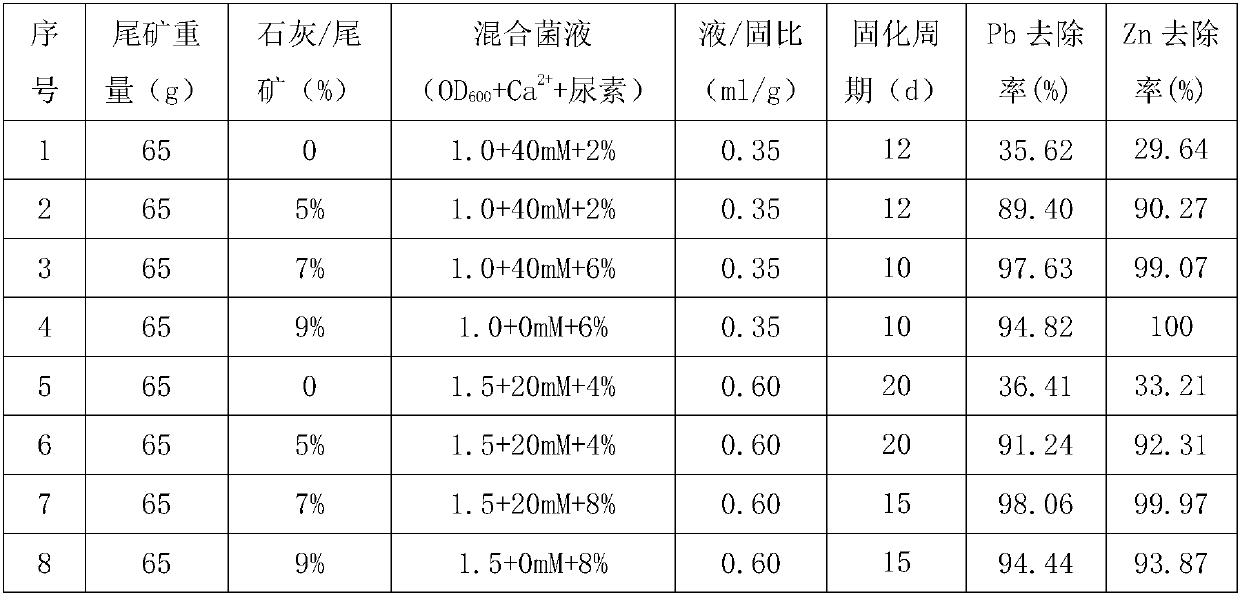

Patents

Literature

30 results about "Ionic copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ionic Copper is an all natural mineral supplement in the form of ionic copper ions of 0.9999 pure copper in pure deionized water. Gallon size jugs save 42% vs. the single bottle price.

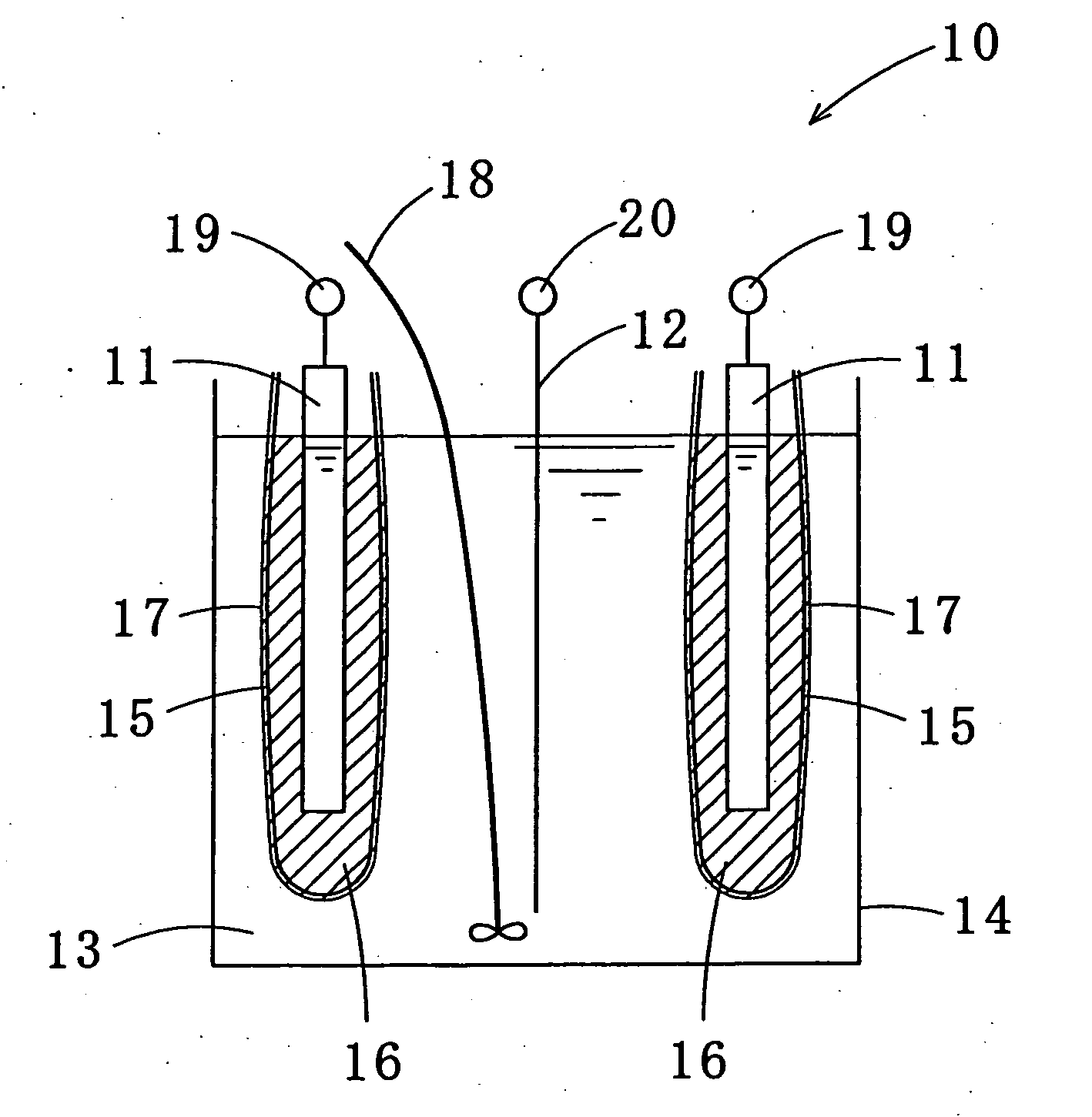

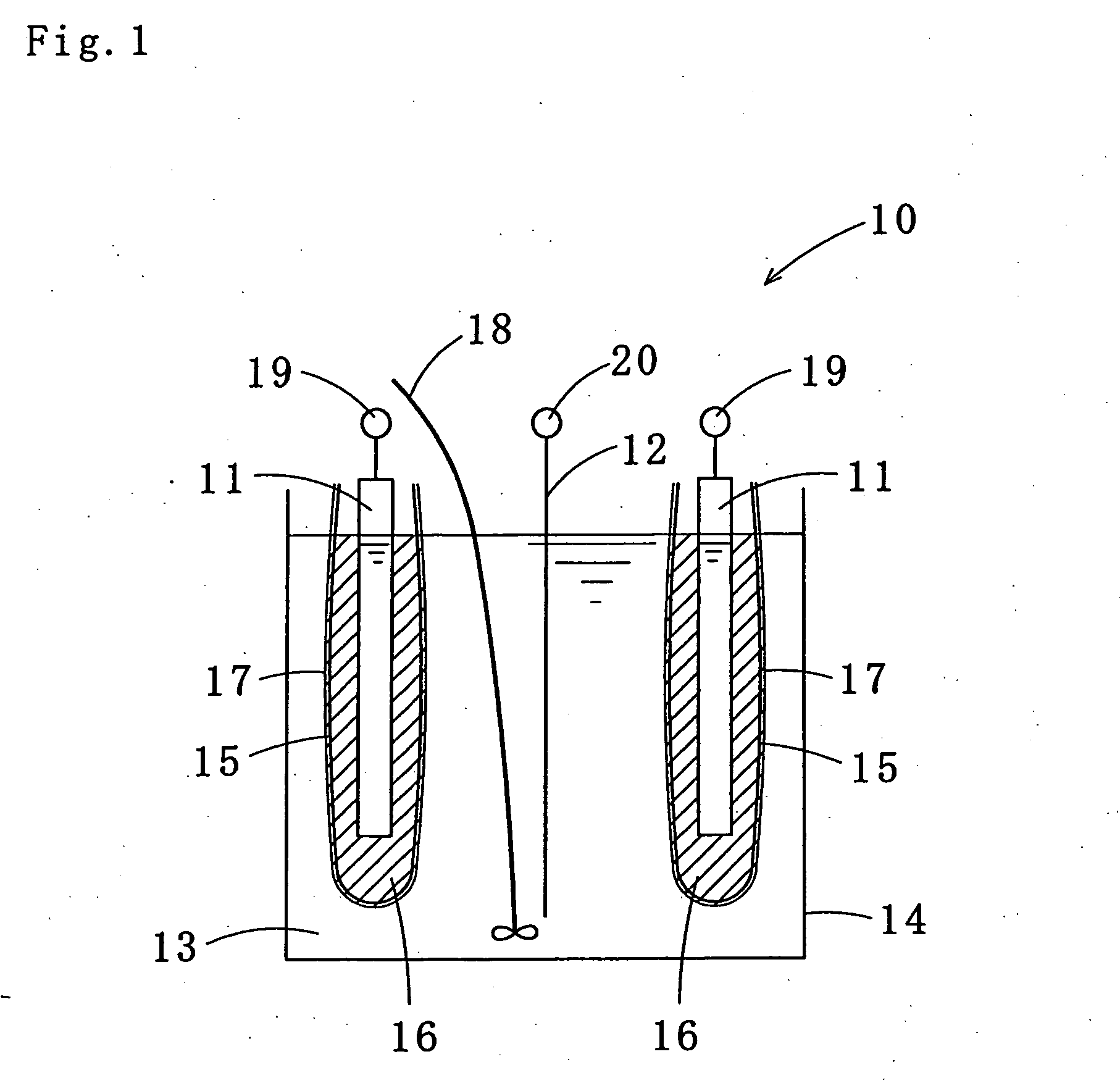

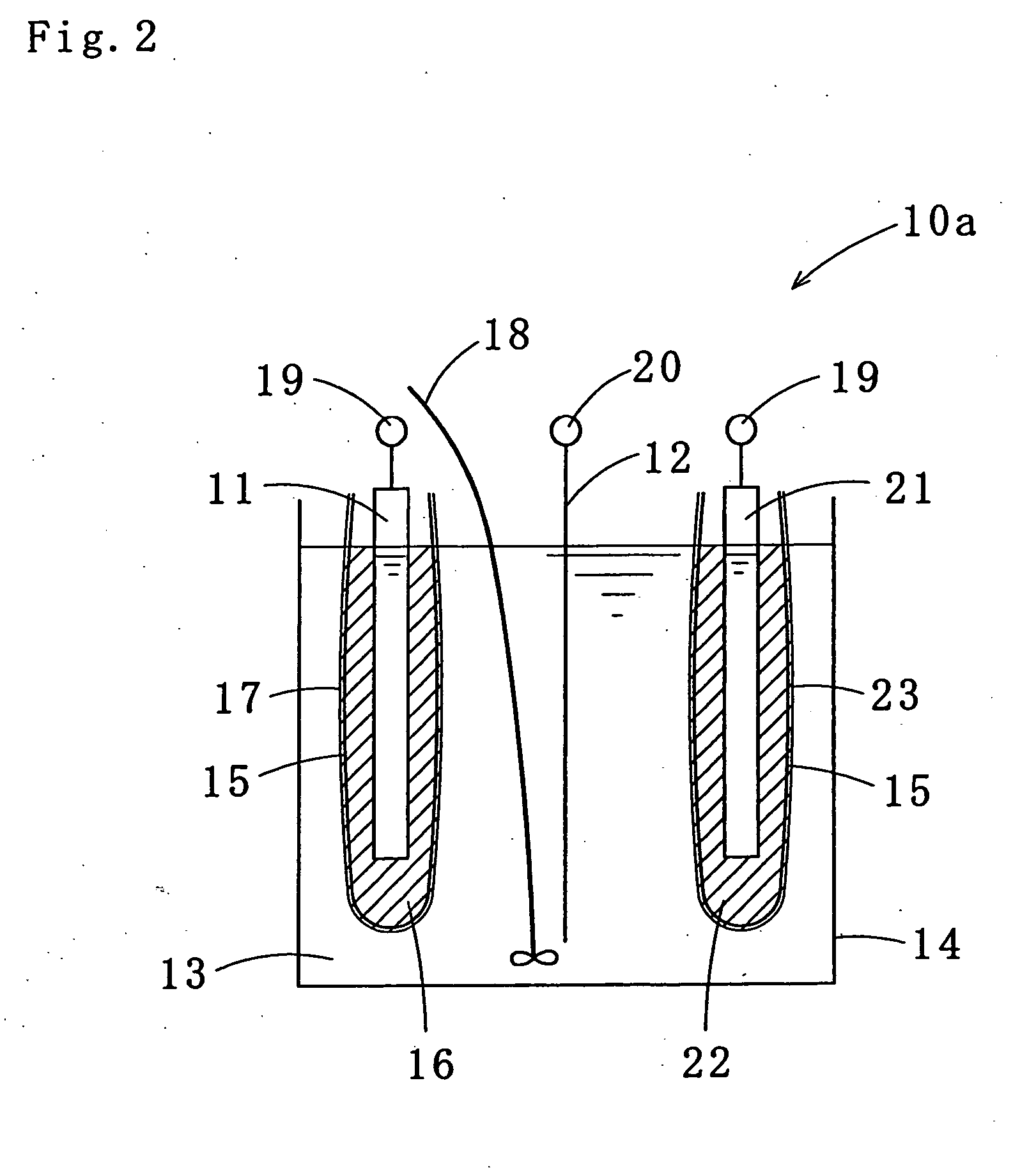

Tin-silver-copper plating solution, plating film containing the same, and method for forming the plating film

InactiveUS20050184369A1High joining strengthLow heating temperatureCellsPrinted circuit assemblingTin-silver-copperCopper

A tin-silver-copper contains plating solution which comprises water which is a primary medium, a sulfonic acid, a tin ion, a copper ion and a silver ion, wherein concentrations of the silver ion, the tin ion and the copper ion are 0.0015 to 0.1 mol / L, 0.21 to 2 mol / L and 0.002 to 0.02 mol / L, respectively; a plating film which has 2.6 to 3.4 weight percent of silver, 0.4 to 0.7 weight percent of copper and the substantially balanced amount of tin; an electrolytic plating method for use in forming the above plating film from the above plating solution; and a soldering method using the plating film.

Owner:SHINRYOI CORP

Copper (1) compound with imidazole derivate as compounding body

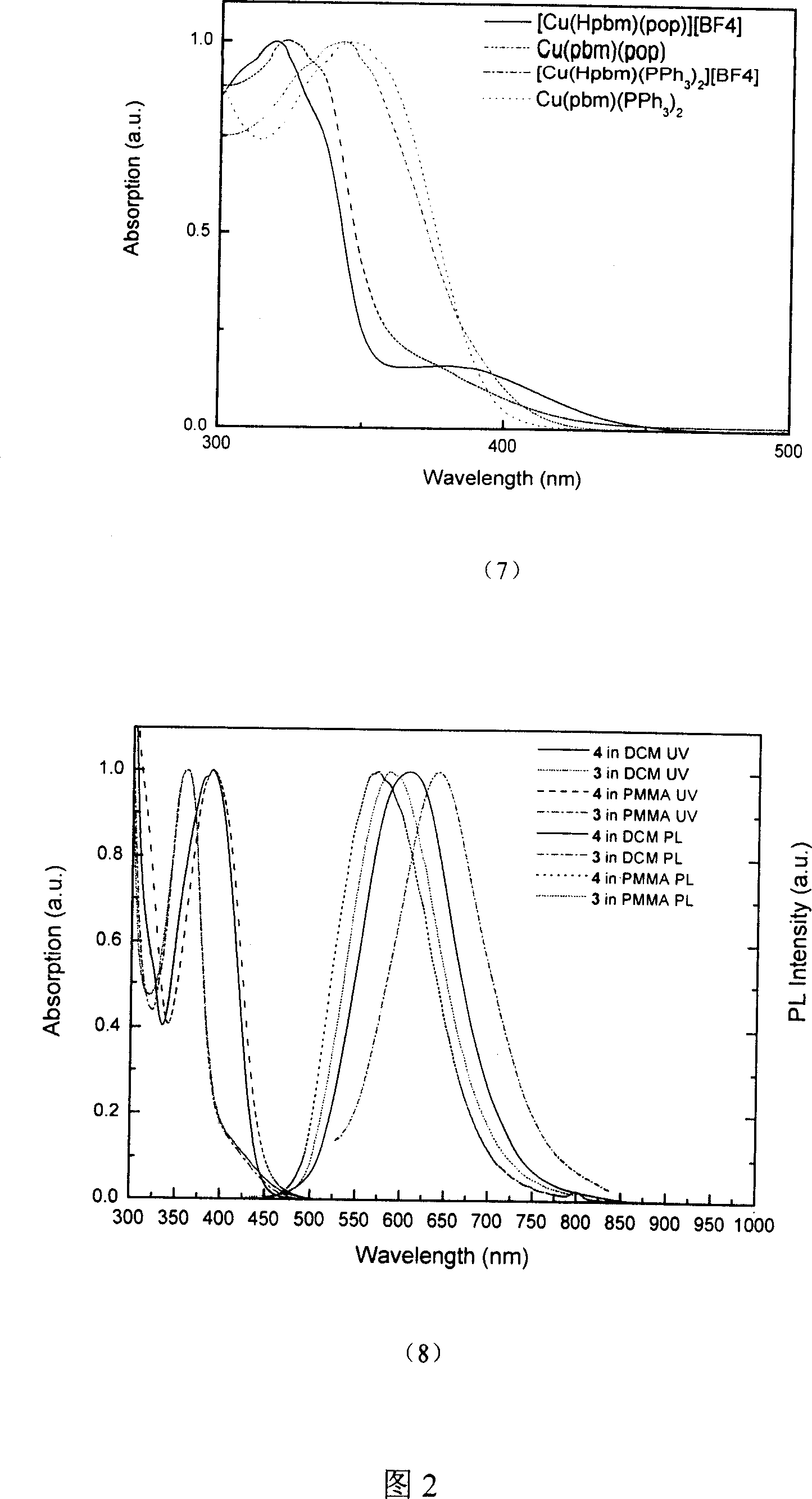

InactiveCN100999528AEasy to synthesizeEasy to purifyCopper organic compoundsLuminescent compositionsRoom temperatureTriphenylphosphine

The present invention relates to copper complex with imidazole as ligand. Ionic one-valent copper complex is prepared with pyridyl imidazole, pyridyl benzimidazole or quinolyl benzimidazole as the first ligand, triphenyl phosphine or bridged phenyl phosphine as the second ligand and one-valent copper ion. Neutral copper complex may be further obtained under the action of alkali. The ionic copper complex and the neutral copper complex may convert mutually under the action of acid and alkali. This kind of complex possesses strong room temperature phosphorescence emission and may be used as light emitting material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

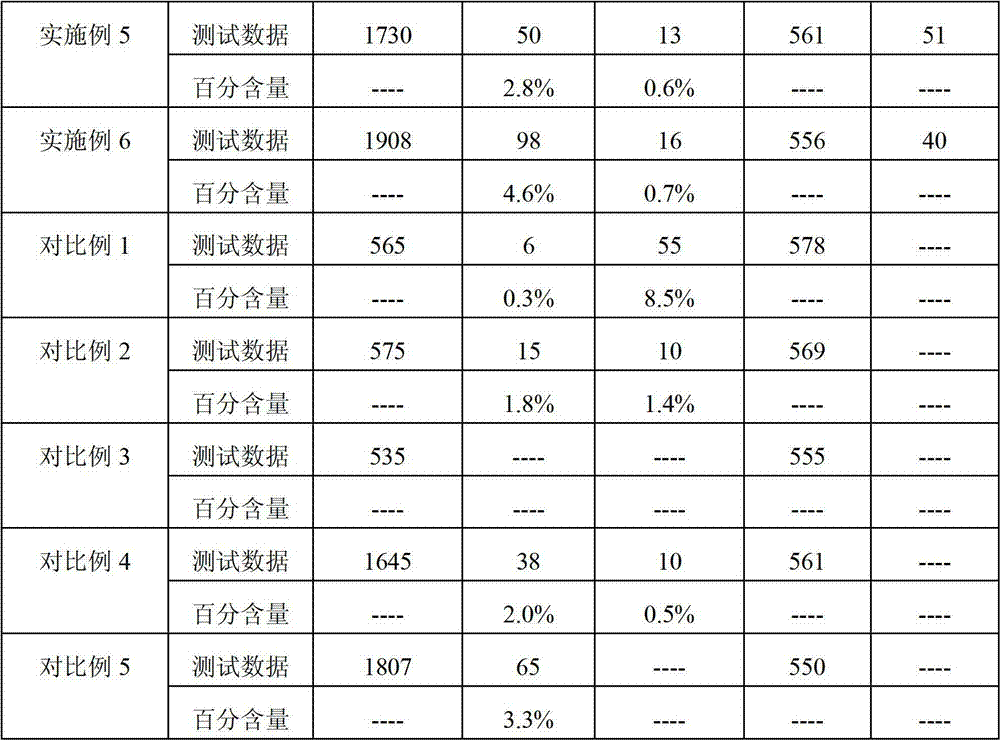

Cyanide-free zinc dipping solution and cyanide-free electroplating method of filter aluminium alloy by using the same

The invention discloses a cyanide-free zinc dipping solution and a cyanide-free electroplating method of filter aluminium alloy by using the cyanide-free zinc dipping solution. The cyanide-free zinc dipping solution, measured as per liter of cyanide-free zinc dipping solution, comprises 450-600 ml of plating bath solution and 400-550 ml of water, wherein the plating bath solution comprises 20-40 g / L zinc ions, 2-10 g / L nickel ions, 0.001-0.400 g / L copper ions, 0.05-1.00 g / L iron ions, 1-4 g / L cobalt ions, 80-200 g / L alkali metal hydroxide, 50-100 g / L main complexing agent, 13-40 g / L auxiliary complexing agent, and 0.07-2.00 g / L crystallization refiner. Zinc dipping and electroplating on materials with high silica content can be carried out by using the cyanide-free zinc dipping solution by just conducting zinc dipping once, the operation is simple, and the control is easy.

