Centrifugal hydrogen circulating pump

A circulating pump and centrifugal technology, which is applied in the field of centrifugal hydrogen circulating pumps, can solve the problems of poor sealing, noise, etc., and achieve the effects of small voltage difference, easy uniform diffusion, and prevention of obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

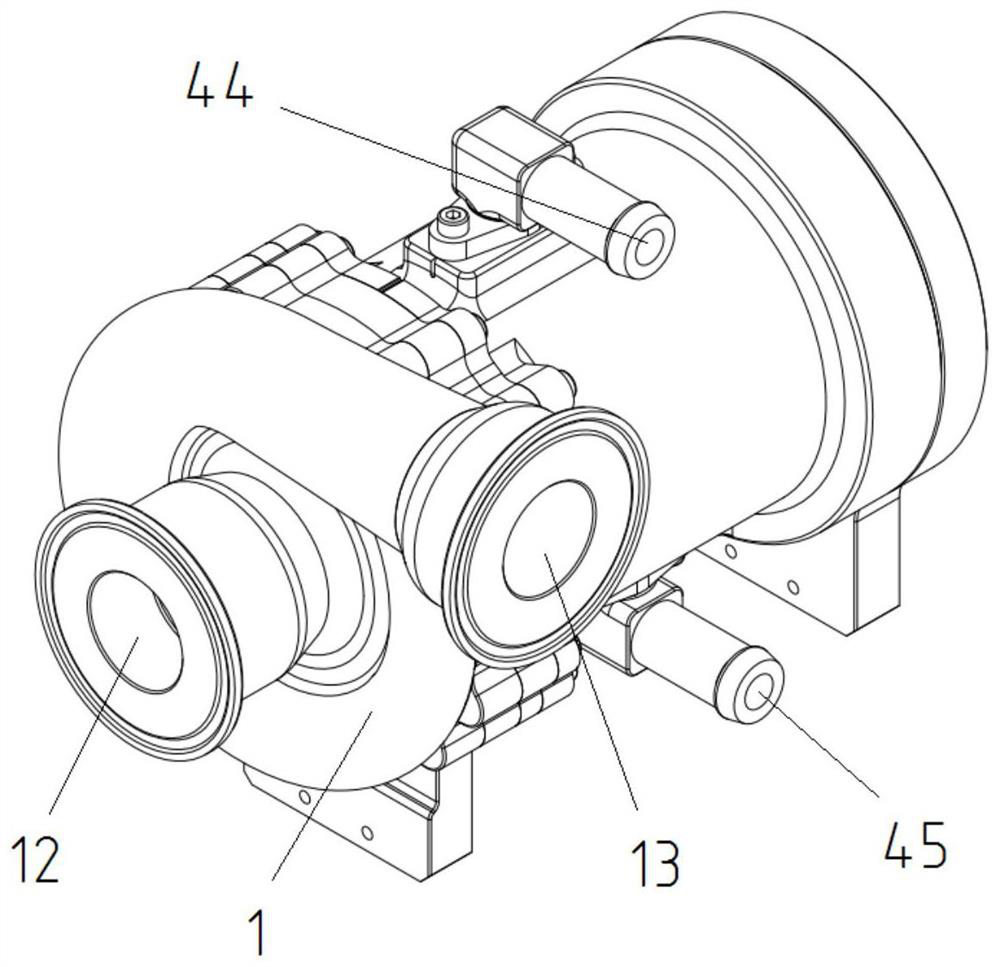

[0033] In order to facilitate understanding of the present invention, below in conjunction with Figure 1-7 And specific examples, the present invention is described in more detail.

