Soil curing agent doped with sludge incineration ash and preparation method thereof

A soil solidifying agent and sludge incineration technology, applied in the field of solidifying agents, can solve problems such as serious greenhouse effect, and achieve the effect of reducing carbon dioxide emissions and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use PO42.5 cement, S95 slag powder, industrial by-product gypsum and sludge incineration ash as raw materials, and make ingredients according to Table 1. Among them, industrial by-product gypsum includes sintered dry desulfurization ash, phosphogypsum and titanium gypsum. The ratio of by-product gypsum converted to dry basis.

[0036] In this embodiment, a solidifying agent is used to reinforce the silt soil. The dosage of the curing agent is 12%, and the water-binder ratio (that is, the percentage of water in the total amount of the curing agent and the silt soil) is 0.5.

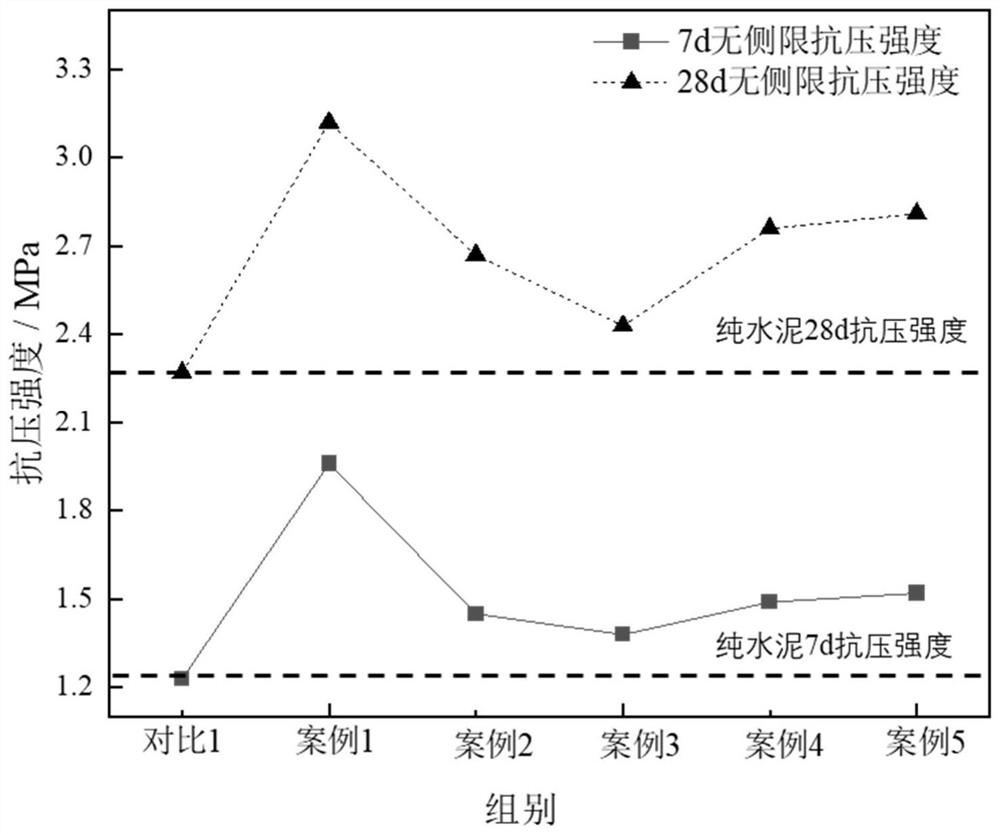

[0037] The 7d unconfined compressive strength and 28d unconfined compressive strength were tested according to the unconfined compressive strength test method of B.2 in JGJ / T 233-2011; the test results are as follows:

[0038]Table 1: Test mix ratio (%) and soil unconfined compressive strength of solidifying agent reinforced soil mixed with sludge incineration ash

[0039]

[0040]

[0041] T...