Owner:GUANGZHOU HONWAY TECH CORP +1

Defect reduction in electrodeposited copper for semiconductor applications

InactiveUS7316772B2Improve surface morphologyFew defectSemiconductor/solid-state device manufacturingPrinted circuit manufactureWaferingMetallurgy

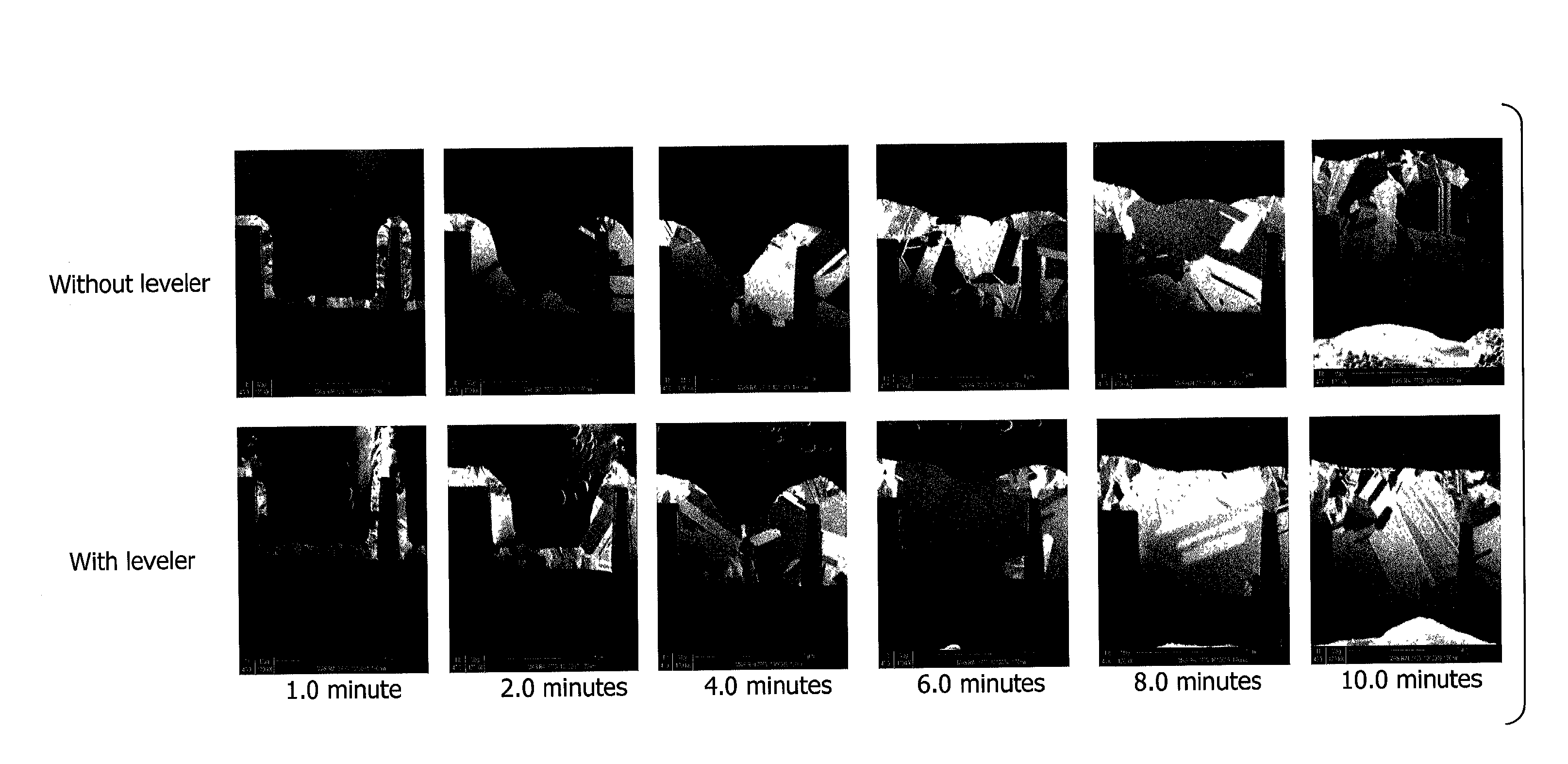

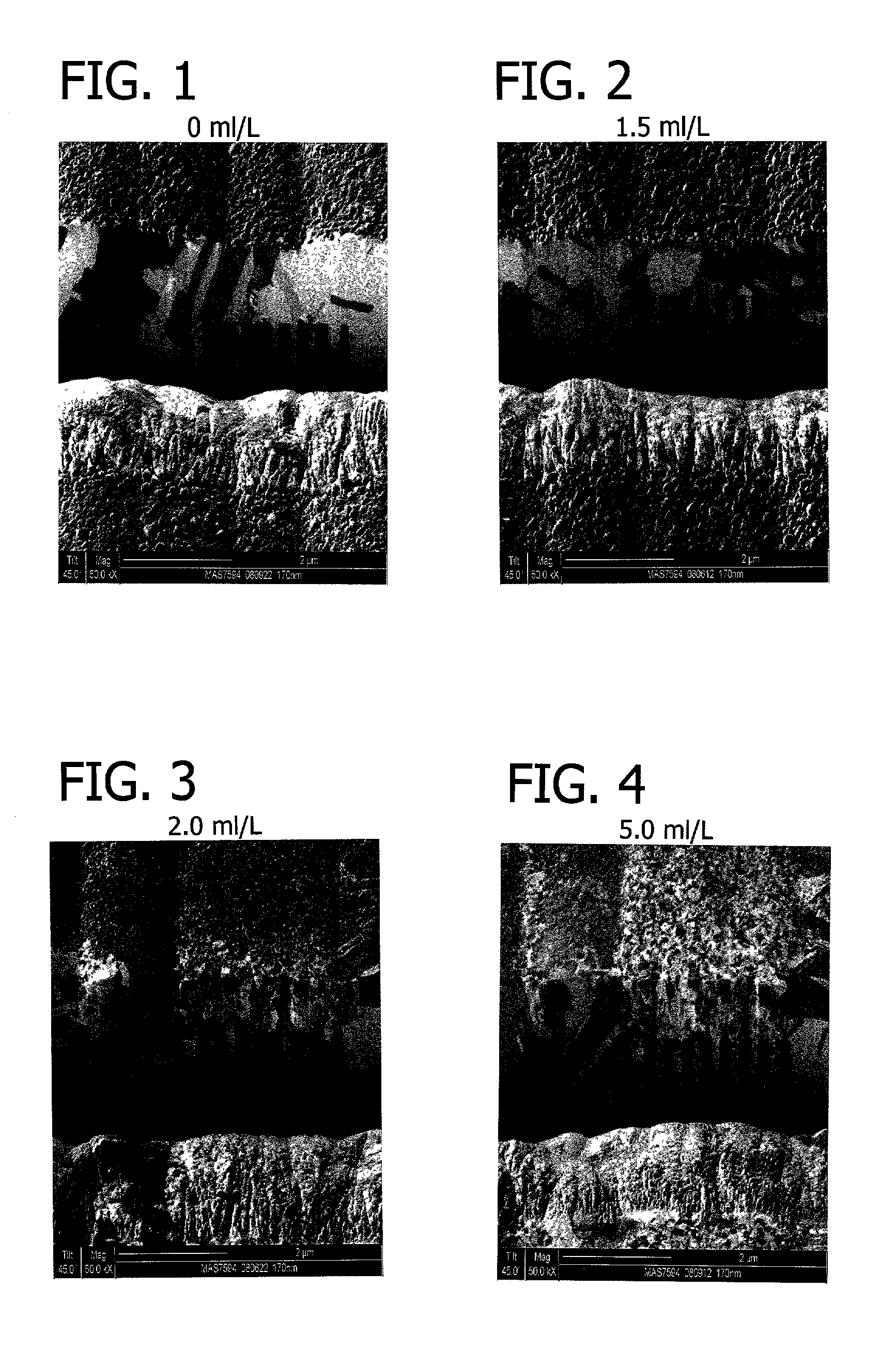

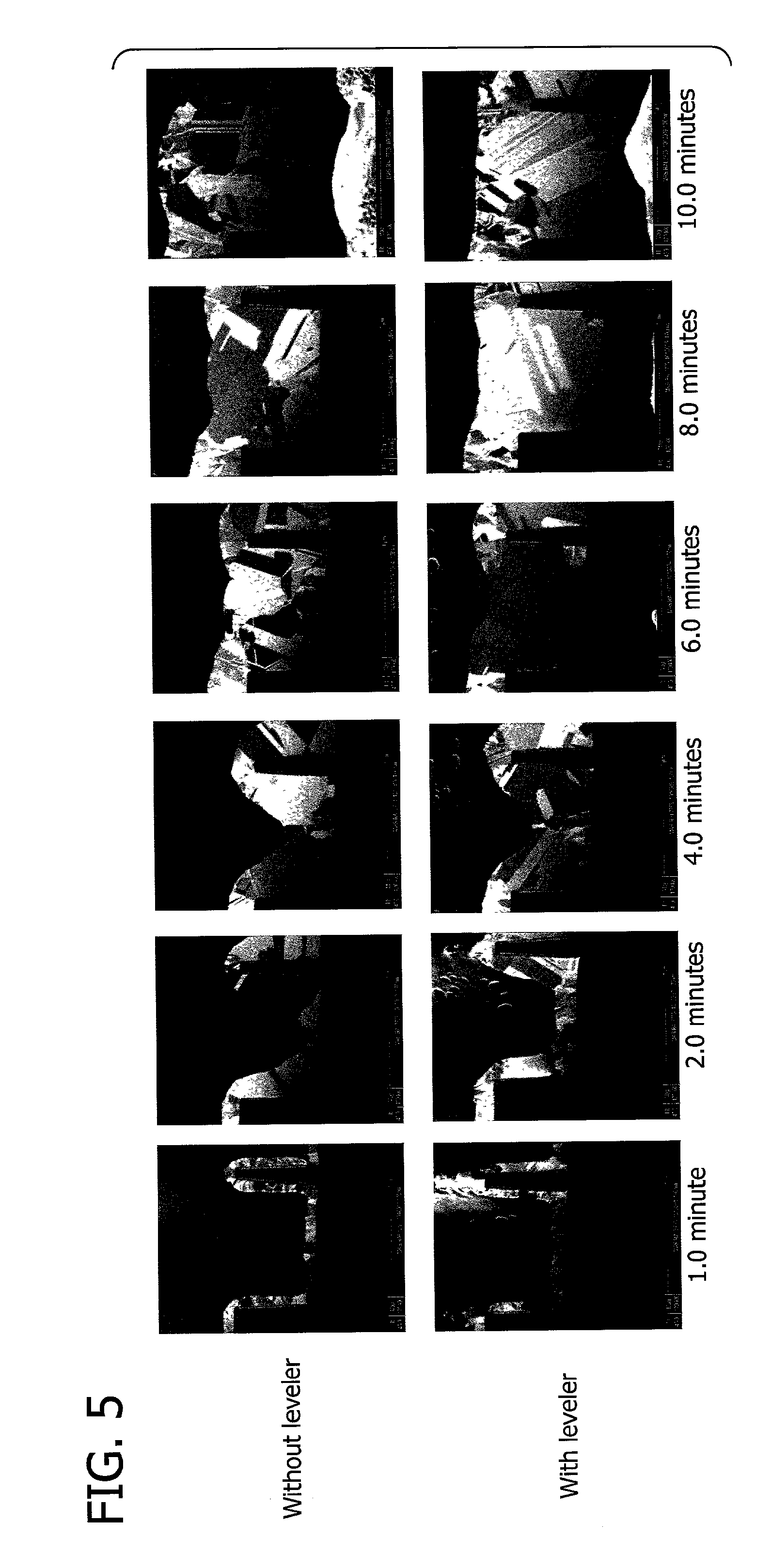

A method for electroplating a copper deposit onto a semiconductor integrated circuit device substrate having submicron-sized features, and a concentrate for forming a corresponding electroplating bath. A substrate is immersed into an electroplating bath formed from the concentrate including ionic copper and an effective amount of a defect reducing agent, and electroplating the copper deposit from the bath onto the substrate to fill the submicron-sized reliefs. The occurrence of protrusion defects from superfilling, surface roughness, and voiding due to uneven growth are reduced, and macro-scale planarity across the wafer is improved.

Owner:MACDERMID ENTHONE INC

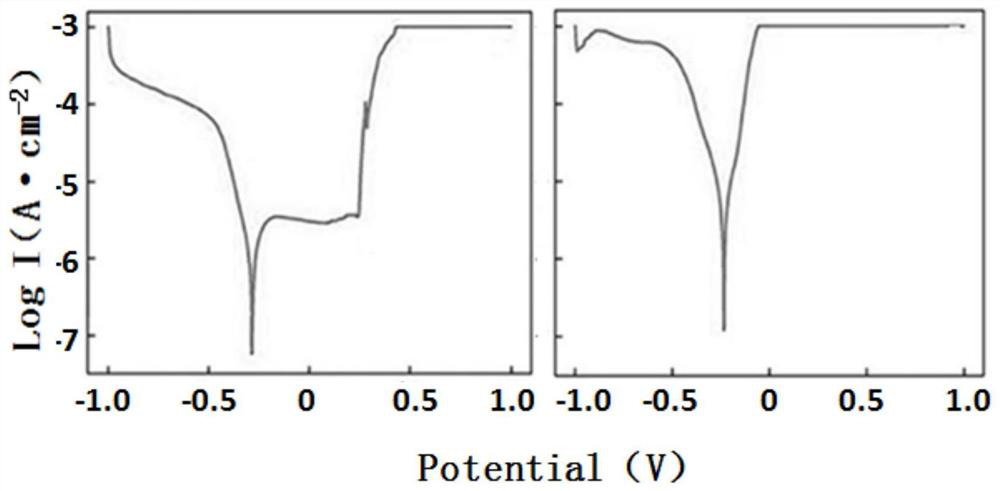

Site fast detection method for copper, zinc, lead and cadmium as heavy metals in seawater

ActiveCN102798657AReduce usageDoes not affect normal useMaterial electrochemical variablesSquare wave anodic stripping voltammetryCadmium Cation

The invention discloses a site fast detection method for copper, zinc, lead and cadmium as heavy metals in seawater, and belongs to the technical field of environment monitoring. A conducting carbon black-ionic liquid paste electrode as a work electrode, Ag / AgCl as a reference electrode and platinum filament or glass carbon as a counter electrode are assembled to form an electrochemical sensor. The concentrations of ionic copper, zinc, lead and cadmium in seawater are respectively determined by adopting square wave anodic stripping voltammetry; and the site fast detection method has the advantages of high sensitivity, favorable repeatability, simple and convenient operation, low expense, quick response, accurate quantification, low requirement on the environment condition and the like, and can be used for site monitoring of offshore pollution and conventional ocean site investigation along with ships.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

