Chemical silver plating solution for printed circuit board and preparation method of circuit board

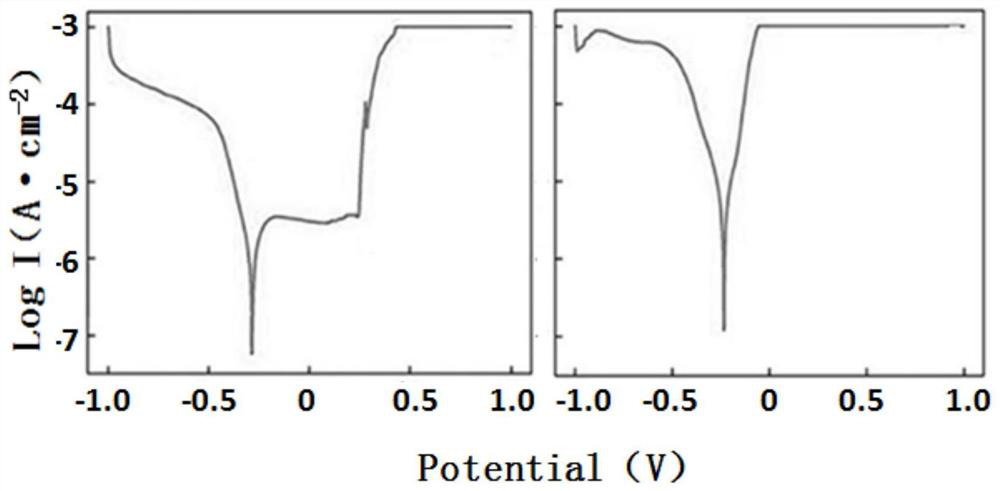

A printed circuit board, chemical silver plating technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit secondary treatment, etc., can solve the problem of copper layer over-corrosion, etc., achieve silver layer density, good stability, and avoid strong oxidation The effect of the influence of the sexual environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

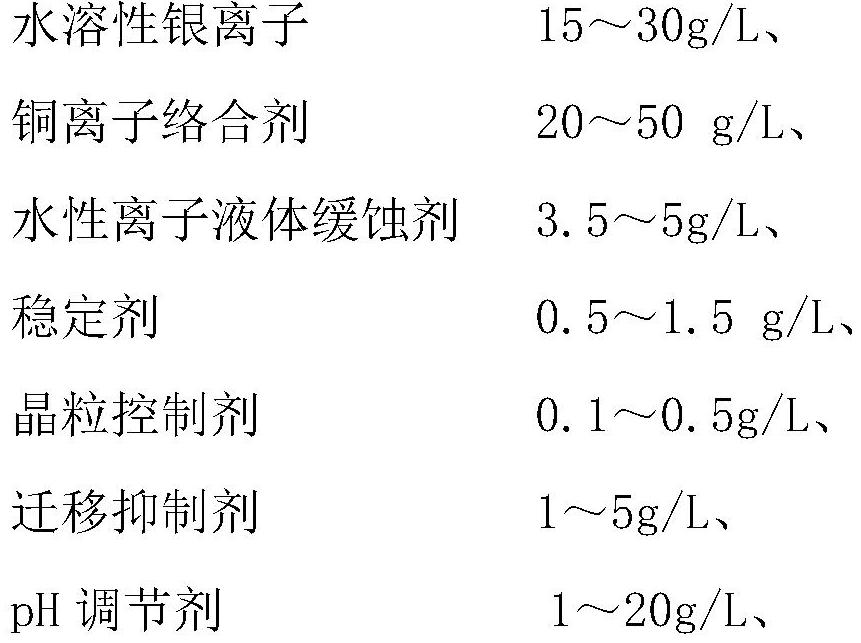

Embodiment 1

[0048] An electroless silver plating solution for printed circuit boards, comprising the following components: 20g / L of silver chloride, 30g / L of acetyl lactol, 4g / L of aqueous ionic liquid corrosion inhibitor, 1g / L of 2,2'-bipyridine , polyoxyethylene sorbitan monopalmitate 0.2g / L, hexadecanoic acid 2g / L, dilute hydrochloric acid 8.9g / L, deionized water balance, pH value 5.9.

[0049] The aqueous ionic liquid corrosion inhibitor is selected from

[0050] Wherein R1, R2, R3, R4 are all methyl groups. C - for chloride ions.

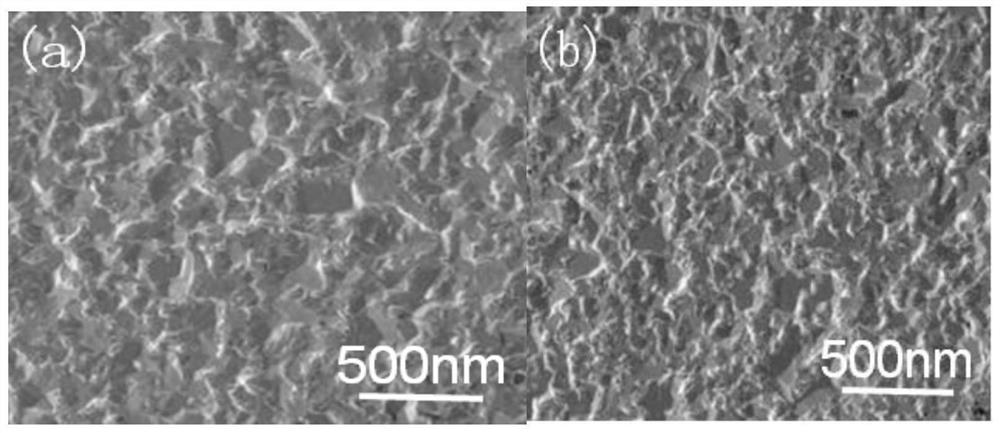

[0051] A method for preparing a printed circuit board, comprising the following steps: (1) providing a ceramic substrate, cleaning and roughening; (2) depositing metallic copper by magnetron sputtering as a seed layer with a thickness of 466nm; wherein process parameters: high-purity metal Copper is used as the target, the flow rate of high-purity argon gas is 160 sccm, the working pressure is 2.3Pa, the substrate temperature is 350°C, the sputtering ...

Embodiment 2

[0053] An electroless silver plating solution for printed circuit boards, comprising the following components: silver sulfamate 25g / L, acetyllide urea 40g / L, aqueous ionic liquid corrosion inhibitor 4.5g / L, 2-mercaptobenzothiazole 1.2g / L, polyoxyethylene (20) sorbitan monolaurate 0.4g / L, oleic acid 4g / L, acetic acid 10.5g / L, deionized water balance, pH value 6.1. The aqueous ionic liquid corrosion inhibitor is selected from

[0054] Wherein R1, R2, R3, R4 are ethyl. C - For the benzenesulfonate ion.

[0055] A method for preparing a printed circuit board, comprising the following steps: (1) providing a ceramic substrate, cleaning and roughening; (2) depositing metal copper by magnetron sputtering as a seed layer, with a thickness of 550nm; wherein process parameters: high-purity metal Copper is used as the target, the flow rate of high-purity argon gas is 250 sccm, the working pressure is 4.8Pa, the substrate temperature is 400°C, the sputtering power is 400W, the distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com