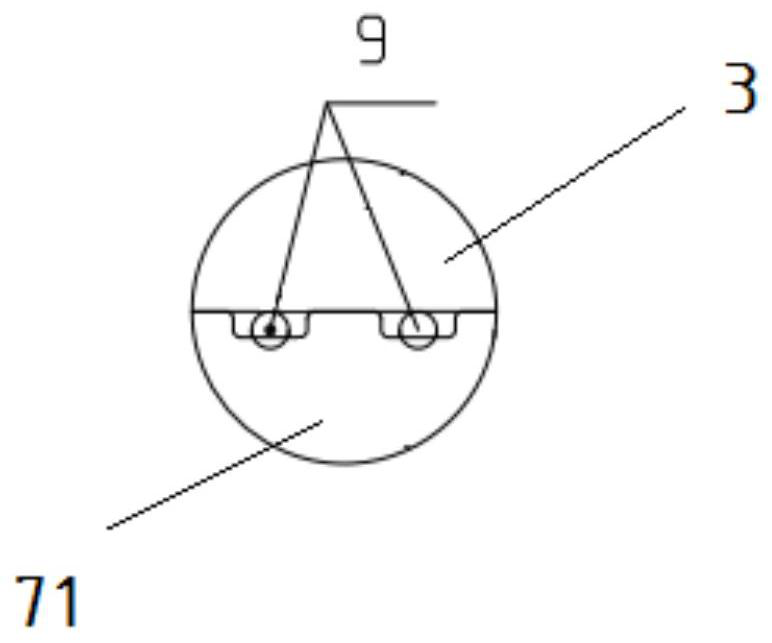

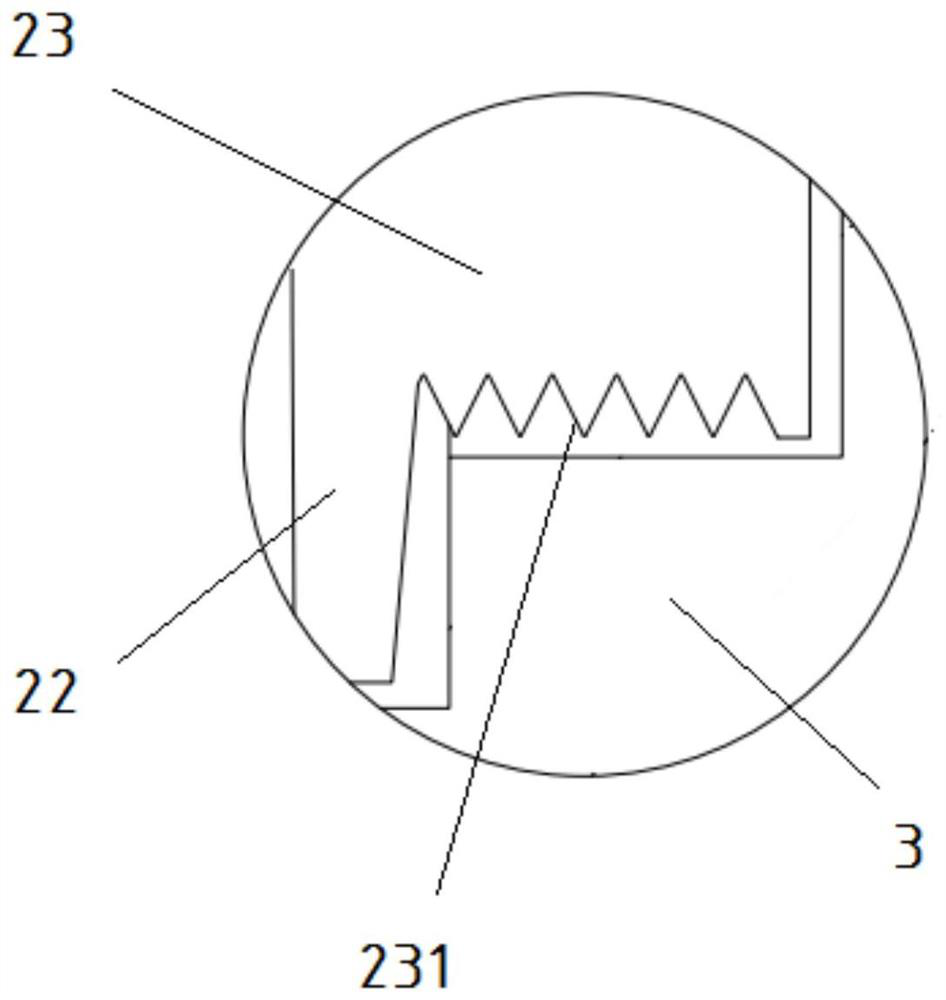

[0034] A centrifugal hydrogen circulation pump, such as Figure 1-4 As shown, it includes a volute 1, an impeller 2, an adapter seat 3, a pump casing 4, and a motor stator 5 and a motor rotor 6 located inside the pump casing 4; the volute 1 includes a The axial air inlet 12 and the tangential exhaust pipe 13 arranged in its circumferential direction are sealed with a sealing ring 9 (such as an O-ring) between the volute 1 and the adapter seat 3 to prevent hydrogen leakage. Driven by the rotor shaft 61, the impeller 2 accelerates and pressurizes the gas at the axial inlet 12 and then discharges it from the tangential exhaust pipe 13; the adapter seat 3 is close to the One end of the volute 1 is sequentially provided with an impeller housing hole and a bearing steel sleeve housing hole, the impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com