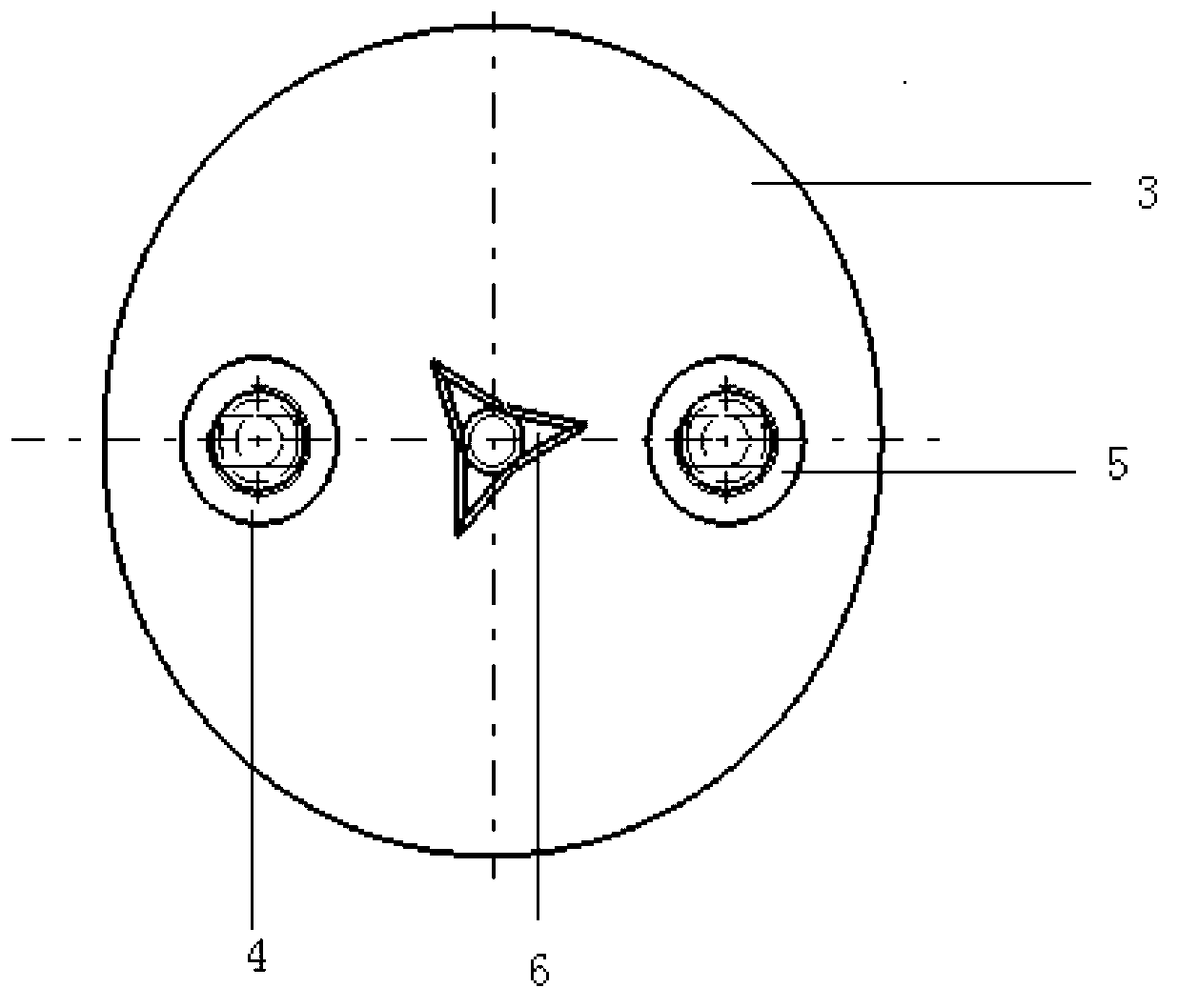

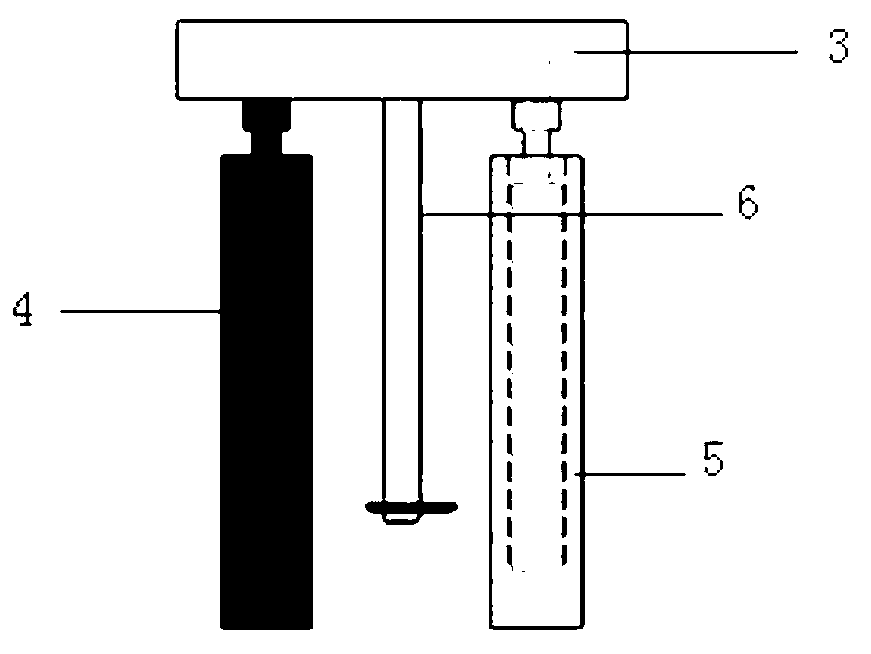

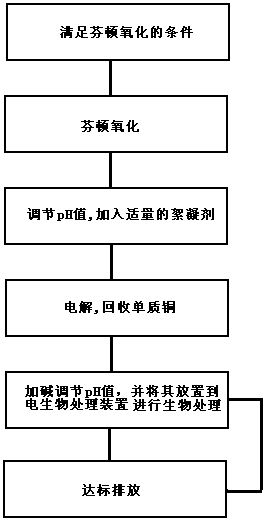

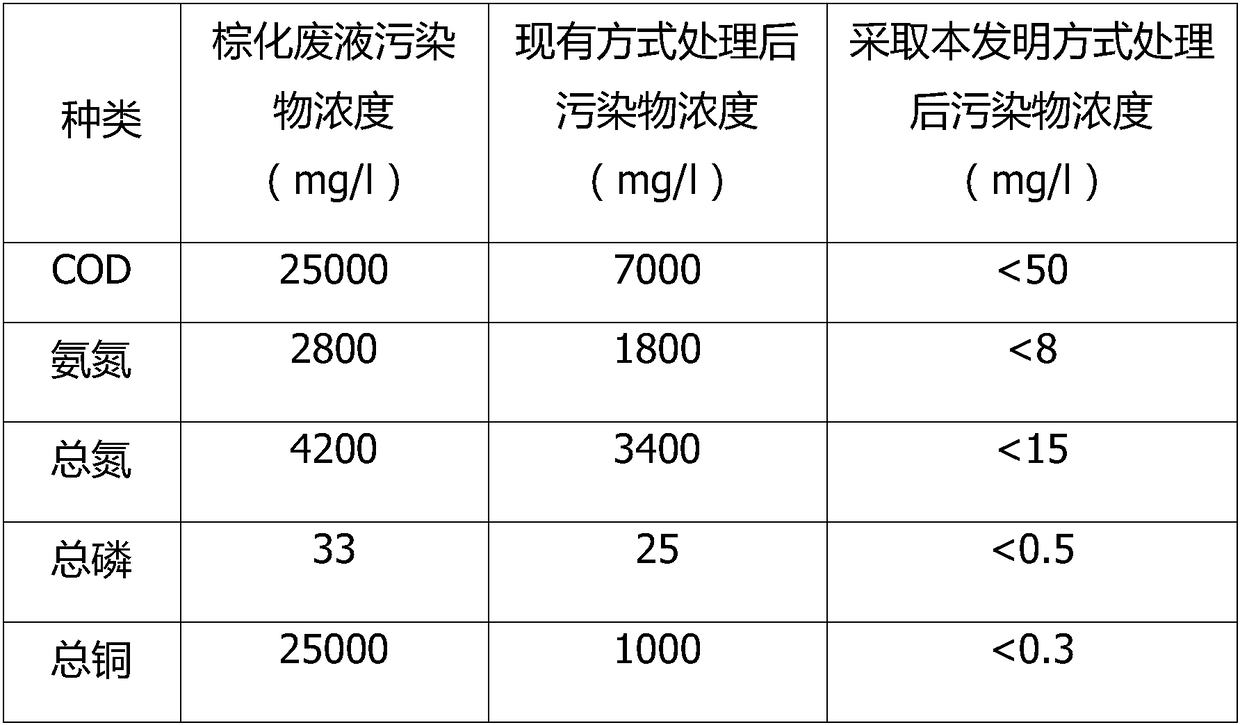

Treatment technology of browned waste liquid produced by PCB (Printed Circuit Board)

InactiveCN108249704AReduce pollutant indexIngenious processPhotography auxillary processesTreatment using aerobic processesChemical treatmentLiquid waste

The invention discloses a treatment technology of browned waste liquid produced by PCB (Printed Circuit Board). Through chemical treatment, complex copper in the browned waste liquid can be convertedinto ionic copper; by adopting an electrolytic treatment mode, valuable elementary copper in the browned waste liquid can be extracted; by adopting a biological treatment mode, great reduction of indexes of all pollutants in the browned waste liquid is realized, up-to-standard emission of the browned waste liquid produced by the PCB can be realized, a process is ingenious, the operation is convenient, and a good application prospect is obtained.

Owner:WUXI SHENNAN CIRCUITS CO LTD

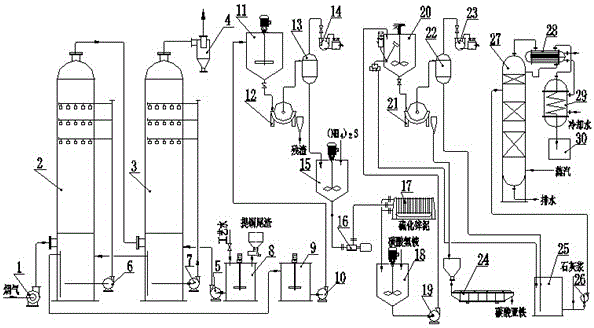

Method and device for removing SO2 in flue gas with copper extracting tailings and recycling copper extracting tailings

ActiveCN106422716AWith spray densityIncrease contact areaGas treatmentDispersed particle separationMetasilicateAmmonium sulfide

The invention relates to a method and device for removing SO2 in flue gas with copper extracting tailings and recycling the copper extracting tailings, and belongs to the technical field of environmental protection. Ferrous metasilicate (Fe2SiO4), magnesium ferrite (MgFe2O4), hedenbergite (CaFeSi2O6) and other sulfur removal active substances in the copper extracting tailings are used for reacting with SO2 in the flue gas in an aqueous solution to generate sulfite, then sulfate is generated under the action of oxygen in the flue gas, the SO2-containing flue gas makes contact with copper extracting tailing slurry, SO2 is absorbed, and thus the flue gas is purified; by adding ammonium sulfide, ammonium bicarbonate and lime milk step by step, iron ions, zinc ions, copper ions, ammonium ions and other ions in the sulfur removal slurry can be resourcelized to be reused.

Owner:KUNMING UNIV OF SCI & TECH

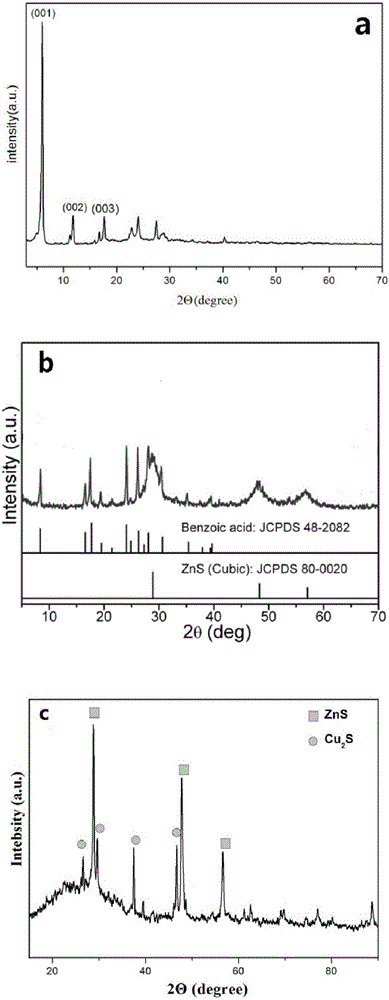

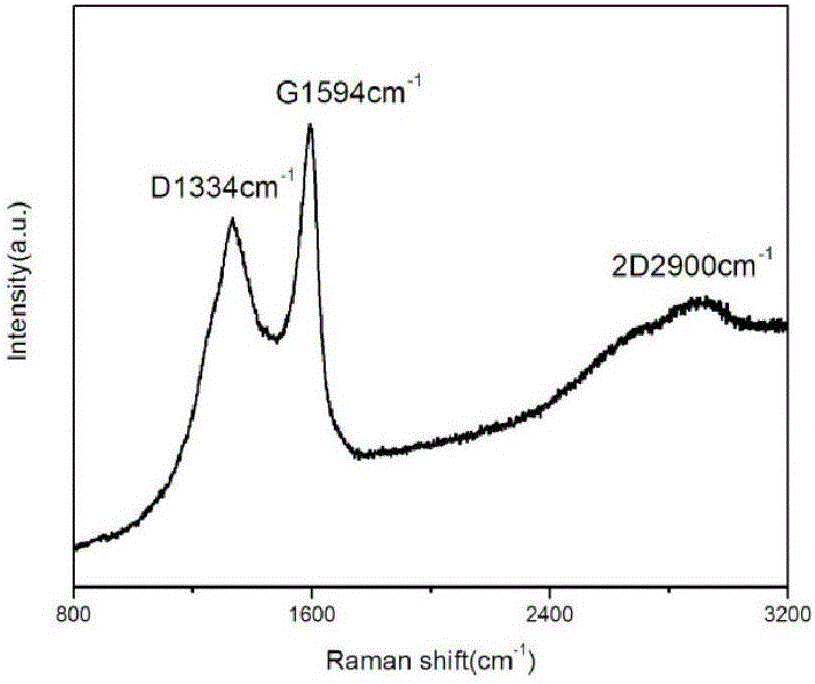

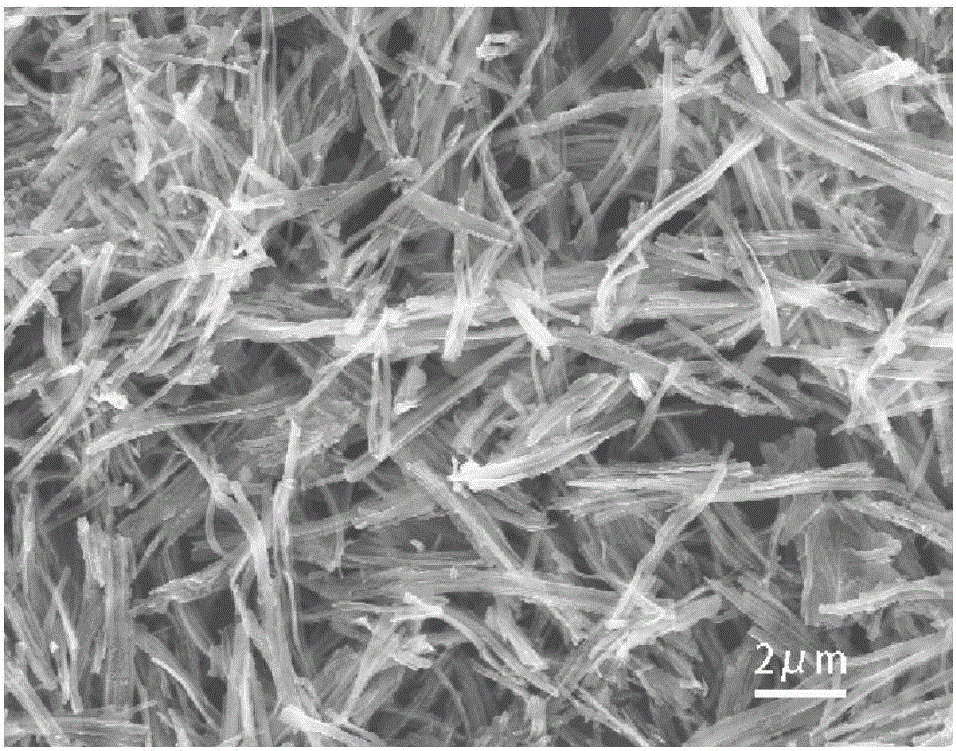

Zinc-sulfide, cuprous-sulfide and carbon nanocomposite and preparing method thereof

The invention discloses a one-dimensional zinc-sulfide, cuprous-sulfide and carbon nanocomposite and a preparing method thereof. The preparing method includes the steps that zinc salt, copper salt and benzoate serve as raw materials, the coordination of zinc ions, copper ions and carboxyl functional groups of benzoic acid radicals is adopted, self assembling is carried out in an aqueous phase solution, and a benzoic-acid-radical-intercalation layered zinc-hydroxide-copper nanocomposite is obtained; then the benzoic-acid-radical-intercalation layered zinc-hydroxide-copper nanocomposite is reacted with hydrogen sulfide, the product is roasted in nitrogen, and the zinc-sulfide, cuprous-sulfide and carbon nanocomposite is prepared. According to the zinc-sulfide, cuprous-sulfide and carbon nanocomposite and the preparing method, the preparing technology is simple, sources of raw materials are rich, production is easy to enlarge, and compounding of cuprous sulfide, zinc sulfide and carbon nanomaterials and effective regulating and control of the size and the dispersity of cuprous sulfide nano particles are achieved with a solid-state pyrolysis method.

Owner:BEIJING UNIV OF CHEM TECH

Method of leaching copper and gold from sulfide ores

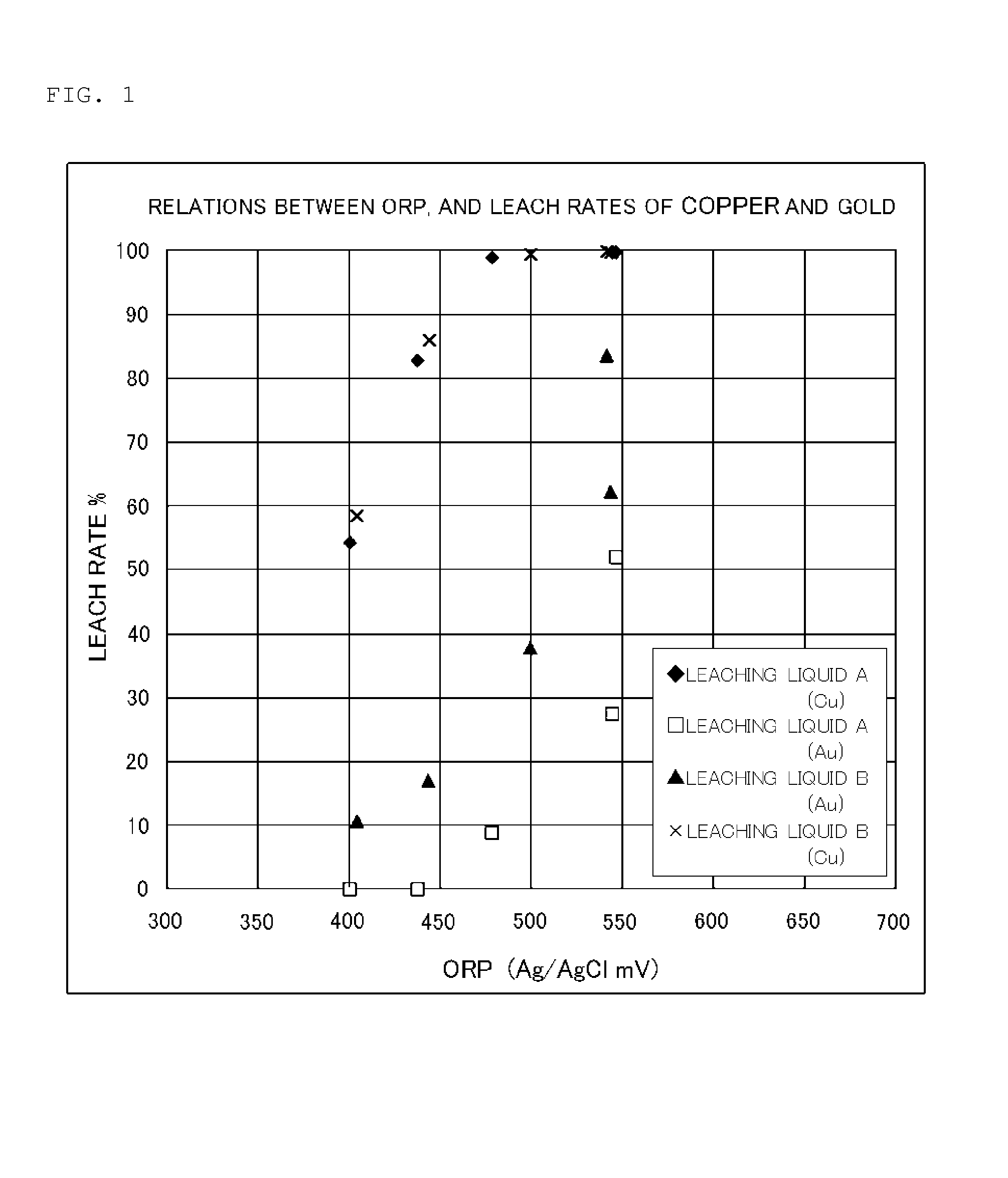

ActiveUS20120222519A1Improve efficiencyRecovery yieldRecycling and recovery technologiesProcess efficiency improvementPregnant leach solutionBromine

Disclosed is a method of leaching copper and gold from sulfide ores, which includes Process (1) of bringing a first aqueous acidic solution which contains chlorine ion, copper ion and iron ion, but no bromine ion, into contact with sulfide ores under supply of an oxidizing agent, so as to leach copper component contained in the sulfide ores; Process (2) of separating, by solid-liquid separation, a leaching reaction liquid obtained in Process (1), into a leaching residue and a leachate; and Process (3) of bringing a second aqueous acidic solution which contains chlorine ion, bromine ion, copper ion and iron ion, into contact with the leaching residue obtained in Process (2) under supply of an oxidizing agent, so as to leach gold contained in the leaching residue.

