Process for machining reticulate pattern knurls through macro program

A macro program and process technology, applied in the field of CNC machining, can solve the problems of poor program applicability, large cutting resistance, low machining efficiency, etc., and achieve the effects of strong applicability, convenient programming, and simple equipment use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

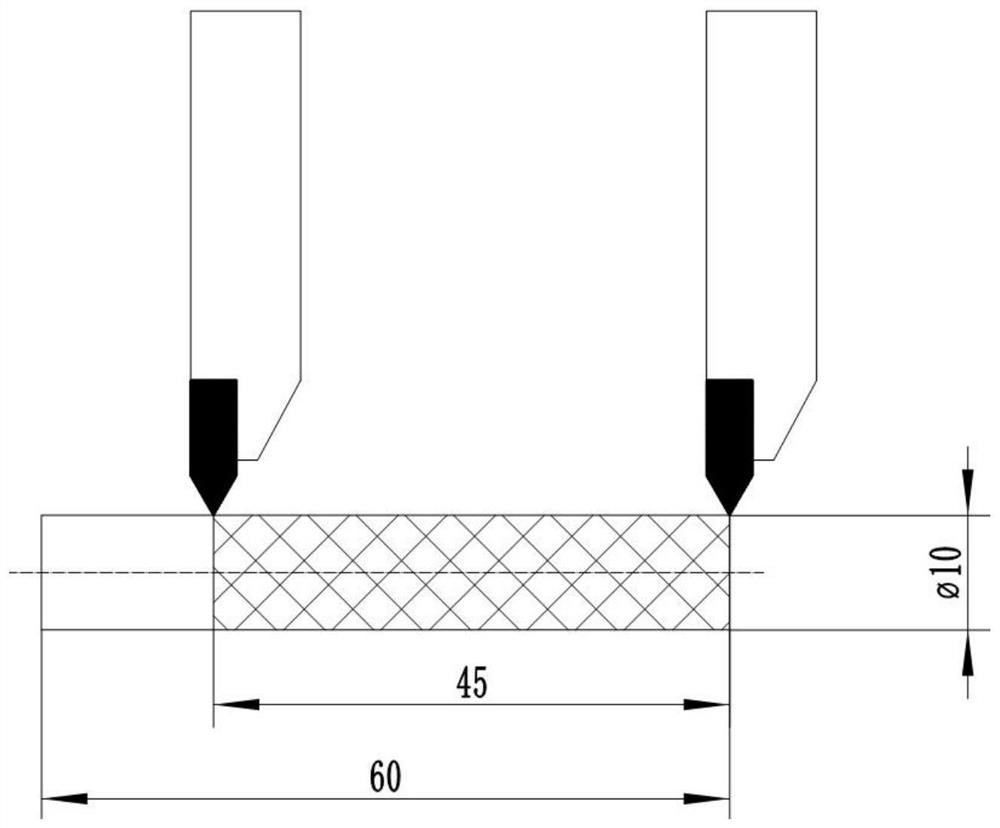

[0019] Example: such as figure 1 As shown, the present invention uses a macro program to process anilox knurling. This process includes importing the functionalized processing track into the G code, and a circle of 360 degrees. Since it starts from 0 degrees, it only needs to be indexed to 354 degrees. degree, namely Q354000, the first division: Q=0

[0020] The second division: Q=6000

[0021] The third division: Q=12000

[0022] The fourth division: Q=18000

[0023] …

[0024] The 59th indexing: Q=354000

[0025] Since #1 is assigned a value of 0 at the beginning, after the positive and negative threading, the variable self-increment #1=#1+6000 is encountered, and the value of #1 is increased by 6000, and then the condition of the parentheses in the IF statement is [ #1 is less than or equal to 354000] Then let the program jump to the above program segment, and start running from the above program segment, and then turn the thread forward and reverse (because #1 has don...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com