Method for mineralizing and fixing heavy metals in tailings by using lysinibacillus fusiformis and quicklime

A lysine bacillus, spindle-shaped technology, applied in the field of environmental engineering, can solve problems such as heavy metal pollution in tailings, achieve the effect of reducing the possibility of environmental pollution, wide sources, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

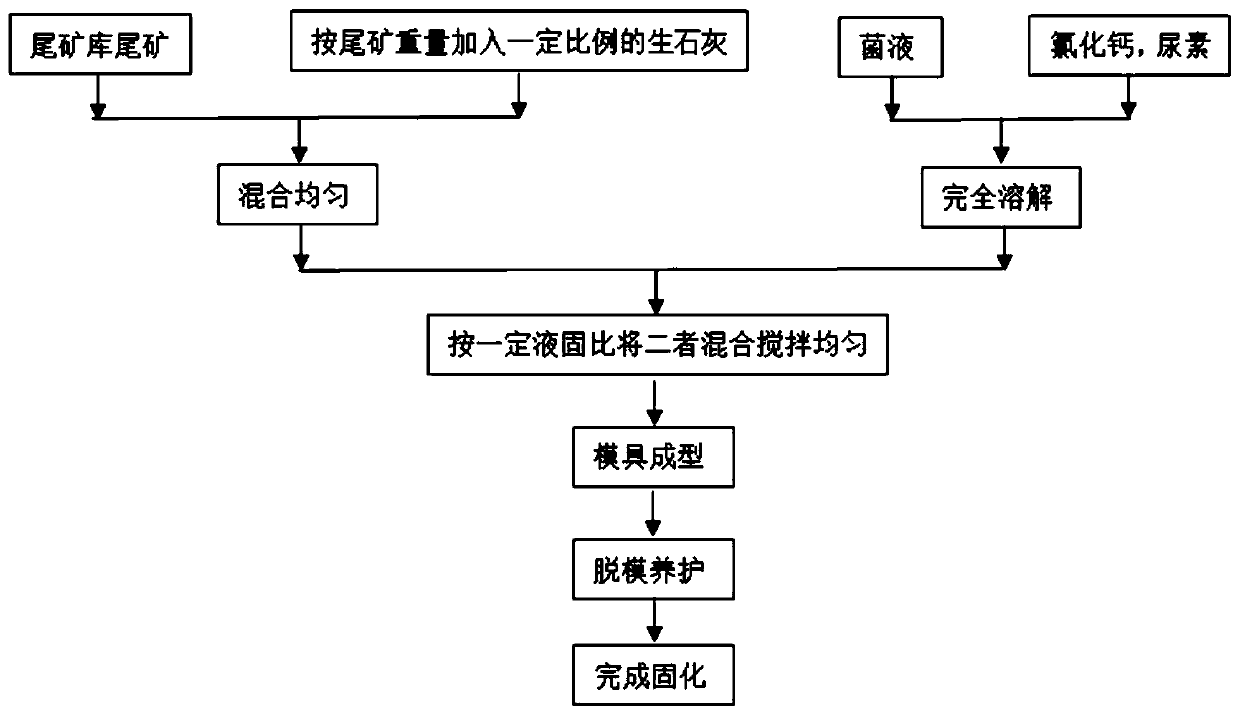

Method used

Image

Examples

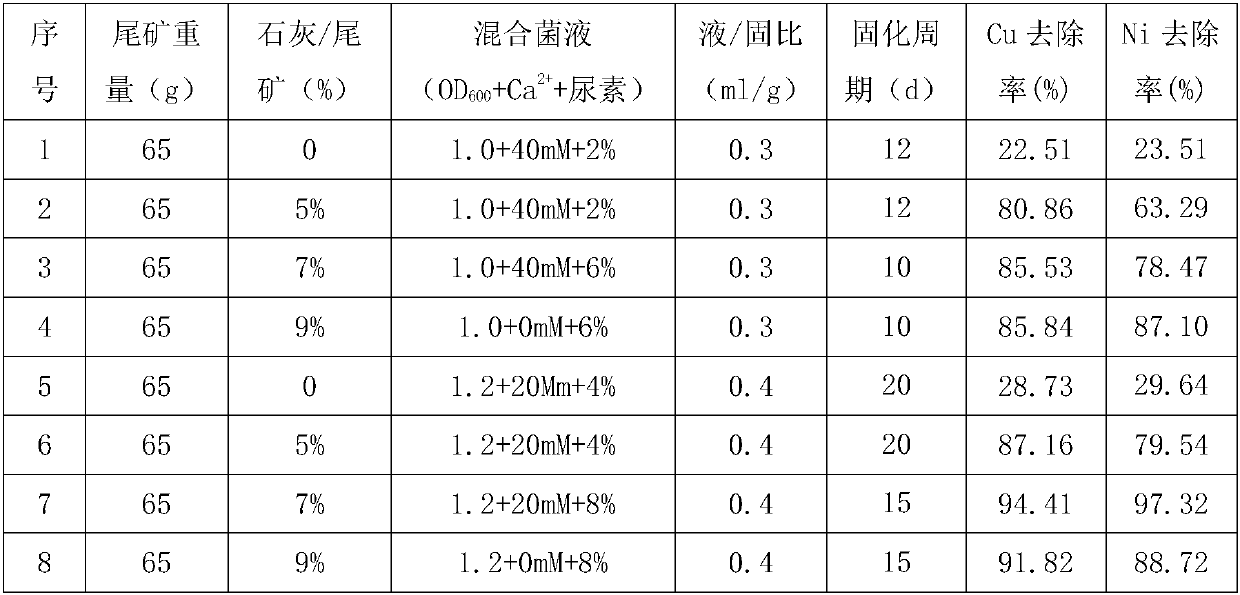

Embodiment 1

[0039] Spindle-shaped lysine bacillus and quicklime are applied to the method for fixing heavy metals in copper-nickel tailings, as follows: the first step: use the nutrient broth medium purchased from the website of Sinopharm Chemical Reagent, and the configuration concentration is 0.018 g / ml liquid medium, sterilized at 121°C for 30 minutes and cooled, then cultured the purchased spindle-shaped lysine bacillus in a shaker at 25°C and 100 rpm for 10 hours to activate, and the activated spindle-shaped lysine Acidic acid bacillus was inoculated into the culture medium and placed on a shaker with a rotation speed of 100rpm to expand culture for 1 day, and the microbial concentration was obtained as OD 600 =1.0-2.0 bacteria solution, the culture condition is temperature 