Owner:JX NIPPON MINING& METALS CORP

Hydrogen peroxide disinfectant and preparation method thereof

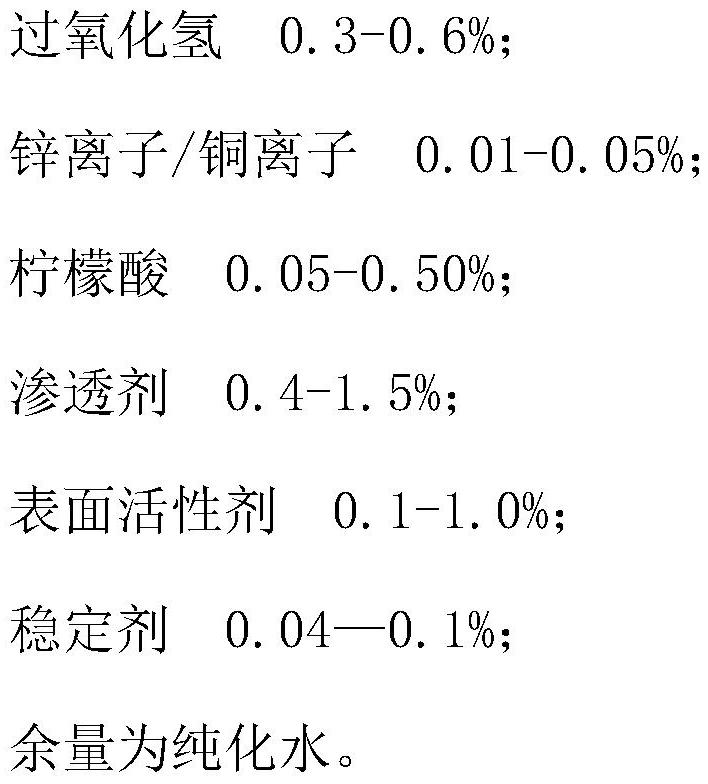

InactiveCN112514913AEnhanced inhibitory effectAvoid decompositionBiocideFungicidesOtic AgentsActive agent

The invention discloses a hydrogen peroxide disinfectant. Thehydrogen peroxide disinfectantis composed of the following components in percentage by weight: 0.3-0.6% of hydrogen peroxide, 0.01%-0.05% of zinc ions / copper ions, 0.05-0.50% of citric acid, 0.4-1.5% of a penetrating agent, 0.1-1.0% of a surfactant and 0.04-0.1% of a stabilizing agent, with the balance being purified water. The inventionalso discloses a preparation method of the hydrogen peroxide disinfectant. The hydrogen peroxide disinfectant disclosed by the invention can be used for rapidly killing mycobacteria, and has good stability, catalyst resistance and strong anti-interference capability.

Owner:SHANGHAI LIKANG DISINFECTION HIGH TECH

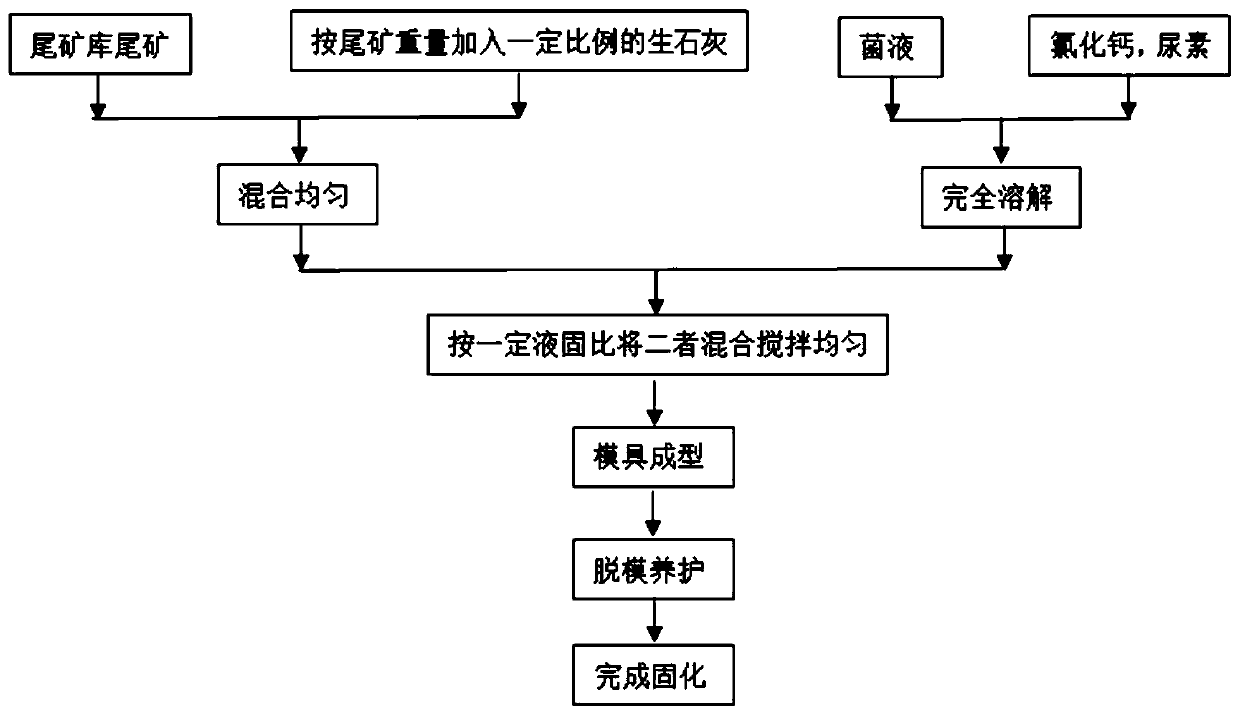

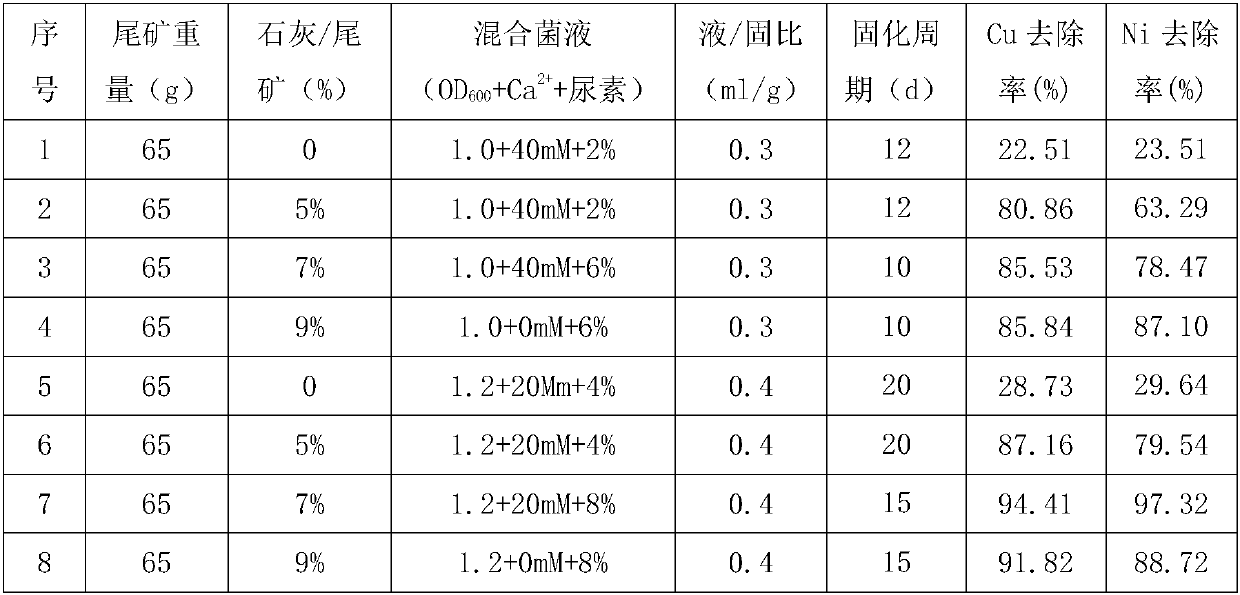

Method for mineralizing and fixing heavy metals in tailings by using lysinibacillus fusiformis and quicklime

PendingCN111534689AReduce leaching rateAvoid leachingBacteriaMicroorganism based processesEngineeringGenus Lysinibacillus

The invention discloses a method for mineralizing and fixing heavy metals in tailings by using lysinibacillus fusiformis and quick lime. The quick lime is used for improving the effect of mineralizingand fixing the heavy metals by microorganisms, the quick lime can generate calcium ions and hydroxyl ions when reacting with water, the generated calcium ions can provide a calcium source required bycalcification of the microorganisms, and the hydroxyl ions can improve the pH of a tailing solidification system; the lysinibacillus fusiformis simultaneously cement tailing particles with the quicklime while generating more calcium carbonate crystals to fix the heavy metals, so that the concentration of lead ions, copper ions, zinc ions and nickel ions in tailing leachate is reduced, the possibility that heavy metals in the tailings are leached and flow into nearby soil and rivers is greatly reduced, and large-scale environmental pollution is avoided; and meanwhile, a solidified body has certain compressive strength, so that a feasible idea is provided for resource utilization of the tailings.

Owner:ZHEJIANG UNIV OF TECH

Absorptive composition for infrared ray and absorptive resin composition for infrared ray

InactiveCN1856560APrevent blackeningExcellent visible light transmissionOther chemical processesOptical elementsInfraredAlkaline earth metal

An absorptive composition for an infrared ray which comprises an infrared ray absorbing agent comprising a di-valent ionic copper compound and a preventive agent for blackening comprising a metal salt compound; an absorptive resin composition for an infrared ray which comprises a resin component and the above infrared ray absorbing agent and preventive agent for blackening; and articles prepared by the application of the composition or the resin composition. The di-valent ionic copper compound is preferably a phosphorus-containing copper compound. The metal salt compound as the preventive agent for blackening is a compound comprising a metal selected from among an alkali metal, an alkaline earth metal and a transition metal. The absorptive composition for an infrared ray has the above infrared ray absorbing agent, is inhibited or suppressed in the blackening phenomenon due to an ultraviolet ray, and exhibits excellent transmittance of a visible light and excellent absorptivity for an infrared ray over a long period of time with stability. The above applied articles include a formed article, a sheet, a film, an intermediate film for a laminated glass, a composite having adsorptive property for an infrared ray and a window material.

Owner:KUREHA KAGAKU KOGYO KK

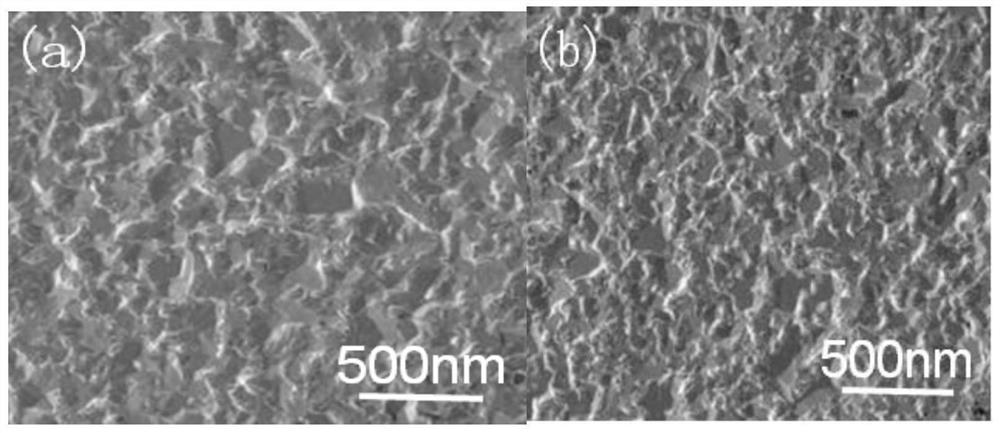

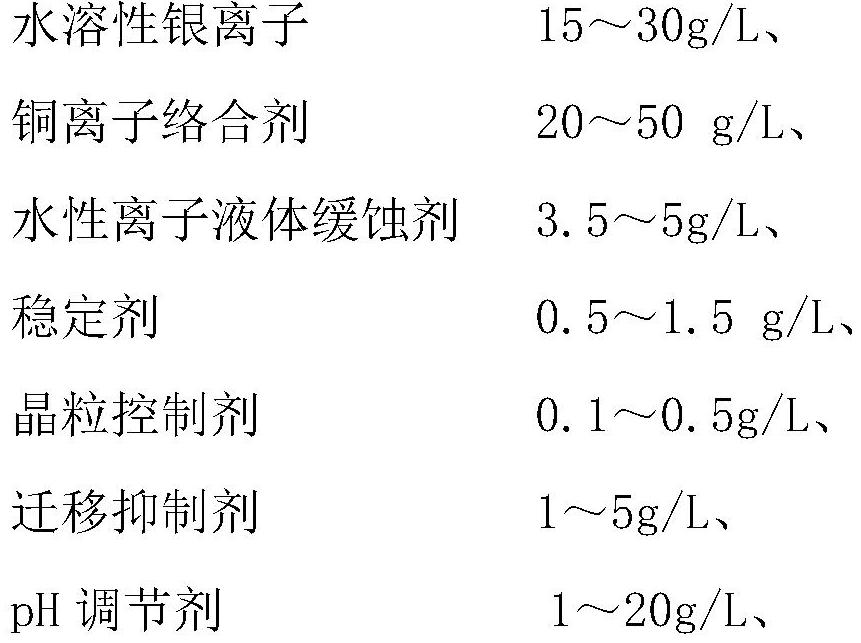

Chemical silver plating solution for printed circuit board and preparation method of circuit board

InactiveCN111876760AAvoid environmental problemsReduces tendency to bite copper wireVacuum evaporation coatingSputtering coatingChemical platingMetallurgy

The invention discloses a chemical silver plating solution for a printed circuit board. The chemical silver plating solution comprises the following components including 15-30 g / L of water-soluble silver ions, 20-50 g / L of a copper ion complexing agent, 3.5-5 g / L of a water-based ionic liquid corrosion inhibitor, 0.5-1.5 g / L of a stabilizer, 0.1-0.5 g / L of a grain control agent, 1-5 g / L of a migration inhibitor and 1-20 g / L of a pH regulator, wherein the pH value is 5.5-6.5. The chemical silver plating solution can effectively reduce the tendency of etching a copper wire in the subsequent preparation process of the printed circuit board, can obtain the circuit board with a compact plating layer, uniform grain size and good conductivity and corrosion resistance, can effectively reduce the production cost, and can be widely used for production in the printed circuit industry.

Owner:广州市豪越新能源设备有限公司

Aqueous alkaline zincate solutions and method for depositing zincate coating on aluminium or aluminium substrate

The present invention provides an improved aqueous alkaline zincate solution comprising hydroxide ions, zinc ions, nickel ions and / or cobalt iron ions, copper ions, and at least one inhibitor containing one or more nitrogen atoms, sulfur atoms, or both nitrogen and sulfur atoms provided said nitrogen atoms are not present in an aliphatic amine or hydroxylamine. The present invention also relates to methods for depositing zincate coatings on aluminum and aluminum alloys comprising applying an immersion zincate coating on an aluminum or aluminum alloy substrates, optionally followed by plating the zincate coated aluminum or aluminum alloy substrate using an electroless or electrolytic metal plating solution.

