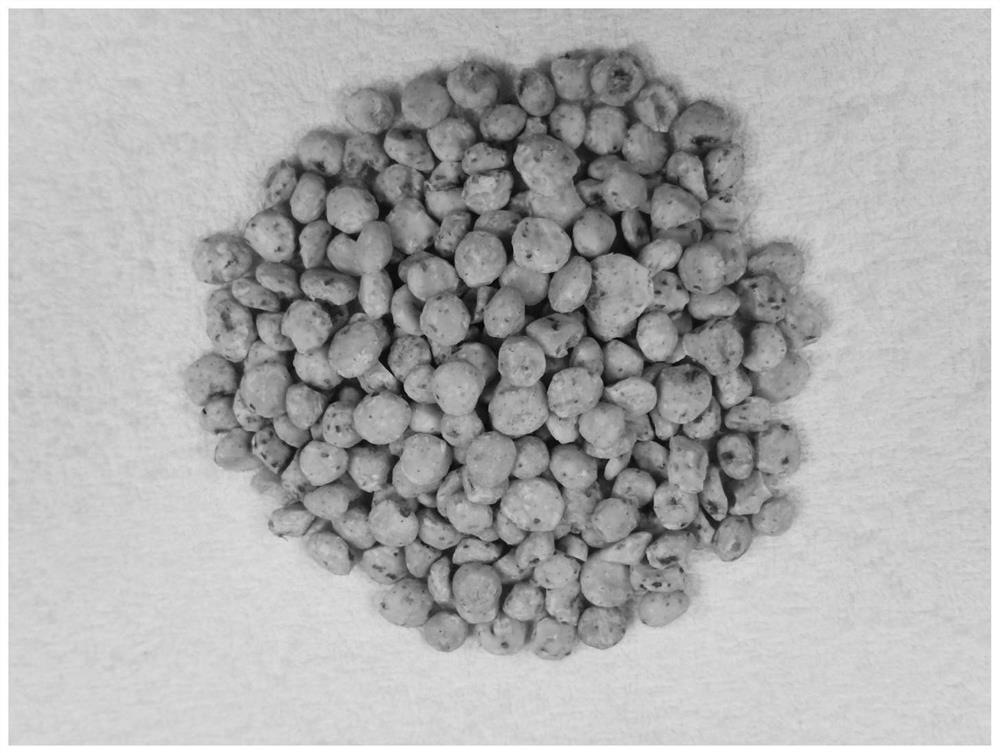

[0031] Put the oily bean processed in step (1) into an electromagnetic oscillation environment for cortex pre-separation treatment. The electromagnetic oscillation temperature is 35°C, the electromagnetic oscillation frequency is 2500MHz, and the electromagnetic oscillation treatment time is 10min. After cooling, observe its appearance and find that The tight structure between bean skin and bean meat becomes loose, such as figure 1 As...

Embodiment 2

[0034] The pre-separation of the oily bean skin layer, the steps are as follows:

[0035] (1) Pre-treatment of machine harvested fresh oil and beans

[0036] Machine-collected fresh oil and beans are selected to remove the spoiled parts such as mildew and corruption, double-action high-pressure water spray cleaning, draining water, and negative pressure continuous microwave drying at a temperature of 55°C and a pressure of -0.08MPa to moisture The content is 8%, save it for later use;

[0037] (2) Rapid pre-separation of the skin layer of Yousha bean

[0038] Put the oily beans processed in step (1) into an electromagnetic oscillation environment for cortex pre-separation treatment. The electromagnetic oscillation temperature is 45°C, the electromagnetic oscillation frequency is 2400MHz, the electromagnetic oscillation treatment time is 13min, and cooled to obtain a complete pre-separation of the cortex. Yousha beans, at this time, the looseness between the bean skin and the...

Embodiment 3

[0040] The pre-separation of oily bean skin layer comprises the following steps:

[0041] (1) Pre-treatment of machine harvested fresh oil and beans

[0042] Machine-collected fresh oil and beans are selected to remove the spoiled parts such as mildew and corruption, double-acting high-pressure water spray cleaning, draining water, and negative pressure continuous microwave drying at a temperature of 50°C and a pressure of -0.08MPa to moisture The content is 9%, save it for future use;

[0043] (2) Rapid pre-separation of the skin layer of Yousha bean

[0044] Put the oily beans processed in step (1) into an electromagnetic oscillation environment for pre-separation of the cortex. The electromagnetic oscillation temperature is 40°C, the electromagnetic oscillation frequency is 2450MHz, and the electromagnetic oscillation treatment time is 12 minutes. After cooling, the cortex is completely pre-separated. Yousha beans, at this time, the looseness between the bean skin and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com