Mulberry wine with rose flavour and brewing process thereof

A technology of mulberry wine and flavor, applied in the field of wine making, to achieve good health effects, unique and elegant aroma, delicate and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

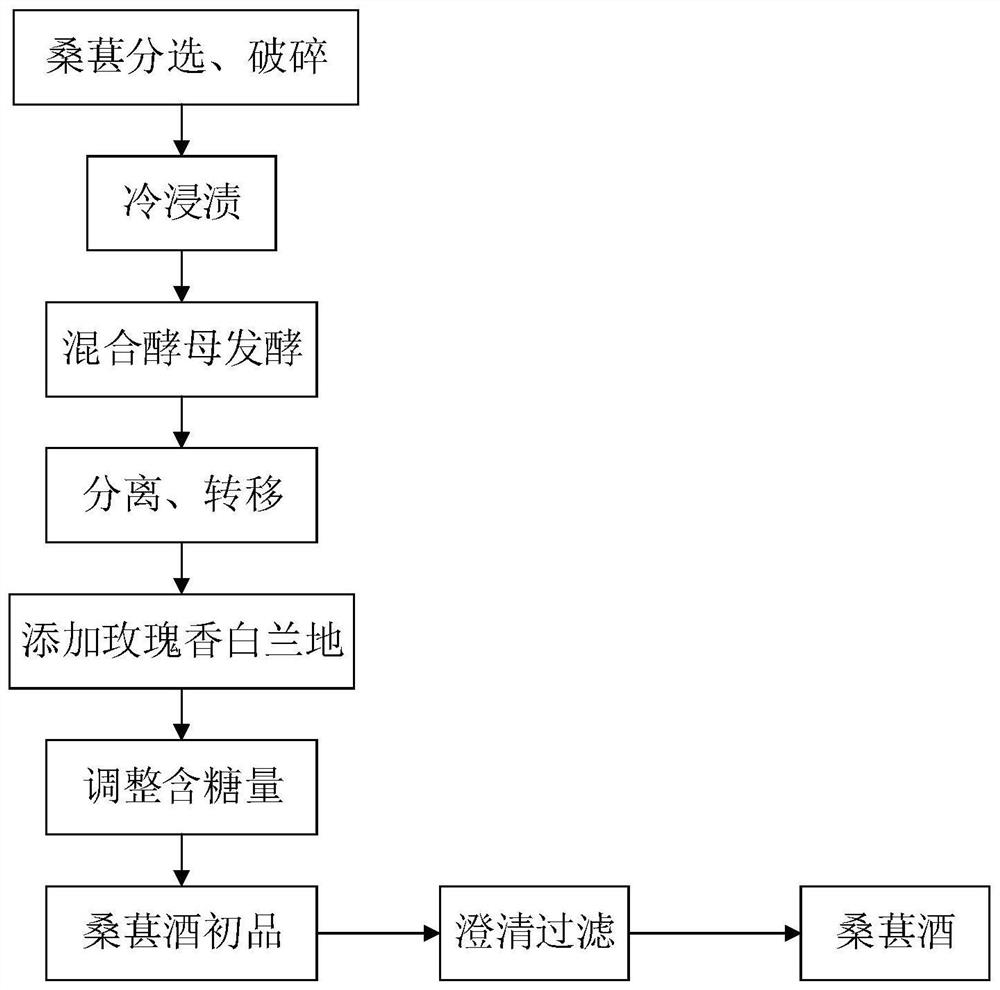

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides a kind of brewing process of mulberry wine with rose flavor, comprising the following steps:

[0045] (1) After cleaning the fermenter tank, fill it with nitrogen, put fresh mulberries into the tank (78% of the tank volume), squeeze the mulberries with a stainless steel platen while entering the tank, and crush them. After the crushing is completed, add potassium pyrosulfite to reach the sulfur dioxide content 40mg / L, after 60 minutes, add pectinase, add 180mg pectinase per liter of liquid, enzymolyze at room temperature for 8h, and obtain mulberry enzymatic hydrolyzate.

[0046] (2) Cool down the mulberry enzymatic hydrolyzate to 8°C, fill it with nitrogen and soak it in cold for 48 hours.