Owner:ATOTECH DEUT GMBH

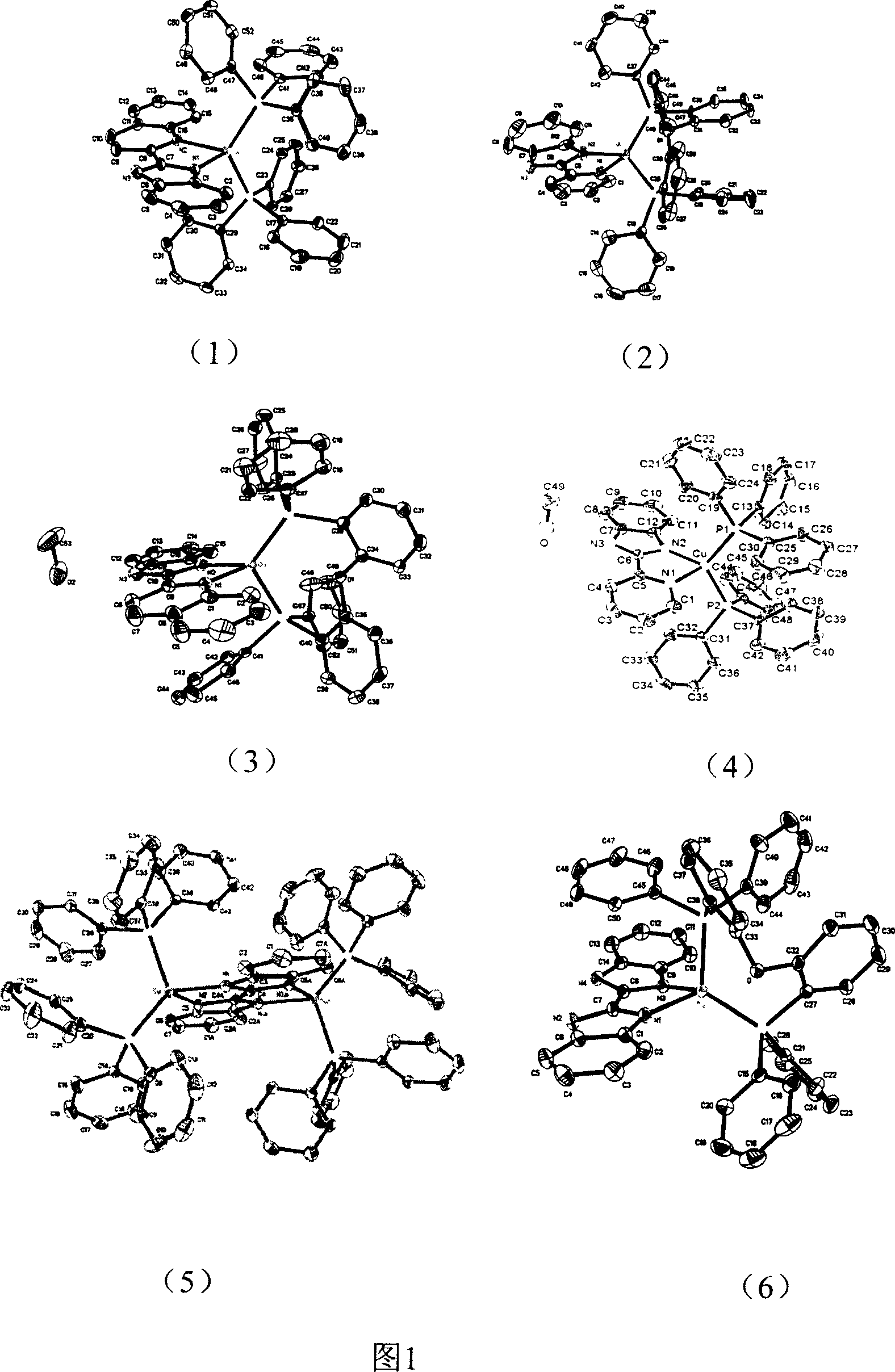

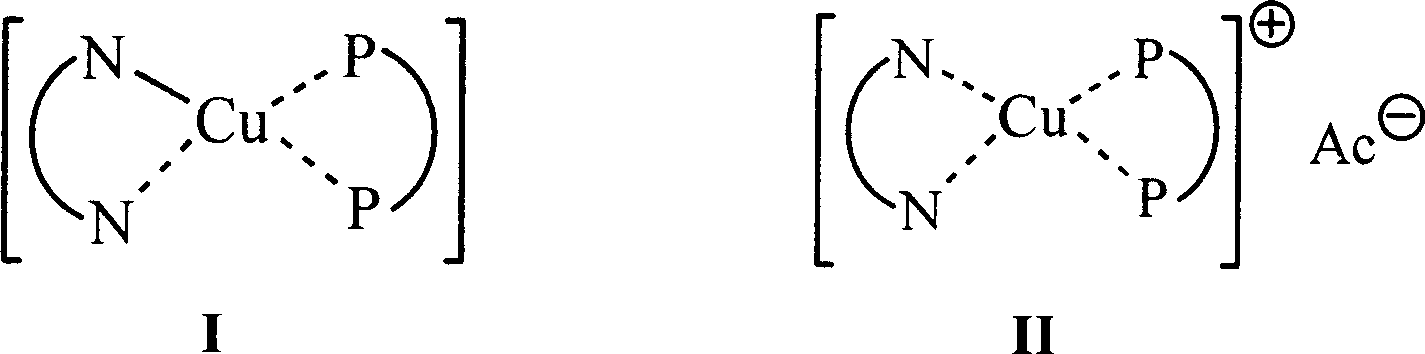

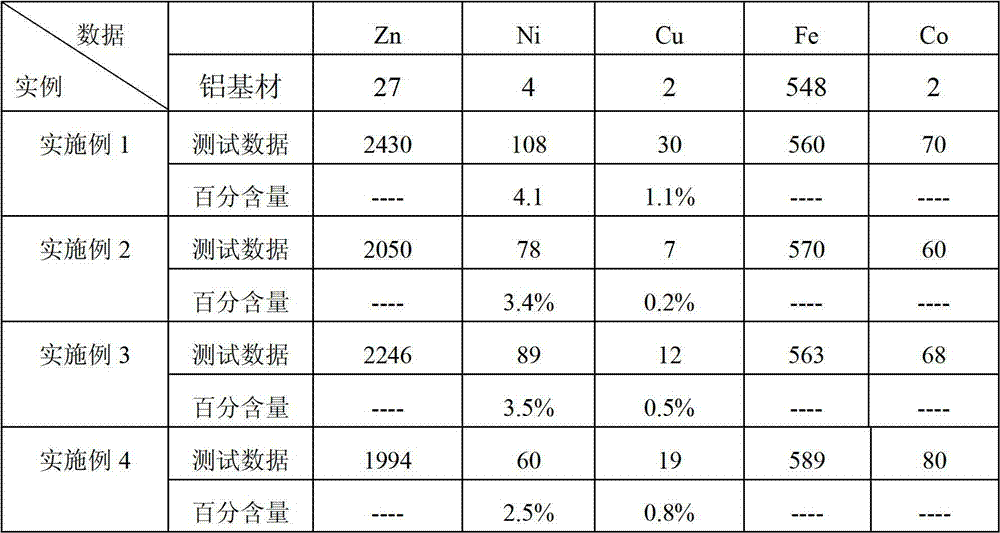

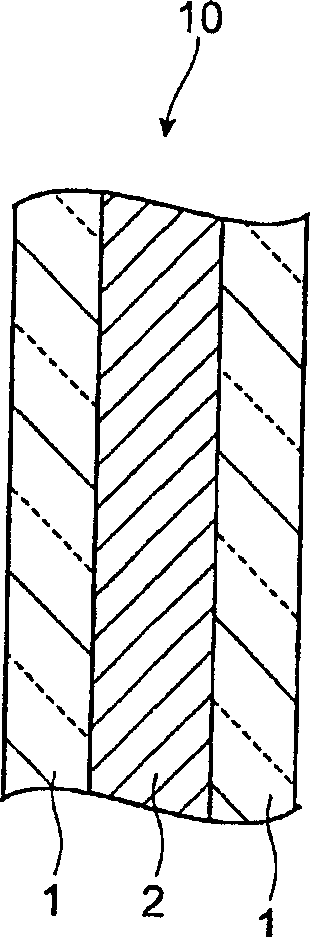

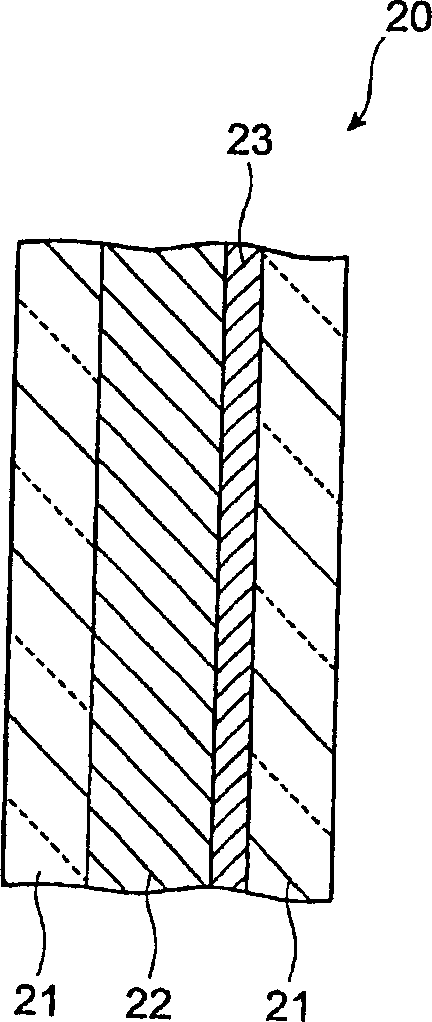

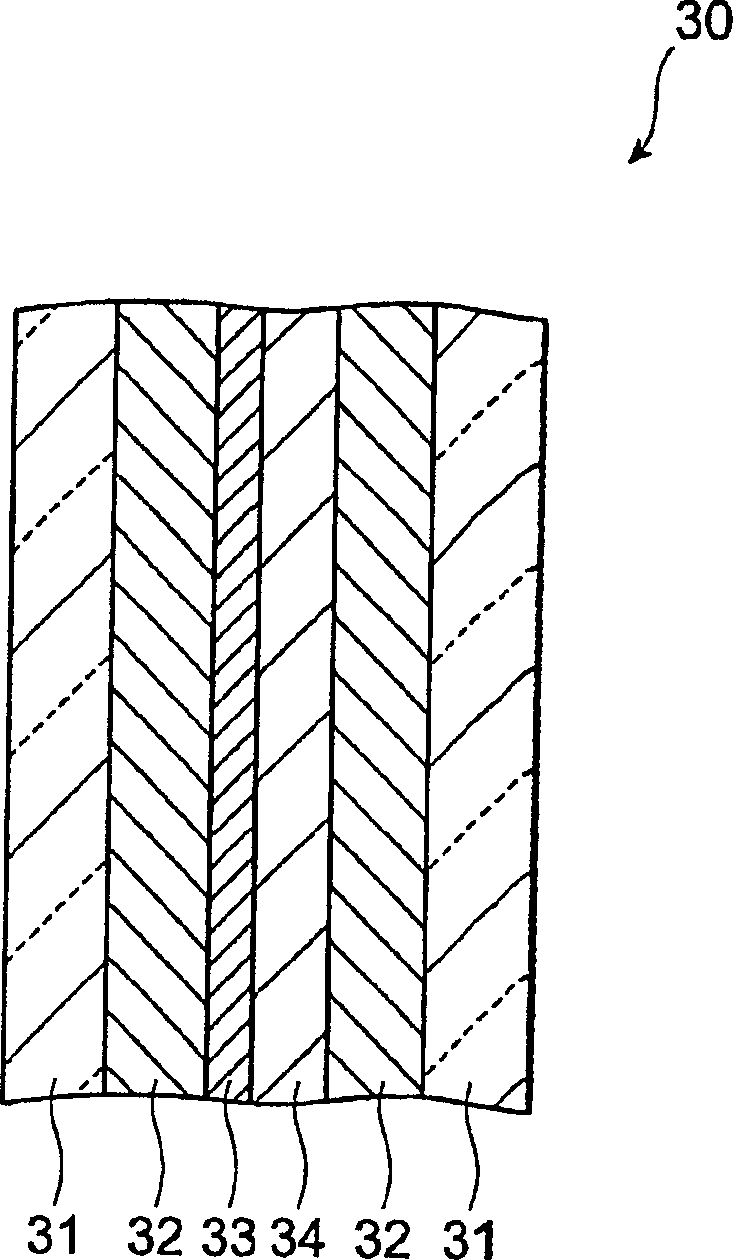

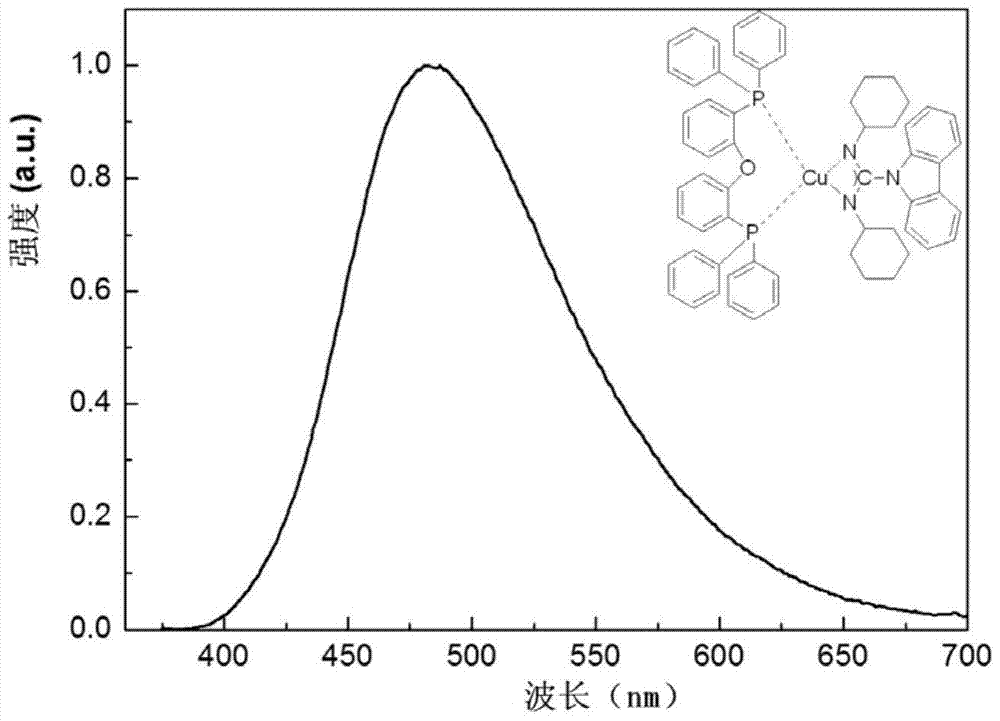

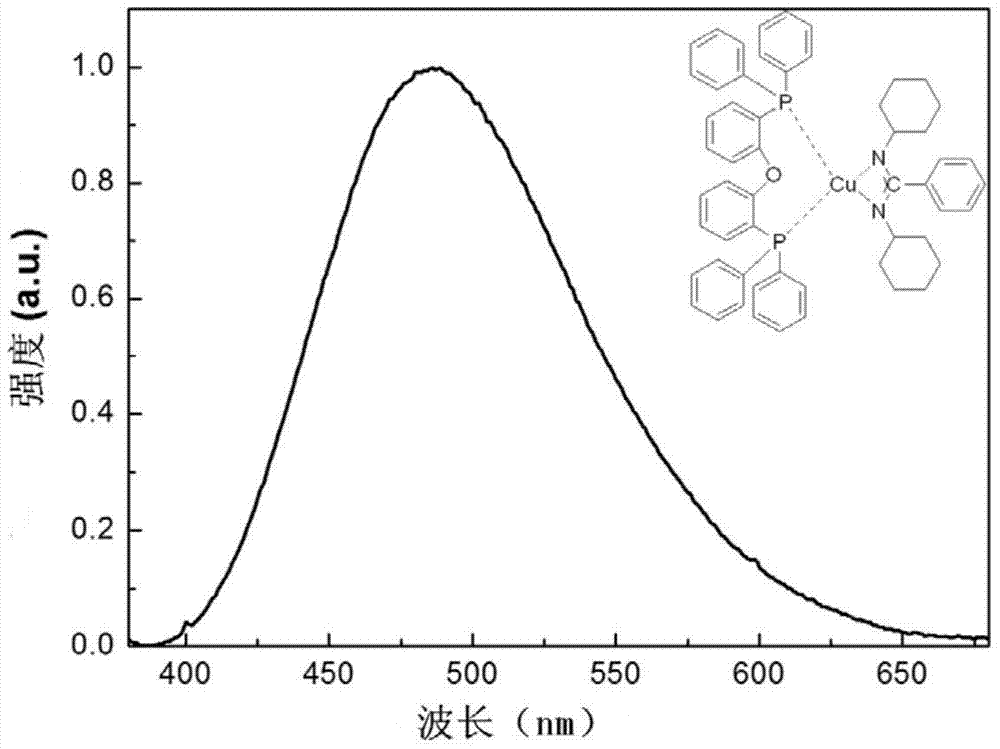

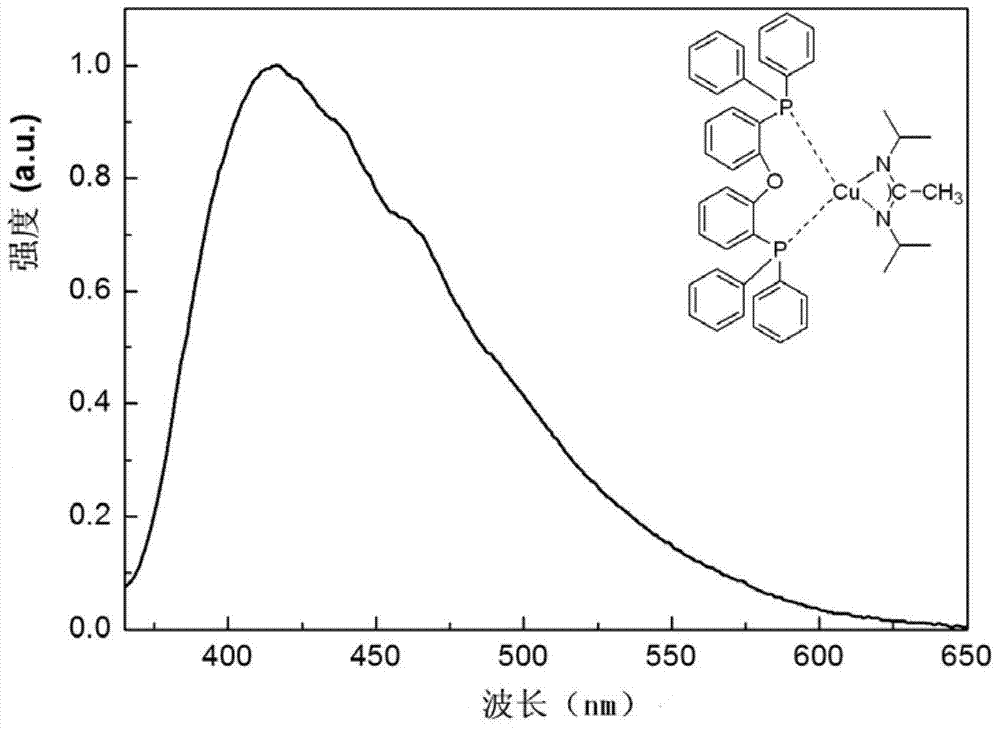

Monomer copper (I) complex material used for blue or/and green light emission

ActiveCN104844629AImprove stabilityGroup 1/11 organic compounds without C-metal linkagesGroup 5/15 element organic compoundsGreen-lightOrganic electroluminescence

The invention relates to a monomer copper (I) complex material used for blue or / and green light emission. Structure general formula of the monomer copper (I) complex material is represented by a formula in the invention, wherein one symbol is used for representing an amidine derivative ligand, and another symbol is used for representing two independent aromatic phosphine ligands or bridge-linked aromatic phosphonic bidentate ligands. The monomer copper (I) complex material is a neutral copper (I) complex. Compared with ionic complexes, the neutral copper (I) complex possesses excellent stability in vacuum evaporation because that no counter ion exists, so that application prospect is promising. The monomer copper (I) complex material possesses excellent stability because that no other ligating atom exists, and conversion into ionic copper (I) complex caused by reaction with surrounding environment is not easily caused; the complex luminous zone is mainly distributed in the blue light region, the green light region, or the blue-green light region. The monomer copper (I) complex material can be used for organic electroluminescence devices and sensors.

Owner:江苏纳兹博材料科技有限公司

Method for preparing infiltrated copper-chromium contact material by spark plasma sintering

ActiveCN106180654BImprove performanceGuaranteed performanceFoundry mouldsFoundry coresVacuum pumpingPulsed DC

The invention discloses a method for preparing an infiltrated copper-chromium contact material by spark plasma sintering. Step 1: Pour chromium powder into a graphite mold, restore the powder, and then place it in a plasma sintering furnace to evacuate and pressurize. Pass in a pulsed direct current and heat up to 1050-1380°C, keep warm for 2.5-5min, and then cool with the furnace; step 2, take the copper block and polish it, clean it with ultrasonic waves, dry it, scan it with laser light, and then conduct plasma treatment. Obtain the infiltrated copper block; step 3, put the chromium skeleton into the graphite boat, place the infiltrated copper block on the chromium skeleton, fill it with corundum powder around it, place it in a high-temperature sintering furnace with a protective gas atmosphere, and heat up to After 1150-1300°C, heat preservation for 40-60min to obtain a copper-chromium sintered body; step 4, vacuumize and hot-press the copper-chromium sintered body at a pressure of 50-100MPa and a temperature of 800-850°C, and then cool to At room temperature, the copper-chromium contact material is prepared. The production method of the invention has the advantage of shortening the production cycle.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

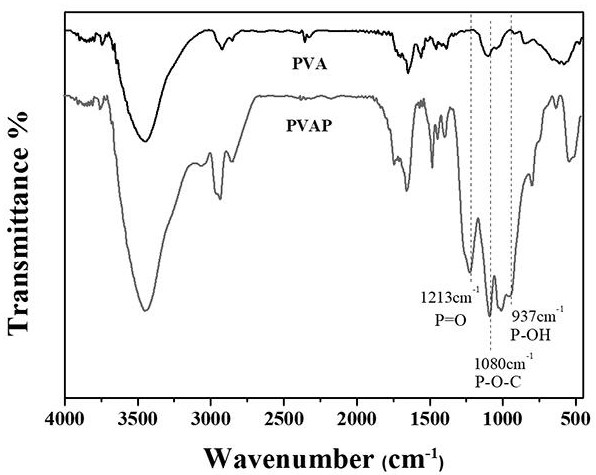

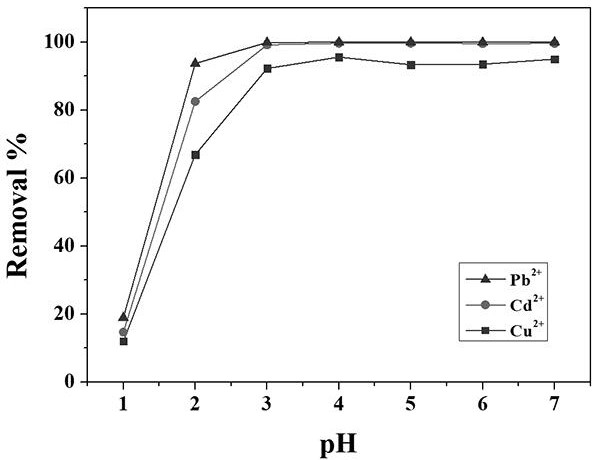

Adsorbent for ultra-rapidly removing heavy metal ions in acidic wastewater

ActiveCN112387258AImprove water resistanceEasy to synthesizeOther chemical processesWater contaminantsPhosphoric Acid EstersPolyvinyl alcohol

The invention discloses an adsorbent for ultra-rapidly removing heavy metal ions in acid wastewater, and belongs to the field of sewage treatment and environmental protection. A specific preparation method comprises the steps: reacting polyvinyl alcohol with phosphorus pentoxide to obtain the polyvinyl alcohol phosphate adsorbent. The polyvinyl alcohol phosphate adsorbent prepared by the preparation method disclosed by the invention has an ultrafast adsorption rate and excellent adsorption capacity on lead ions, copper ions and cadmium ions under an acidic condition, and can be applied to removal of heavy metal ions in acidic wastewater.

