Method for treating copper-containing printing ink wastewater

A technology of ink wastewater and treatment methods, applied in the field of industrial sewage, can solve the problems of high cost, no recycling value, high copper ion content, etc., and achieve the effect of low cost and high recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

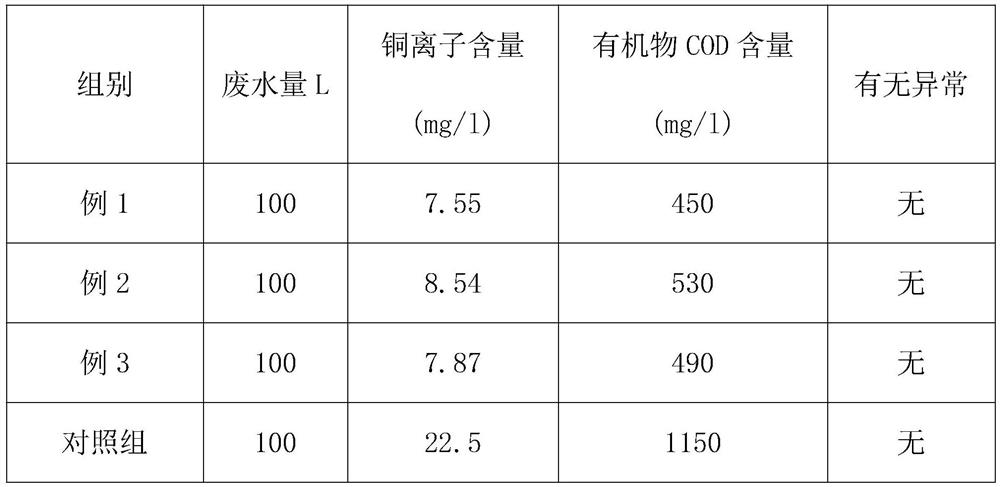

Examples

Embodiment 1

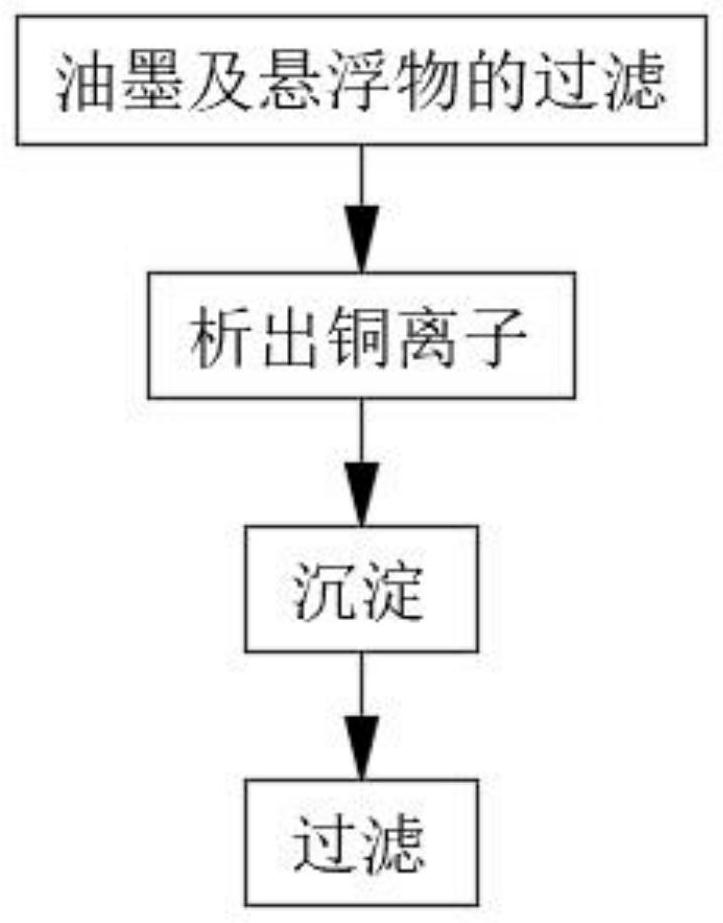

[0025] The treatment method of this copper-containing ink wastewater comprises the steps:

[0026] S1: Filtration of ink and suspended solids: pump the pretreated copper-containing ink wastewater from the storage tank to the acidification tank at a flow rate of 150L / H, add acid until the pH is 2.5 and stir, and then stay for 30 minutes after stirring evenly, after acidification After the copper-containing ink wastewater, most of the ink and suspended matter will float on the surface. After filtering, the ink and suspended matter floating on the surface will be filtered out. Only a small part of the ink and copper-containing ink dissolved in the wastewater will be present in the wastewater. waste water;

[0027] S2: Precipitation of copper ions: the filtered pretreated wastewater is pumped into a sedimentation tank with a volume of 2 cubic meters according to the flow rate of 150L / H, and ferrous sulfate powder is added to the sedimentation tank according to the ratio of 1 kg / cu...

Embodiment 2

[0031] The treatment method of this copper-containing ink wastewater comprises the steps:

[0032] S1: Filtration of ink and suspended solids: pump the pretreated copper-containing ink wastewater from the storage tank to the acidification tank at a flow rate of 170L / H, add acid until the pH is at 2, stir, and stay for 20 minutes after stirring evenly, after acidification After the copper-containing ink wastewater, most of the ink and suspended matter will float on the surface. After filtering, the ink and suspended matter floating on the surface will be filtered out. Only a small part of the ink and copper-containing ink dissolved in the wastewater will be present in the wastewater. waste water;

[0033]S2: Precipitation of copper ions: the filtered pretreated wastewater is pumped into a sedimentation tank with a volume of 2 cubic meters according to the flow rate of 170L / H, and ferrous sulfate powder is added to the sedimentation tank according to the ratio of 0.8 kg / cubic wa...

Embodiment 3

[0037] The treatment method of this copper-containing ink wastewater comprises the steps:

[0038] S1: Filtration of ink and suspended solids: pump the pretreated copper-containing ink wastewater from the storage tank to the acidification tank at a flow rate of 200L / H, add acid until the PH is at 3 and stir, stir evenly and stay for 30 minutes, after acidification After the copper-containing ink wastewater, most of the ink and suspended matter will float on the surface. After filtering, the ink and suspended matter floating on the surface will be filtered out. Only a small part of the ink and copper-containing ink dissolved in the wastewater will be present in the wastewater. waste water;

[0039] S2: Precipitation of copper ions: the filtered pretreated wastewater is pumped into a sedimentation tank with a volume of 2 cubic meters according to the flow rate of 200L / H, and ferrous sulfate powder is added to the sedimentation tank according to the ratio of 1.2 kg / cubic wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com