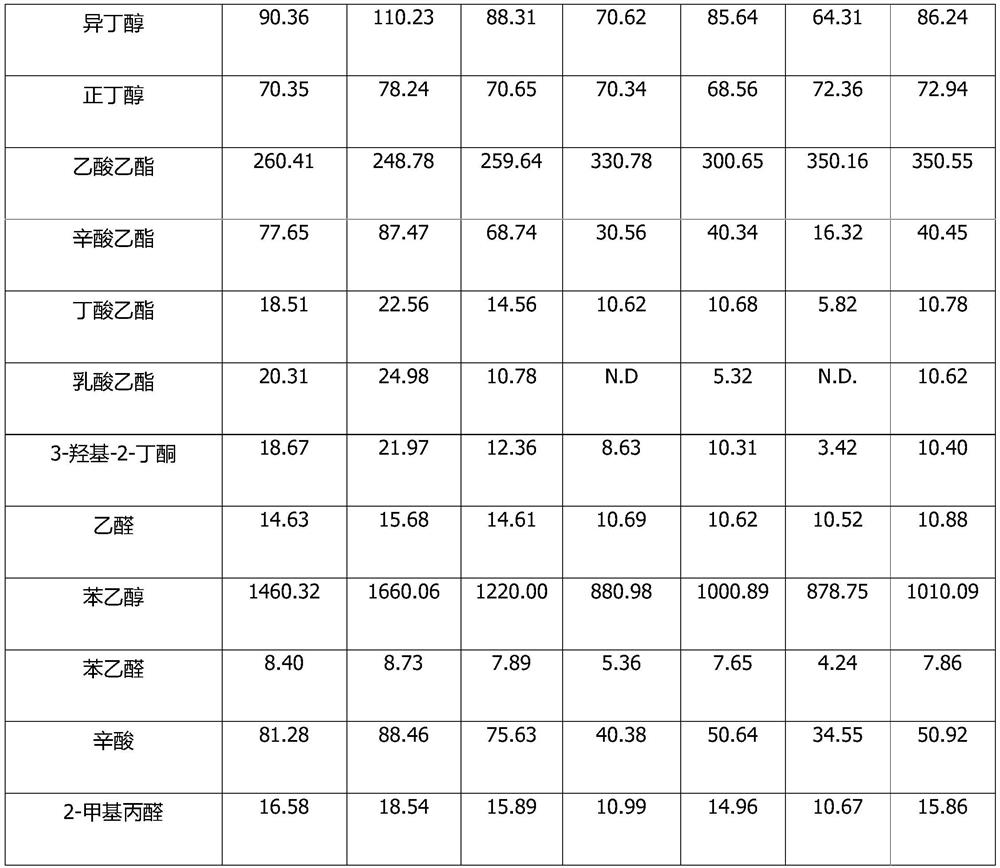

[0047] (3) Naturally warm the mulberry enzymatic solution after cold soaking to 13°C, add non-Saccharomyces cerevisiae and Angel CECA, mix well, and ferment at 18°C for 10 days. The dregs floating above the fermentation liquid were pressed into th...

Embodiment 2

[0052] The present embodiment provides a kind of brewing process of mulberry wine with rose flavor, comprising the following steps:

[0053] (1) After cleaning the fermenter tank, fill it with nitrogen gas, put fresh mulberries into the tank (79% of the tank volume), squeeze the mulberries with a stainless steel platen while entering the tank, and crush them. After the crushing is completed, add potassium pyrosulfite to the sulfur dioxide content 50mg / L, after 70 minutes, add pectinase, add 200mg pectinase per liter of liquid, enzymolyze at room temperature for 9 hours, and obtain mulberry enzymatic hydrolyzate.

[0054] (2) The temperature of the mulberry enzymatic hydrolysis solution was lowered to 9° C., filled with nitrogen, and cold soaked for 60 hours.

[0055] (3) The mulberry enzymatic solution after cold soaking was naturally warmed to 11°C, and the non-Saccharomyces cerevisiae combination was added first, and the addition amount was 1g / L. The mass ratio of Hansenula...

Embodiment 3

[0060] The present embodiment provides a kind of brewing process of mulberry wine with rose flavor, comprising the following steps:

[0061] (1) After cleaning the fermenter tank, fill it with nitrogen, put fresh mulberries into the tank (78% of the tank volume), squeeze the mulberries with a stainless steel platen while entering the tank, and crush them. After the crushing is completed, add potassium pyrosulfite to reach the sulfur dioxide content 60mg / L, after 90 minutes, add pectinase, add 220mg pectinase per liter of liquid, enzymolyze at room temperature for 10h, and obtain mulberry enzymatic hydrolyzate.

[0062] (2) Cool the mulberry enzymatic hydrolyzate to 10°C, fill it with nitrogen and soak it in cold for 72 hours.

[0063] (3) The mulberry enzymatic solution after cold soaking was naturally warmed to 15°C, Angel CECA was added first, the addition amount was 2.2g / L, and the non-Saccharomyces cerevisiae combination was added after 25h, the addition amount was 1.2g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com