Owner:UNIV OF JINAN

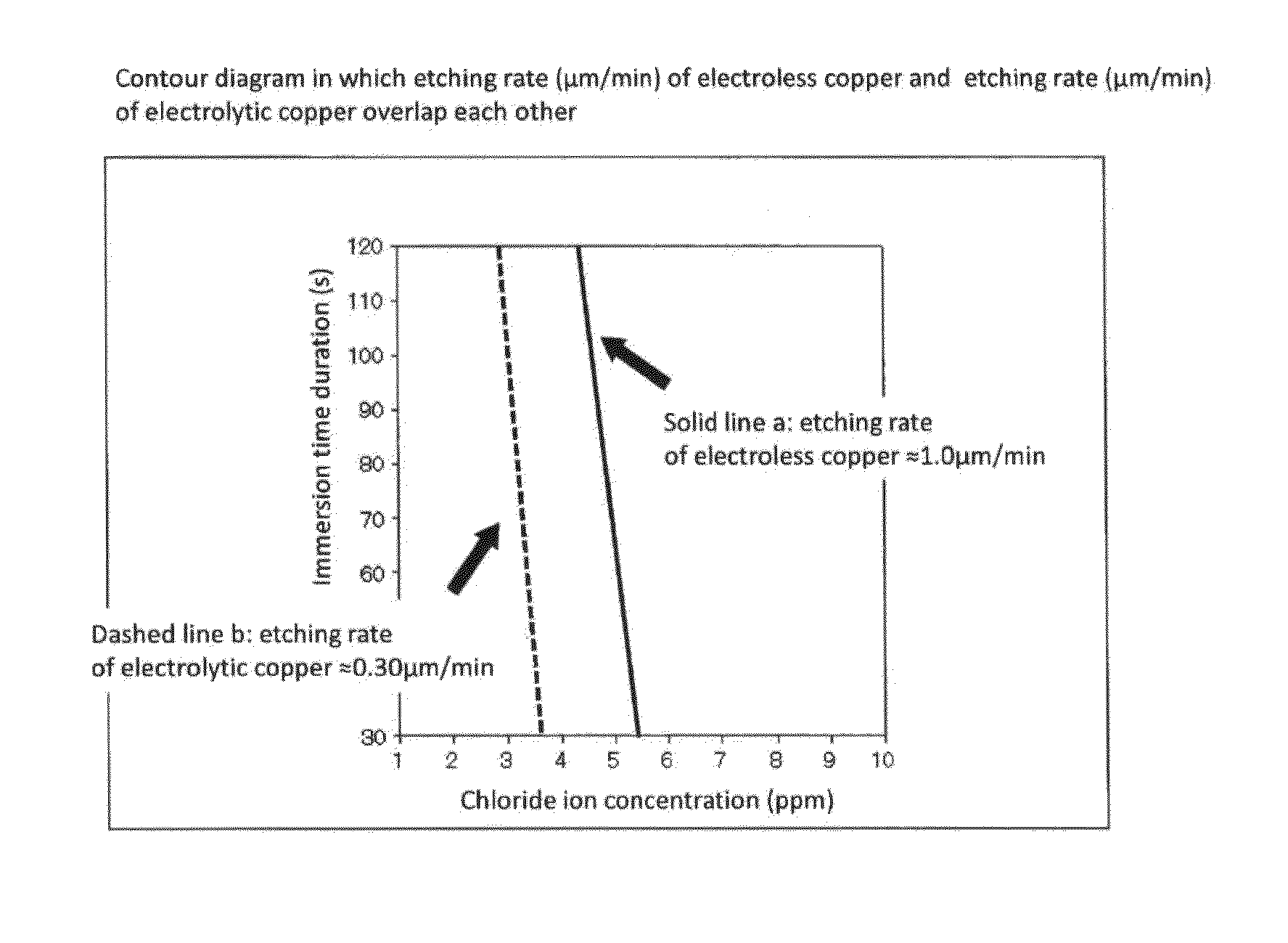

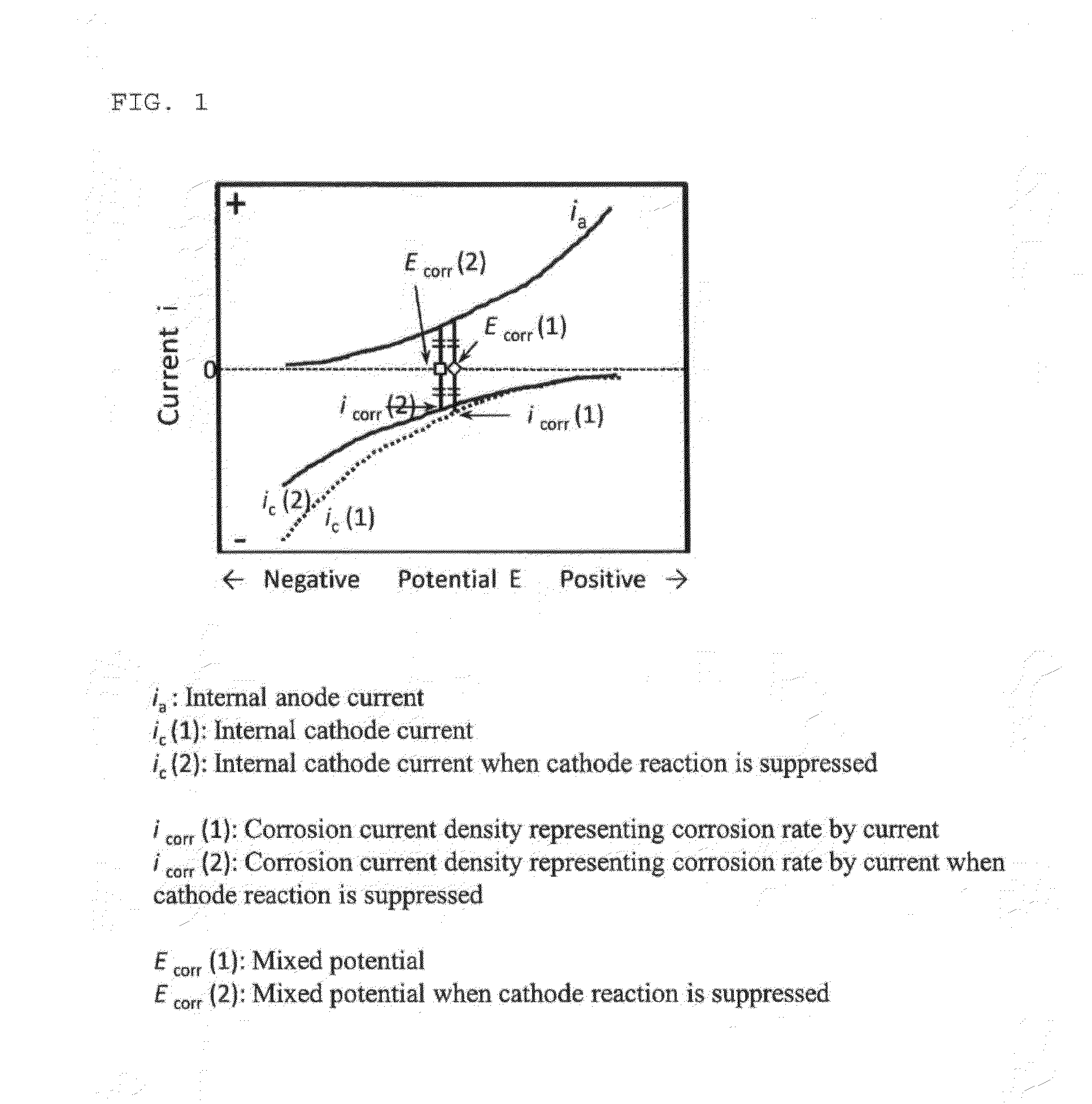

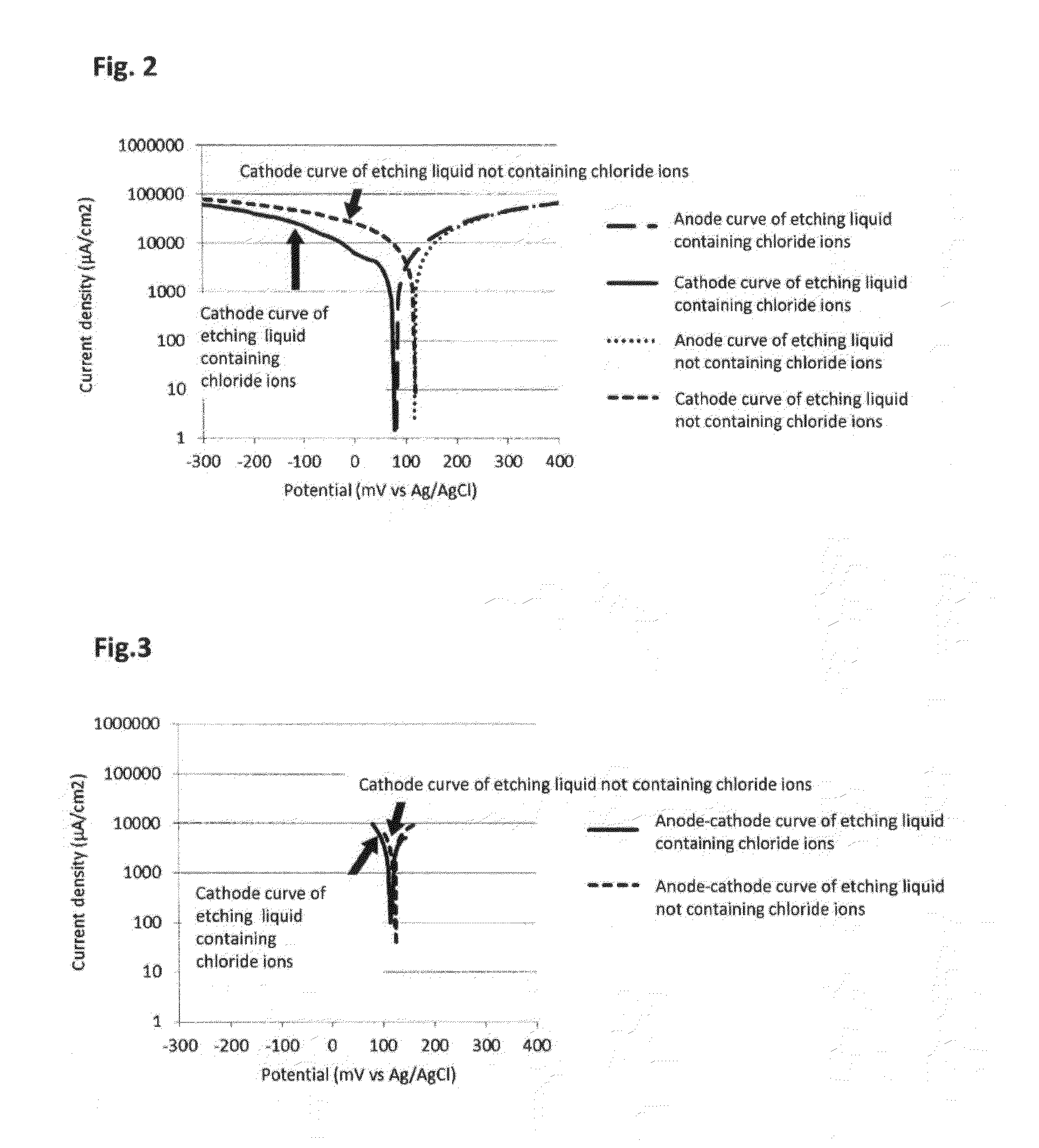

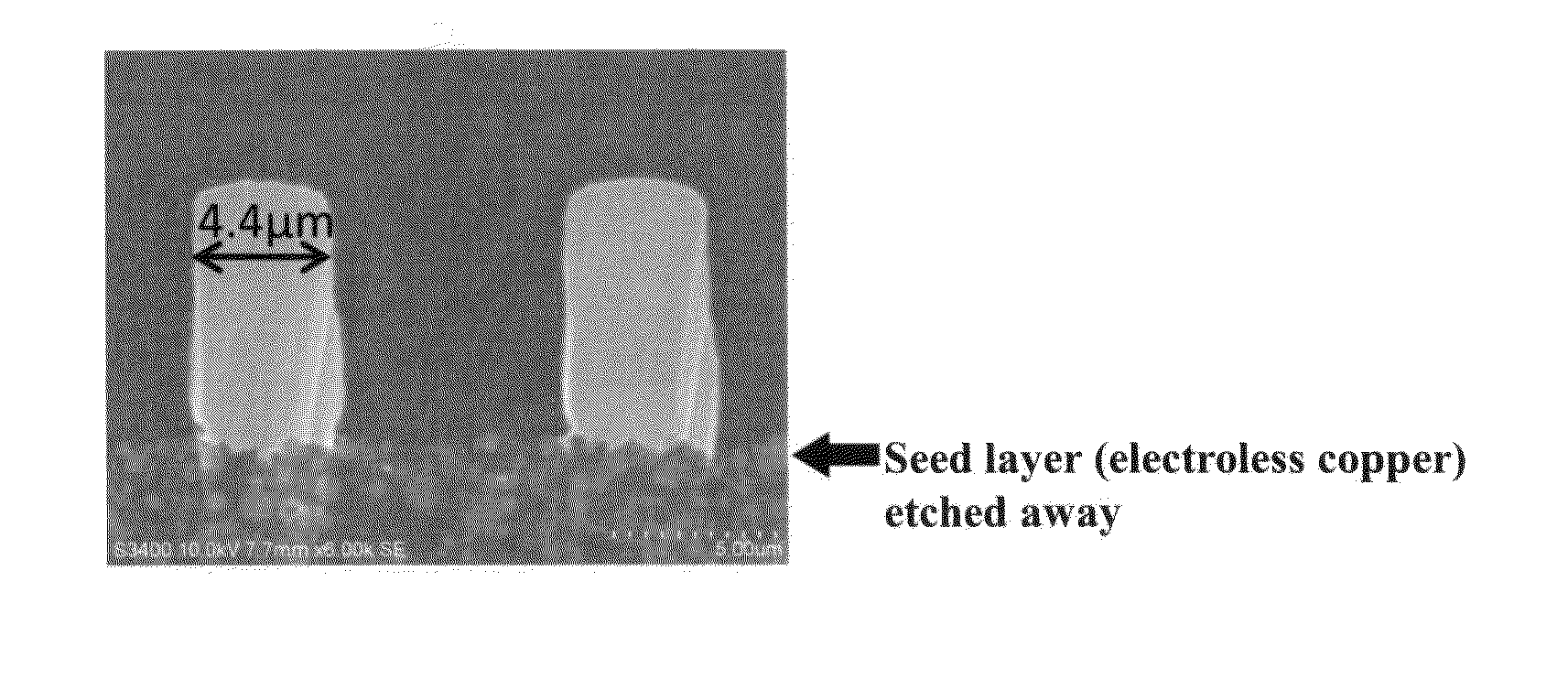

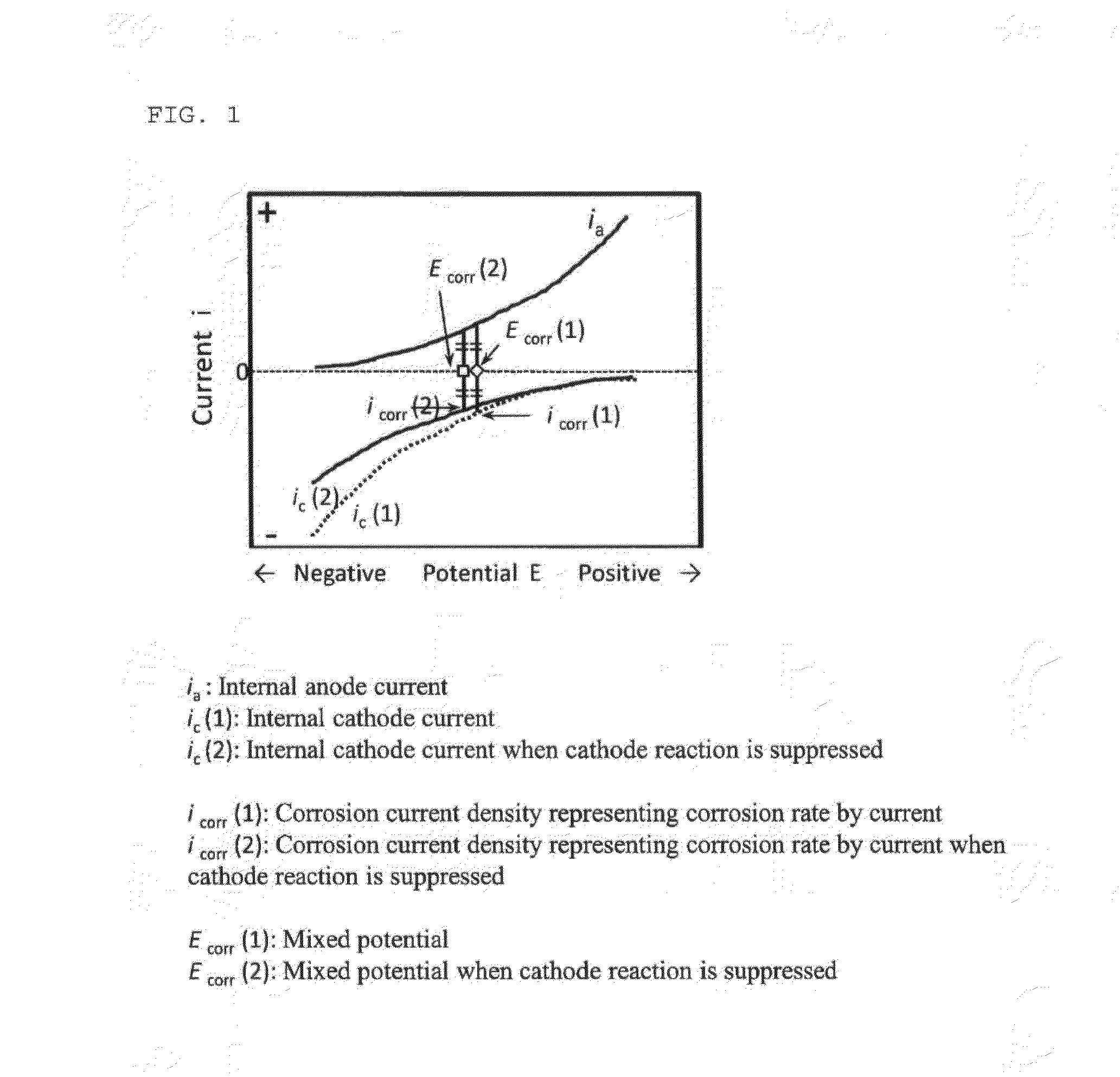

Method of treating wiring substrate and wiring substrate manufactured by the same

