Heat setting machine with intelligent oil control system

A technology of oil control system and heat setting machine, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve the problems of lowering product quality, easily damaging the surface of fabrics, and easily causing fire hazards, etc., so as to reduce energy consumption, The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

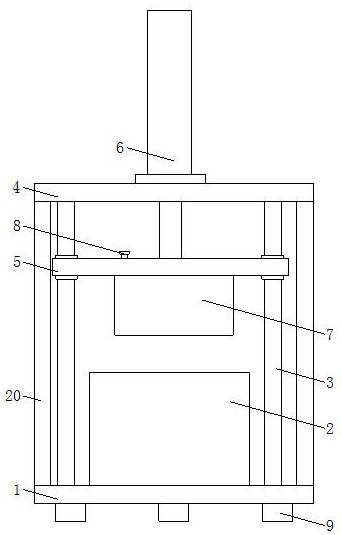

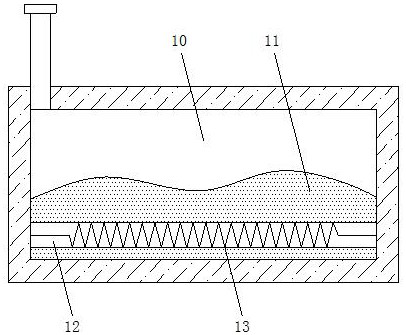

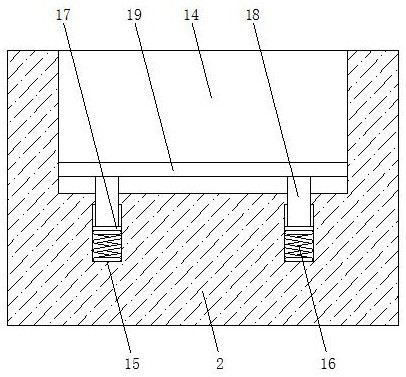

[0018] like Figure 1-3 As shown, the present invention provides a technical solution:

[0019] A heat setting machine with a smart control system, including the bottom plate 1, the bottom of the bottom plate 1 fixes a foot pad 9, and the number of foot pads 9 is five, and the five foot pads 9 are disposed in the four corners and middle portions of the bottom plate 1. The five foot pads 9 provide support for the bottom plate, and can also prevent the heat and fixing machine from moving, the upper surface of the bottom plate 1 is fixedly mounted, and the upper surface of the bottom plate 1 is fixedly connected to the guide column on both sides of the lower block 2. 3, the upper surface of the bottom plate 1 is fixedly connected to the support post 20 on the side of the guide post 3, and the top portion of the support post 20 is fixedly connected to the top plate 4, the central portion of the top plate 4 is fixedly mounted with a hydraulic cylinder 6, hydraulic cylinder 6 The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com