Radial diffusion double-layer sound insulation ABS plate

A double-layer, sound-blocking technology, applied in the direction of sound insulation, insulation layer, floor, etc., can solve the problems of poor space privacy, affecting the scope of application, etc., and achieve the effect of reducing the diffusion speed, improving the sound insulation effect, and being less prone to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

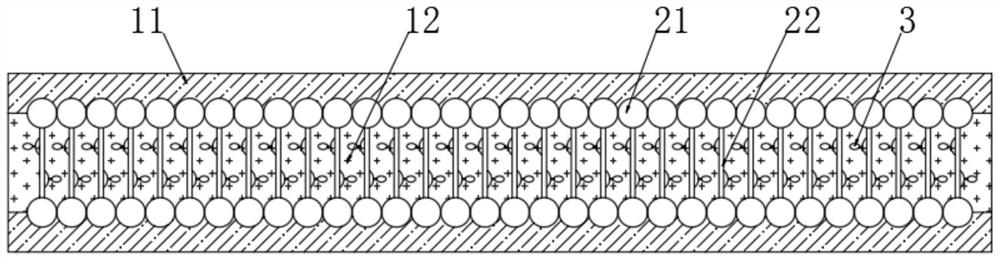

[0042] see figure 1 , a radially diffused double-layer sound-insulating ABS board, comprising two ABS boards 11 and a sound-insulating interlayer 12 fixedly inlaid between the two ABS boards 11, the sound-insulating interlayer 12 is fixedly inlaid with a plurality of uniform and distributed radial guides Sound bar, the two ends of the radial sound guide bar are respectively extended and inlaid on the ends of the two ABS boards 11 that are close to each other.

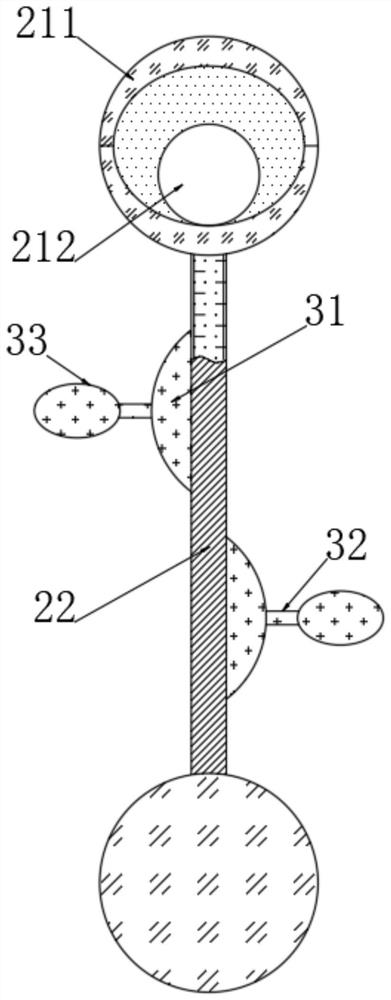

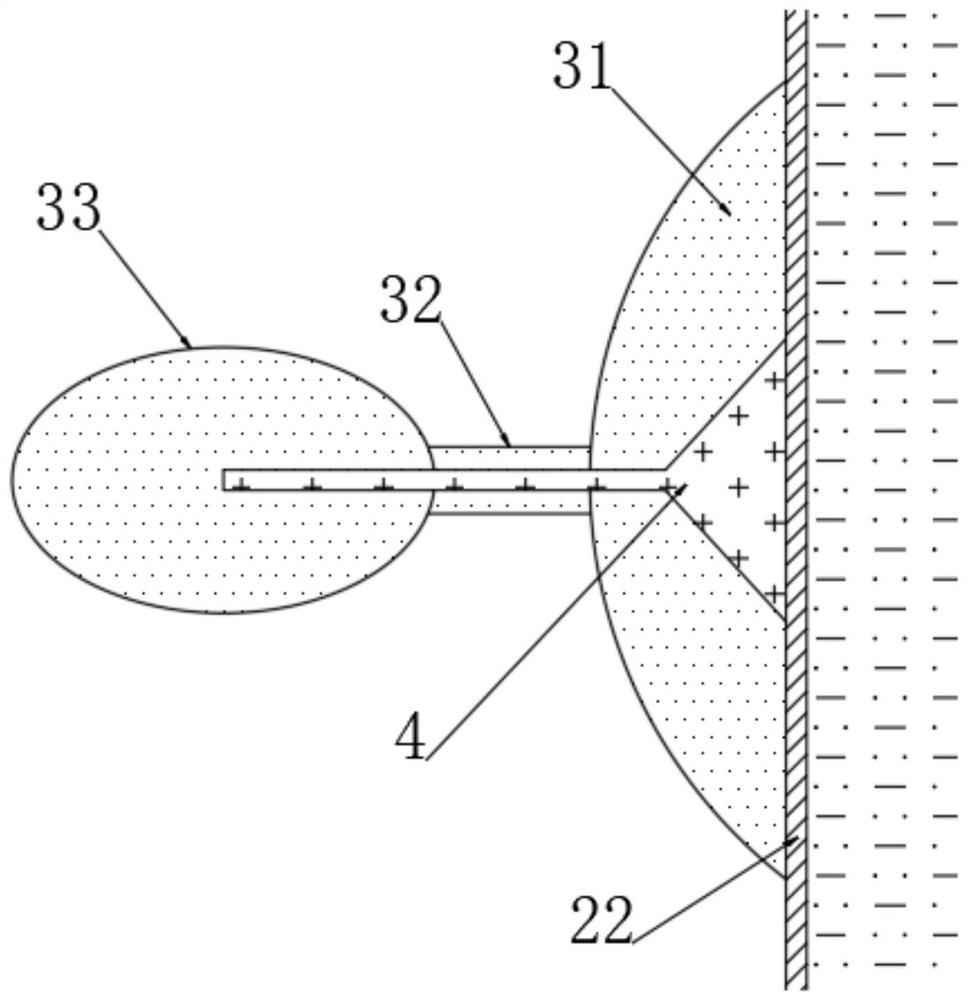

[0043] see figure 2 , the radial sound guide rod includes two sound-damping balloons 21 and a sound-damping rod 22 connected between the two sound-damping balloons 21, and the outer end of the sound-damping rod 22 is fixedly connected with a plurality of evenly distributed sound-damping gas sticks 3, The sound balloon 21 includes two sound-proof hemispheres 211 fixedly connected to each other and a built-in limit ball 212 placed between the two sound-proof hemispheres 211, and the interior of the two sound-proof hemis...

Embodiment 2

[0048] see Image 6 , a high-resilience balloon is placed in the sound-proof balloon 21, and the high-resilience balloon includes an outer ventilating spherical shell 61, a positioning inner core 62 positioned at the center of the outer ventilating spherical shell 61, and a plurality of positioning cores connected to the inner wall of the outer ventilating spherical shell 61 and the positioning inner core. The support rod 63 between the outer surfaces of the core 62 and the outer ventilating balloon shell 61 are elastic multi-hole structures, so that the inert gas in the sound-proof balloon 21 can penetrate into the high-resilience balloon, and the support rod 63 is made of high-toughness material As a result, in this embodiment, the high-resilience balloon can replace the built-in limit ball 212 in Embodiment 1, and the other structures are consistent with Embodiment 1. , when the high-resilience balloon is squeezed to a certain extent, the inert gas inside is squeezed out. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com