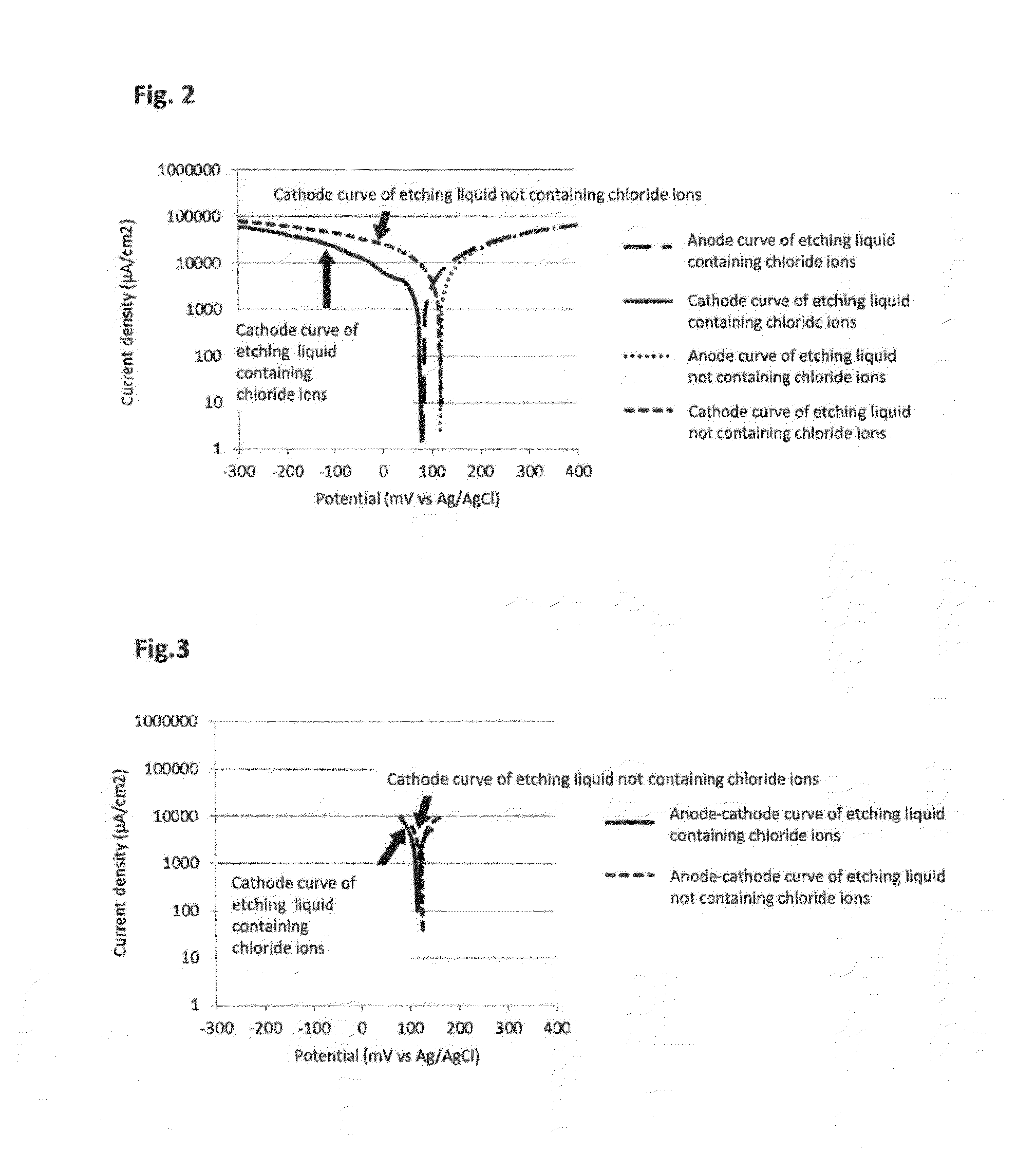

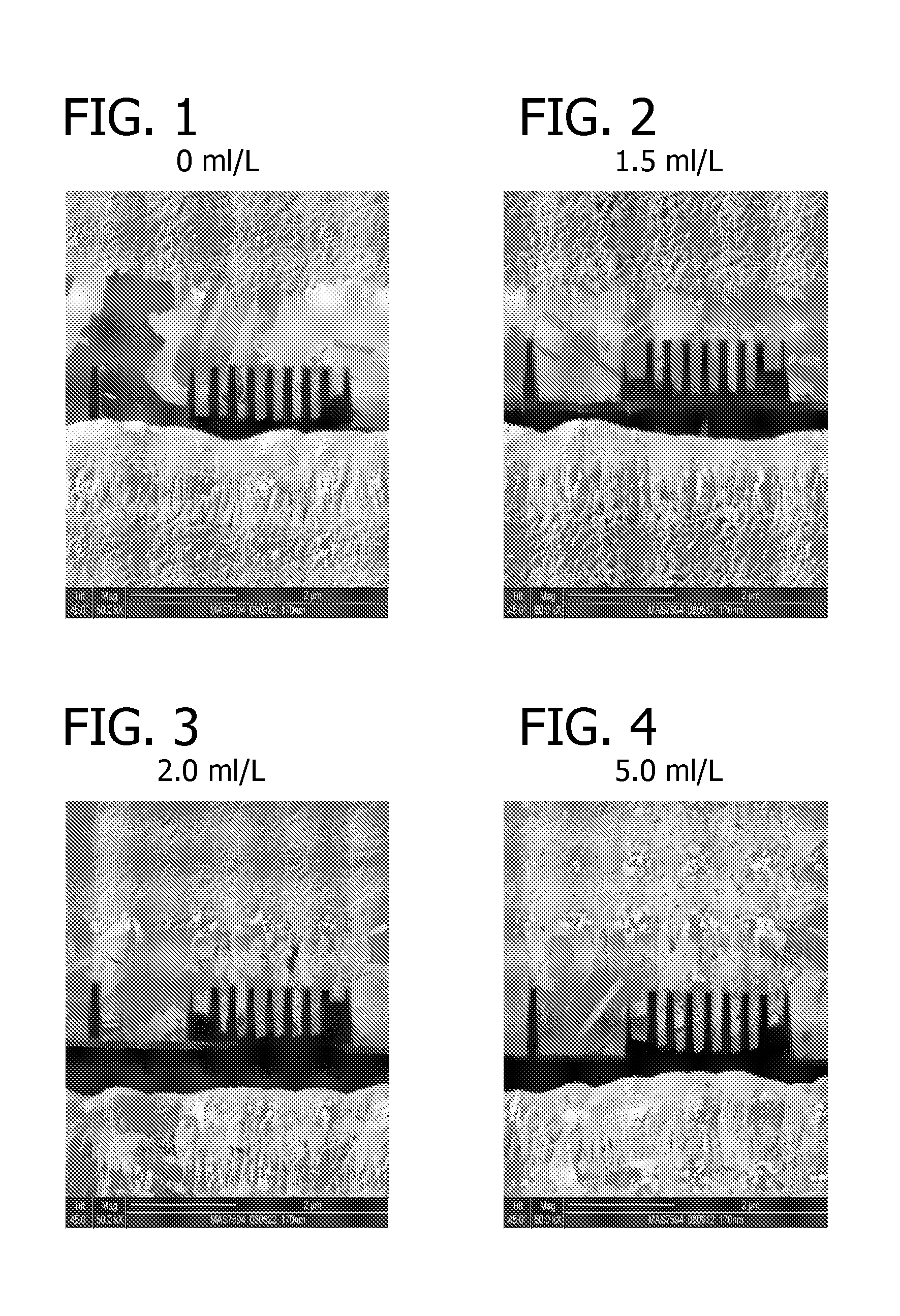

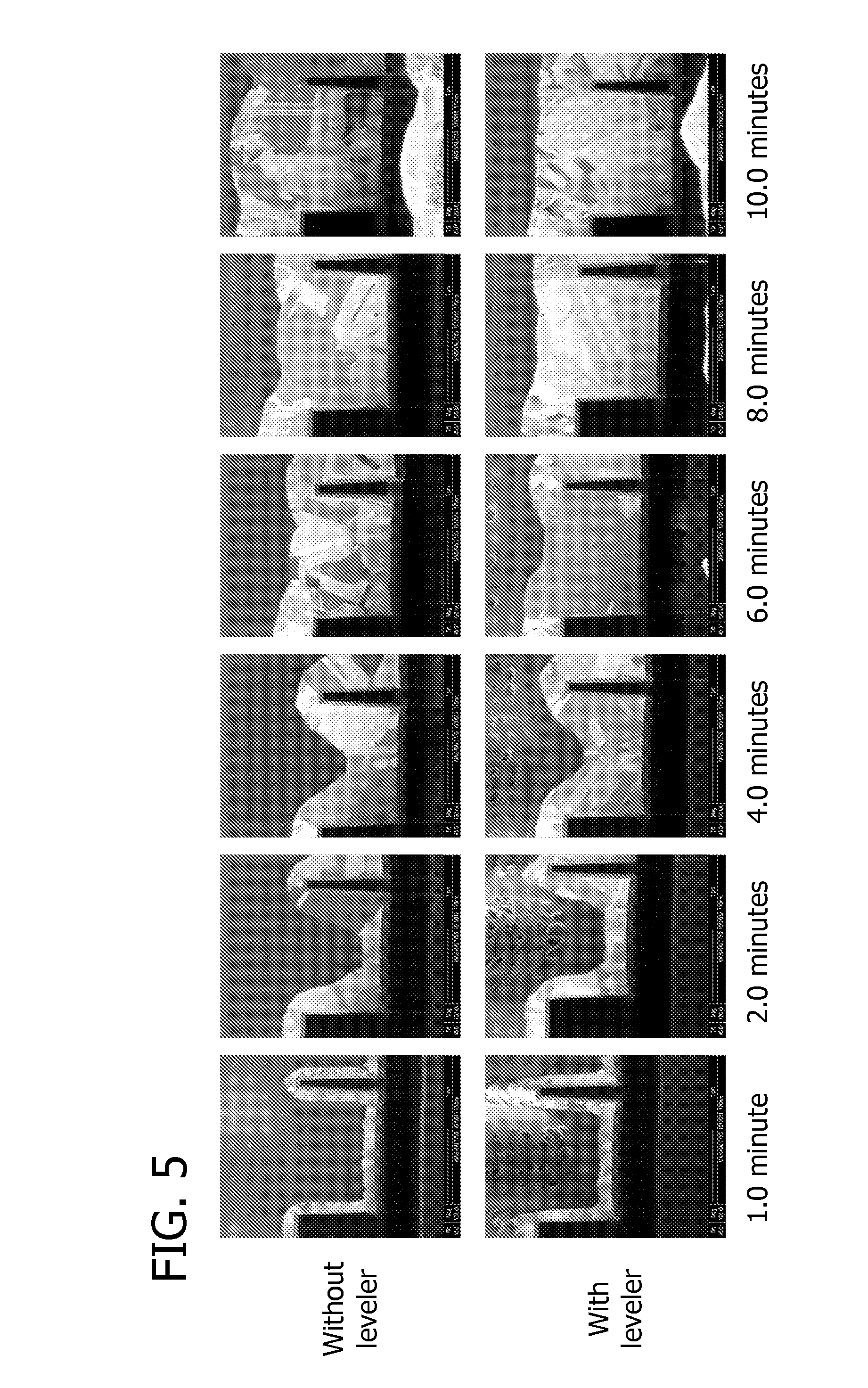

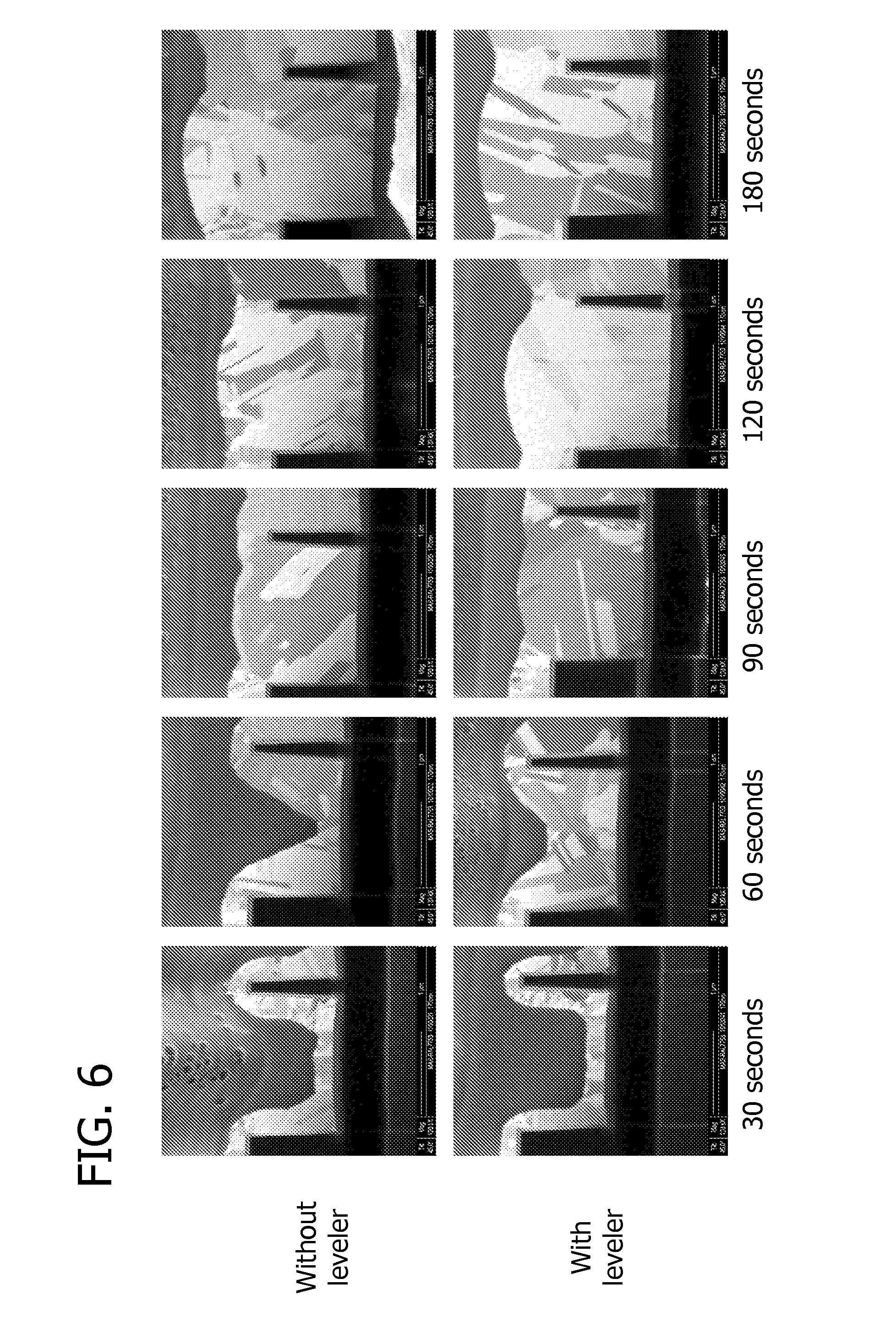

ActiveUS9301399B2High selectivityReduce the amount of solutionInsulating substrate metal adhesion improvementSemiconductor/solid-state device manufacturingTetrazolePhysical chemistry

A method of treating a wiring substrate according to an embodiment includes, in a semi-additive process:(1) contacting the wiring substrate with a pre-etching treatment liquid composition containing a chloride ion, the wiring substrate containing a seed layer formed of an electroless copper and a wiring pattern formed of an electrolytic copper; and(2) continuously, etching the wiring substrate with an etching liquid composition containing a hydrogen peroxide, a sulfuric acid, a tetrazole, a chloride ion, a copper ion and a water.

Owner:MITSUBISHI GAS CHEM CO INC +1

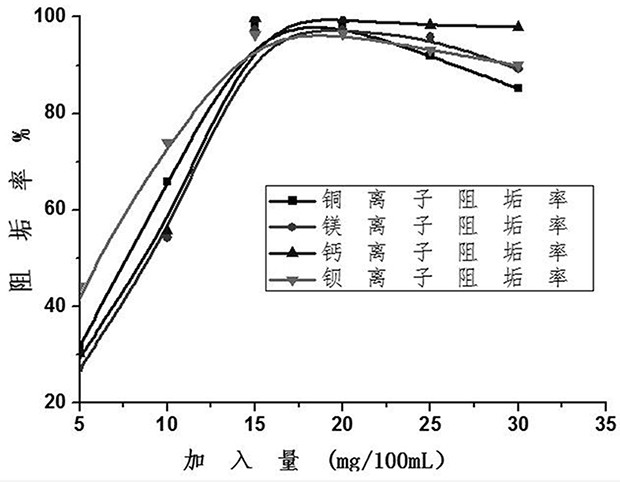

Phosphorus-free reverse osmosis membrane scale inhibitor and preparation method thereof

PendingCN113967411AExcellent anti-scaling performanceHigh scale inhibition rateSemi-permeable membranesGeneral water supply conservationPentamethylcyclopentadieneActive agent

The invention relates to the technical field of water treatment, in particular to a phosphorus-free reverse osmosis membrane scale inhibitor and a preparation method thereof. The phosphorus-free reverse osmosis membrane scale inhibitor is prepared from the following raw materials in percentage by mass: 10 to 15 percent of polyaspartic acid, 50 to 65 percent of polyepoxysuccinic acid, 15 to 20 percent of chitosan, 5 to 10 percent of polyacrylic acid, 1 to 5 percent of anionic surfactant and 3 to 5 percent of bis (pentamethylcyclopentadiene) zinc. The phosphorus-free reverse osmosis membrane scale inhibitor disclosed by the invention can be used for desalting industrial and domestic wastewater containing various heavy metals, and has a relatively high scale inhibition rate on calcium ions, barium ions, magnesium ions and copper ions.

Owner:威海君创环保科技有限公司

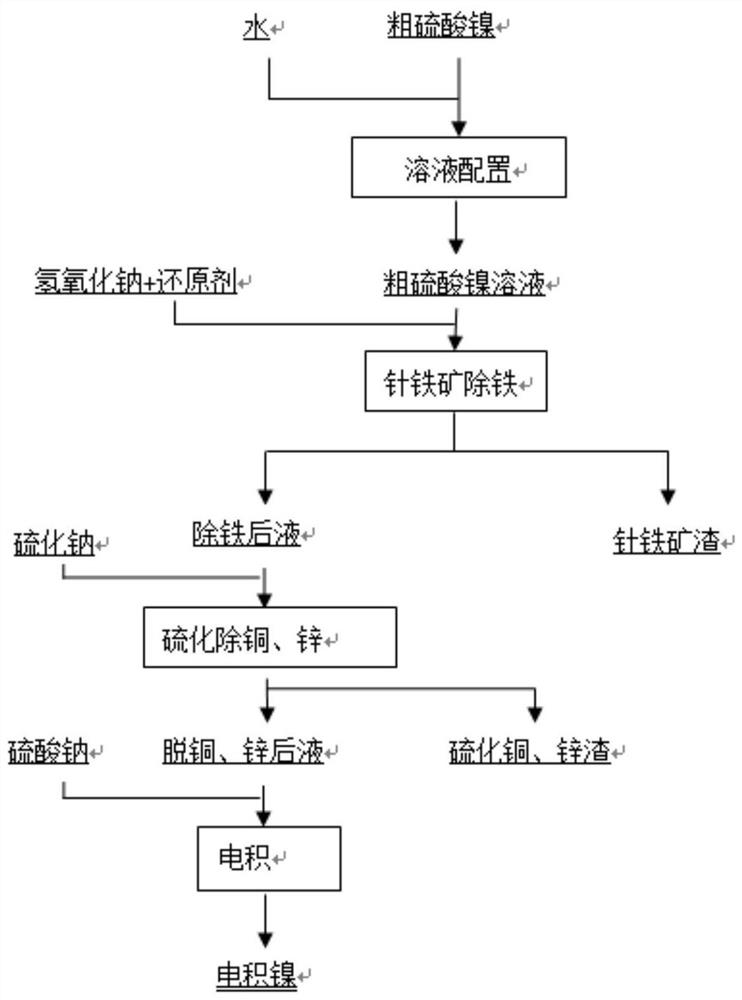

Method for preparing electrodeposited nickel by using crude nickel sulfate

InactiveCN113322489ARaise the gradeSimple methodElectrolysis componentsPhotography auxillary processesSeed crystalMaterials science

The invention provides a method for preparing electrodeposited nickel by using crude nickel sulfate. The method comprises the following steps: mixing a crude nickel sulfate solution and goethite seed crystals at 90-115 DEG C, adding a reducing agent, controlling the concentration of ferric iron not to exceed 2g / L, regulating the pH value to 2.5-4 by using a sodium hydroxide solution, reacting until no precipitate is produced, and filtering to obtain filtrate and FeOOH crystals; the crude nickel sulfate solution comprises nickel ions, iron ions, copper ions and zinc ions; the pH value of the crude nickel sulfate solution is less than or equal to 2; adjusting the pH value of the filtrate to 4-5, adding a sodium sulfide solution, and filtering to obtain a purified solution; conducting electrodeposition extraction on the purified liquid to obtain the nickel. The method for preparing electrodeposited nickel by using crude nickel sulfate is simple, and the crude nickel sulfate is purified to meet the requirement of electrodeposited nickel, so that high-grade metal nickel is obtained.