20°C, use 0.018g / ml nutrient broth medium to dilute the bacteria solution concentration to OD before curing tailings 600 =1.0 or 1.2; second step: take by weighing 65g of copper-nickel tailings sample, for every 6...

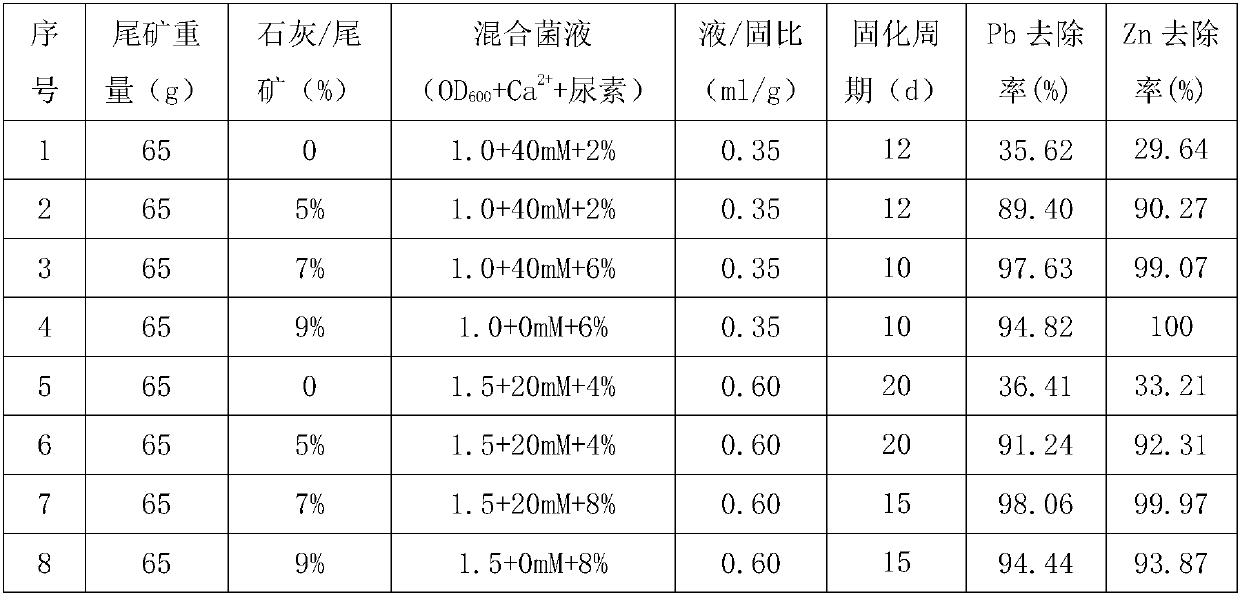

Embodiment 2

[0044] Spindle-shaped lysine bacillus and quicklime are applied to the method for fixing heavy metals in gold tailings, as follows: the first step: use the nutrient broth medium purchased from the website of Sinopharm Chemical Reagent, and the configuration concentration is 0.018g / ml of liquid medium, sterilized at 121°C for 30 minutes and cooled, then cultured the purchased spindle-shaped lysine bacillus in a shaker at 30°C and 150 rpm for 16 hours to activate, and the activated spindle-shaped lysine Acidobacillus was inoculated into the culture medium and placed on a shaker with a rotation speed of 150rpm to expand the culture for 3 days, and the microbial concentration was obtained as OD 600 =1.0-2.0 bacteria solution, culture condition is temperature 30°C, use 0.018g / ml nutrient broth medium to dilute the concentration of bacteria solution to OD before curing tailings 600 =1.0 or 1.5; second step: take by weighing 65g of gold tailings sample, for every 65g of tailings res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com