Embodiment 2

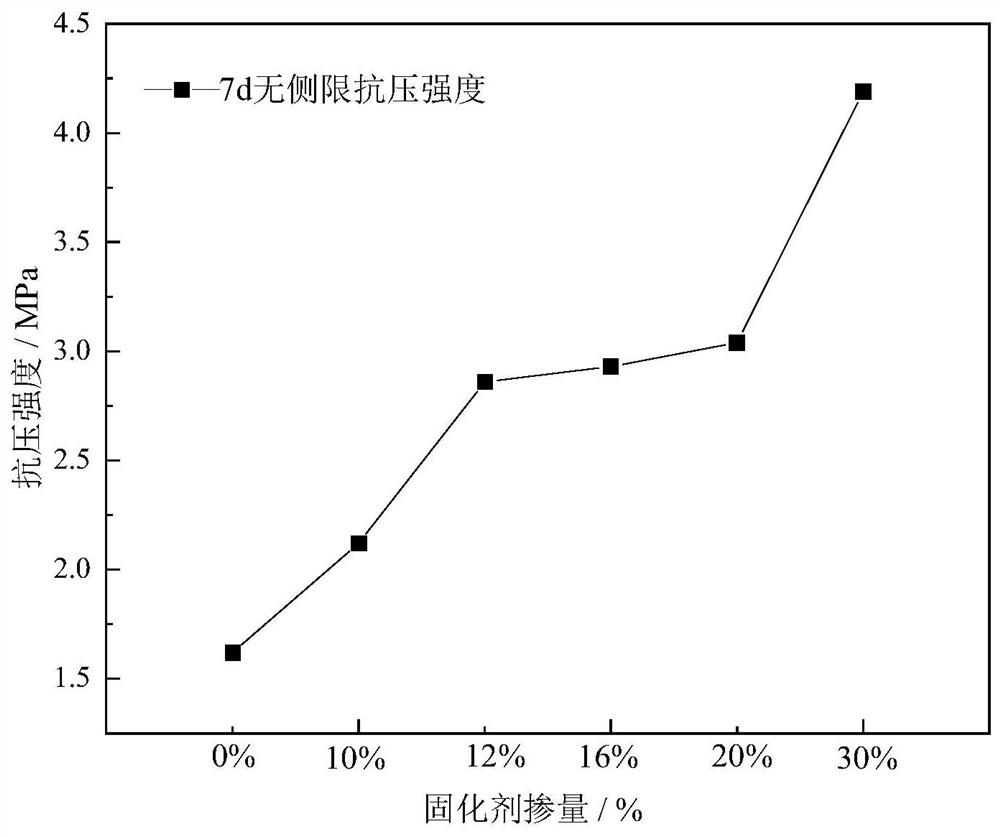

[0047] In this embodiment, the soil solidifying agent mixed with sludge incineration ash is used to strengthen the soft foundation, and the specific steps are as follows:

[0048] (1) Sludge incineration ash is first pretreated by ball milling, followed by 45 μm negative pressure sieve analysis method in GB / T 1345. The sieve analysis time is 3 minutes, and the fineness of sludge incineration ash is 11.2%.

[0049] Among them, the specific steps of the negative pressure sieve analysis method in GB / T 1345 include: before the sieve analysis test, a 45 μm negative pressure sieve should be placed on the sieve seat, the sieve cover should be covered, the power supply should be connected, the control system should be checked, and the negative pressure should be adjusted to Within the range of 4000Pa~6000Pa; Weigh the sample to an accuracy of 0.01g, place it in a clean negative pressure sieve, put it on the sieve seat, cover the sieve cover, turn on the power, start the sieve analyzer ...

Embodiment 3

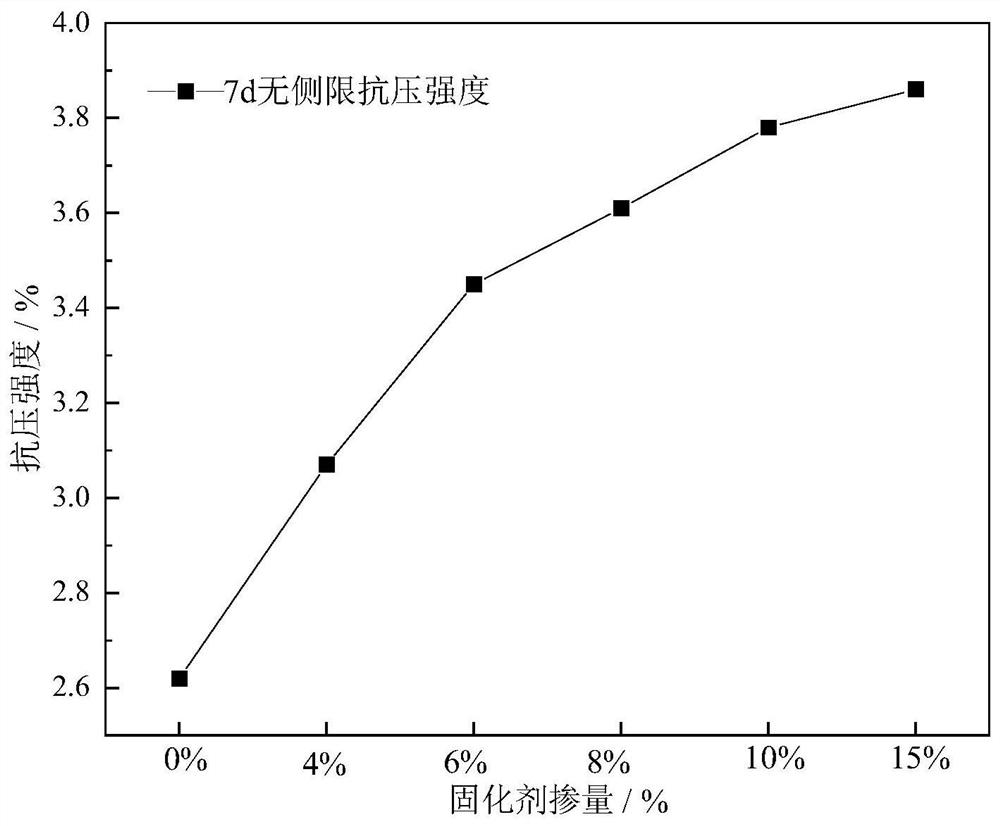

[0067] In this embodiment, the solidifying agent mixed with sludge incineration ash is used instead of cement to strengthen the soil roadbed, and the specific steps are as follows:

[0068] (1) According to the 45μm negative pressure sieve analysis method in GB / T 1345, the sieve analysis time is 3min, and the fineness of the obtained sludge incineration ash is 30.2%. After testing, its heavy metal leaching concentration, dioxin and other safety The indicators are qualified;

[0069] (2) The selected industrial by-product gypsum is a by-product of phosphate fertilizer production, i.e. titanium gypsum, with a water content of 1.2%. After testing, the pH of titanium gypsum is 3, and adding 0.5% hydrated lime as a modifier to adjust the pH is 6~ 11.

[0070] (3) Weigh the sludge incineration ash, industrial by-product gypsum, slag powder and cement according to the mass percentage, and mix them to obtain a soil solidifying agent mixed with the sludge incineration ash.

[0071] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com