Owner:YANGGU XIANGGUANG COPPER

Site fast detection method for copper, zinc, lead and cadmium as heavy metals in seawater

ActiveCN102798657BReduce usageDoes not affect normal useMaterial electrochemical variablesSquare wave anodic stripping voltammetryIonic liquid

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

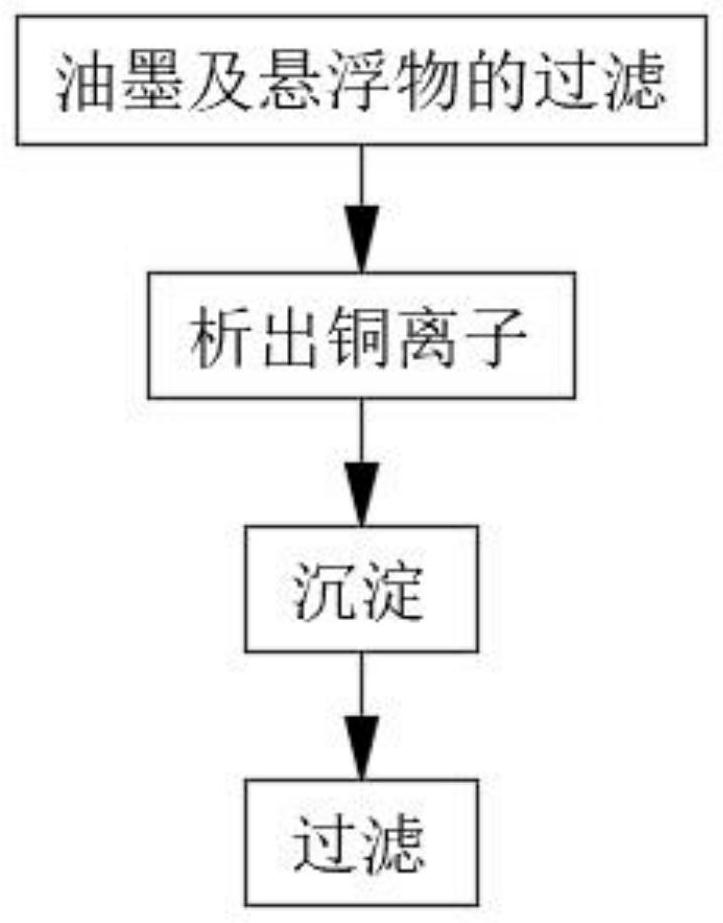

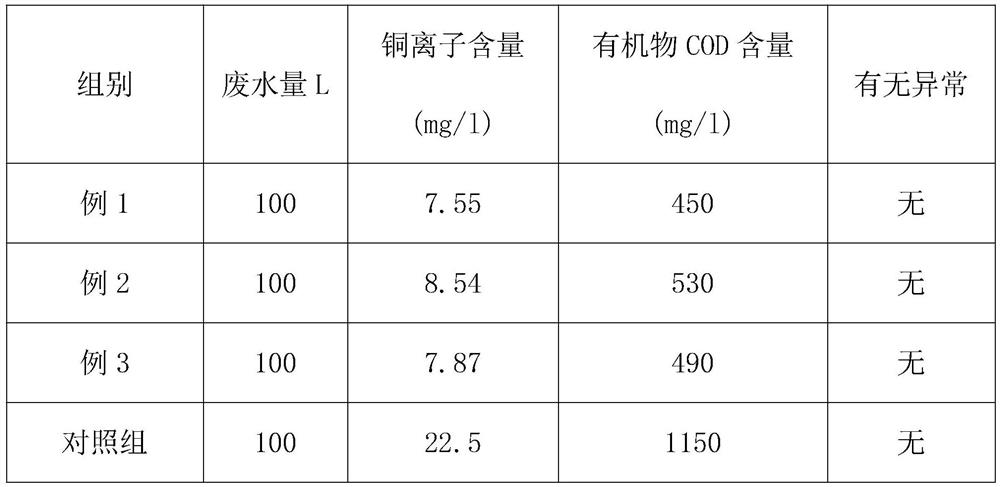

Method for treating copper-containing printing ink wastewater

The invention discloses a method for treating copper-containing printing ink wastewater, which belongs to the technical field of industrial wastewater and comprises the following steps that filtered pretreated wastewater is pumped into a sedimentation tank, ferrous sulfate powder is added into the sedimentation tank, copper ions are replaced in the wastewater by iron ions, flow-separated copper ions are formed in the wastewater, meanwhile, caustic soda flakes are added into the sedimentation tank to automatically adjust the PH value, a sulfur-containing high-molecular compound is added into the wastewater, metal ion copper reacts with the sulfur-containing high-molecular compound to be fixed, a copper sulfide solid which is not easy to dissolve in water is formed and floats in the wastewater, then a coagulant aid is added into the wastewater, electrification is carried out for neutralization and flocculation, and precipitation of floating solids is promoted. According to the method, organic matter printing ink in the copper-containing printing ink wastewater is removed through acidification, COD is degraded, a large number of copper ions in the wastewater are removed through a chemical precipitation method, the cost is low, and the generated copper-containing sludge is high in recycling value.

Owner:FAIR RAYS ELECTRONICS TECH SHENZHEN LTD

Method of treating wiring substrate and wiring substrate manufactured by the same

ActiveUS20140311778A1Increase selection ratioHigh densitySemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingIonChemistry

A method of treating a wiring substrate according to an embodiment includes, in a semi-additive process:(1) contacting the wiring substrate with a pre-etching treatment liquid composition containing a chloride ion, the wiring substrate containing a seed layer formed of an electroless copper and a wiring pattern formed of an electrolytic copper; and(2) continuously, etching the wiring substrate with an etching liquid composition containing a hydrogen peroxide, a sulfuric acid, a tetrazole, a chloride ion, a copper ion and a water.

Owner:MITSUBISHI GAS CHEM CO INC +1

Defect reduction in electrodeposited copper for semiconductor applications

InactiveUS20080121527A1Few defectImprove surface morphologyAnodisationSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

A method for electroplating a copper deposit onto a semiconductor integrated circuit device substrate having submicron-sized features, and a concentrate for forming a corresponding electroplating bath. A substrate is immersed into an electroplating bath formed from the concentrate including ionic copper and an effective amount of a defect reducing agent, and electroplating the copper deposit from the bath onto the substrate to fill the submicron-sized reliefs. The occurrence of protrusion defects from superfilling, surface roughness, and voiding due to uneven growth are reduced, and macro-scale planarity across the wafer is improved.

Owner:MACDERMID ENTHONE INC

High-pressure sprayed surface long-acting antibacterial agent

PendingCN114342957AGood compatibilityIncrease potency oftenBiocideAntifouling/underwater paintsSilver ionAntibacterial agent

The invention discloses a high-pressure sprayed surface long-acting antibacterial agent which comprises the following raw materials in percentage: 10-15% of kaolin powder, 5-8% of talcum powder, 50-60% of deionized water, 8-12% of sodium dihydrogen phosphate, 5-10% of silver ions, 3-5% of zinc ions, 3-5% of copper ions, 4-8% of an antibacterial synergist, 4-8% of a dispersing agent and 1-3% of borax. Wherein the dispersing agent comprises one or two of sodium oleate, sulfate salt, sulfonate and polyhydric alcohol.

Owner:物衍科技(北京)有限公司

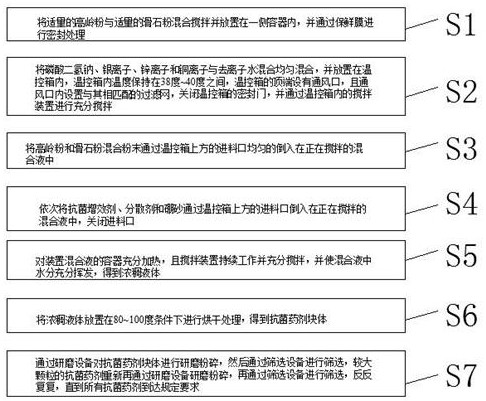

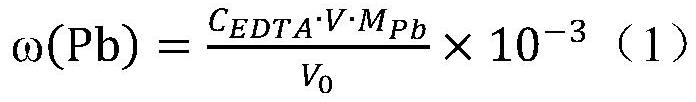

Method for measuring lead content in casting lead brass lead washing bath solution

PendingCN114487264AEasy to getSimple processChemical analysis using titrationPreparing sample for investigationAluminum IonZinc ion

The invention relates to a method for measuring the content of lead in a casting lead brass lead washing bath solution, which comprises the following steps of: sequentially filtering and removing aluminum ions, zinc ions and copper ions by adopting a method of precipitating and then dissolving aiming at main interference factors of copper ions, zinc ions and aluminum ions; and finally, completely converting the residual lead sulfide precipitate into lead sulfate precipitate, adjusting the pH value, dissolving the lead sulfate precipitate, adding xylenol orange as an indicator, adding a phenanthroline aqueous solution to shield residual copper, zinc and aluminum ions, and titrating the lead ion concentration by using an EDTA standard solution. The method is suitable for measuring the concentration of trace lead ions (ppm level) in the lead washing bath solution, can achieve the effect of removing interference ions such as copper, zinc, aluminum and the like to the greatest extent while hardly losing the lead ions, and is simple in process, convenient to operate, obvious in phenomenon, easy to judge and high in accuracy.

Owner:JOMOO KITCHEN & BATHROOM

Fluorophosphate glass

ActiveCN110734222BHigh hardnessImproved coefficient of thermal expansionAluminum IonThermal dilatation

Owner:PLATINUM OPTICS TECH SUZHOU INC +1

Fluorophosphate glass

ActiveCN110734222AHigh hardnessImproved coefficient of thermal expansionAluminum IonThermal dilatation

The invention discloses fluorophosphate glass comprising phosphorus ions, aluminum ions, zirconium ions, copper ions, alkali metal ions, alkali earth ions and divalent metal ions, wherein the weight percentage of the phosphorus ions is 18%-25%; the weight percentage of the aluminum ions is 11%-21%; the weight percentage of the zirconium ions is 0.5%-7%; the weight percentage of the copper ions is0.1%-10%; the weight percentage of the alkali metal ions is 6%-18%; the weight percentage of the alkaline earth ions is 27-58%; and the weight percentage of the divalent metal ions is 27-58%. The hardness of the fluorophosphate glass is greater than 400 HK, and the thermal expansion coefficient of the fluorophosphate glass is less than or equal to 14*10<-6> k<-1>, so that the fluorophosphate glasshas high hardness and good thermal expansion coefficient; the fluorophosphate glass is not easy to break when being thinned, and the thickness of the fluorophosphate glass can be less than or equal to 0.1 mm.

Owner:PLATINUM OPTICS TECH SUZHOU INC +1

A kind of solid phase extraction column and its preparation method and application

ActiveCN108392853BGood chemical stabilityHigh detection sensitivityOther chemical processesPreparing sample for investigationHydrogen phosphateSorbent

The invention discloses a solid phase extraction column for trace determination on heavy metal in a marine food product and a preparation method of the solid phase extraction column. An adsorbent of the solid phase extraction column is tin hydrogen phosphate. Screened by a lot of experiments, tin hydrogen phosphate is preferably a solid phase extraction adsorption medium for heavy metal ion enrichment and trace determination, the cost is lower, the adsorption capacity is great, an enrichment factor is high, enrichment performance is stable, multiple types of heavy metal ions (including lead ion, copper ion, arsenic, zinc and the like) can be enriched at the same time, the detection sensitivity and accuracy of the heavy metal ions in the marine food product can be improved, and tin hydrogenphosphate is insoluble in water and organic solvents, is resistant to strong acid and certain alkalinity, is high in chemical stability, can be reused, and has important social and economic effects.

Owner:HUAIHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

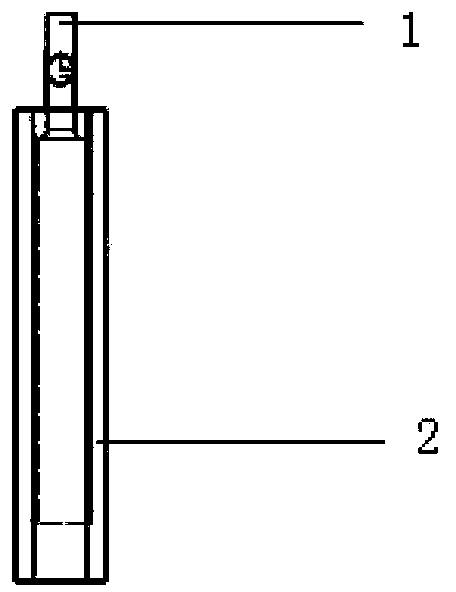

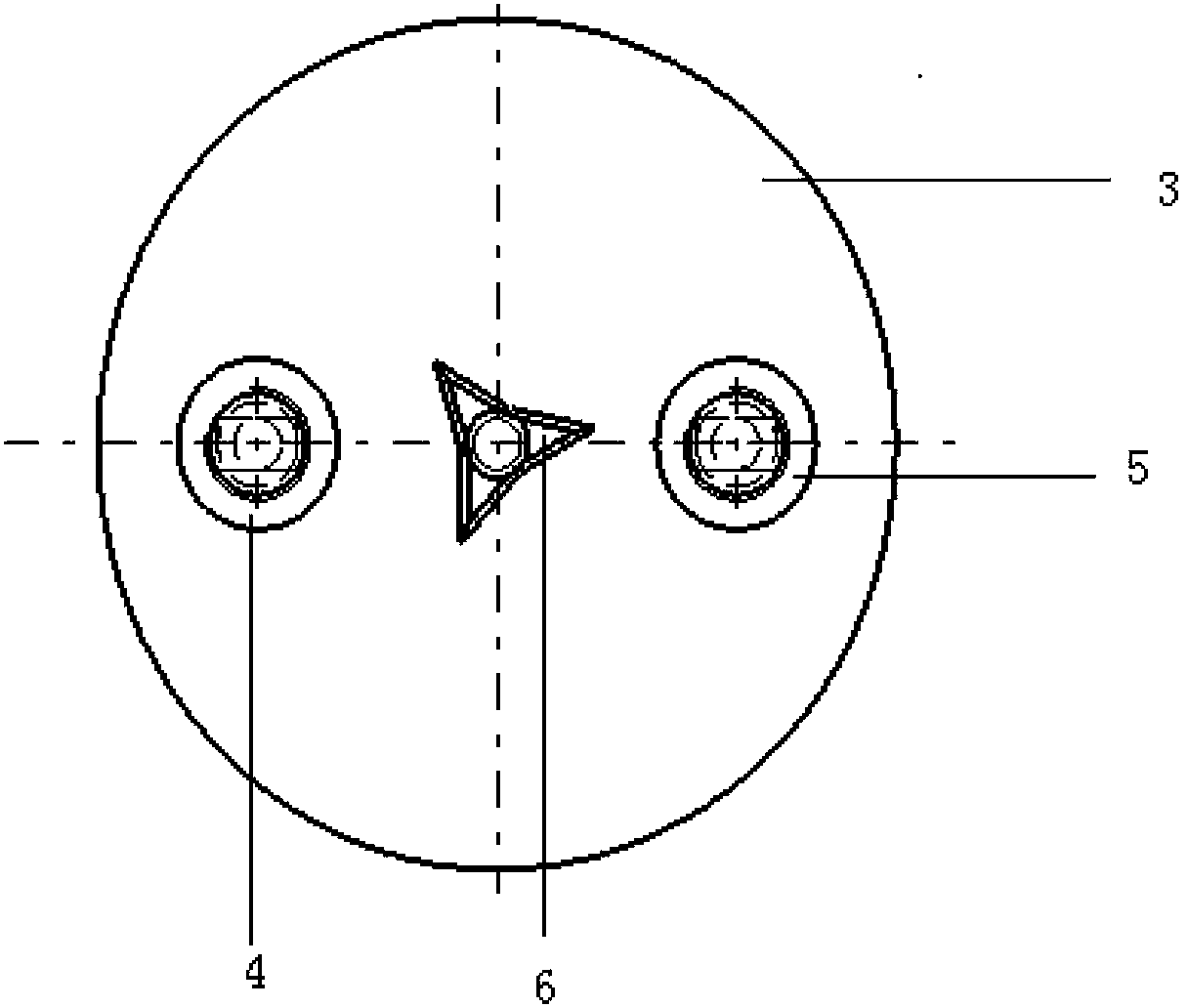

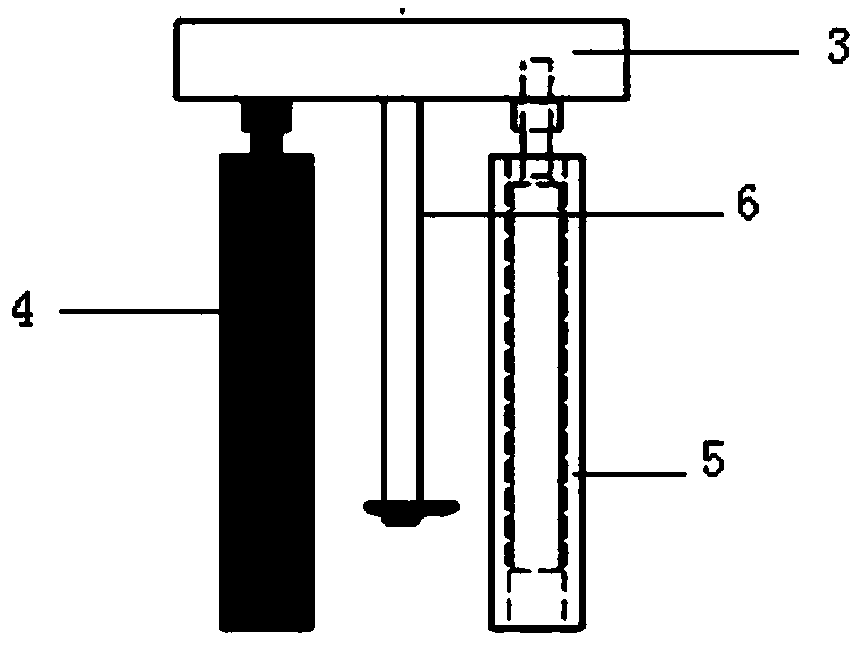

![A blue or/and green light-emitting mononuclear copper[i] complex material A blue or/and green light-emitting mononuclear copper[i] complex material](https://images-eureka.patsnap.com/patent_img/fb5da46b-bb7d-4432-929e-e5a1e5b199ab/HDA0000698426210000011.png)

![A blue or/and green light-emitting mononuclear copper[i] complex material A blue or/and green light-emitting mononuclear copper[i] complex material](https://images-eureka.patsnap.com/patent_img/fb5da46b-bb7d-4432-929e-e5a1e5b199ab/HDA0000698426210000012.png)

![A blue or/and green light-emitting mononuclear copper[i] complex material A blue or/and green light-emitting mononuclear copper[i] complex material](https://images-eureka.patsnap.com/patent_img/fb5da46b-bb7d-4432-929e-e5a1e5b199ab/HDA0000698426210000021.png)