Rapid optimization design and evaluation method for cam five-connecting-rod mechanism

An optimized design, five-link technology, applied in design optimization/simulation, instrument, geometric CAD, etc., can solve problems such as time-consuming, cumbersome design process, and inability to know the design method, so as to reduce the difficulty of development, avoid repeated calculations, The effect of speeding up your design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

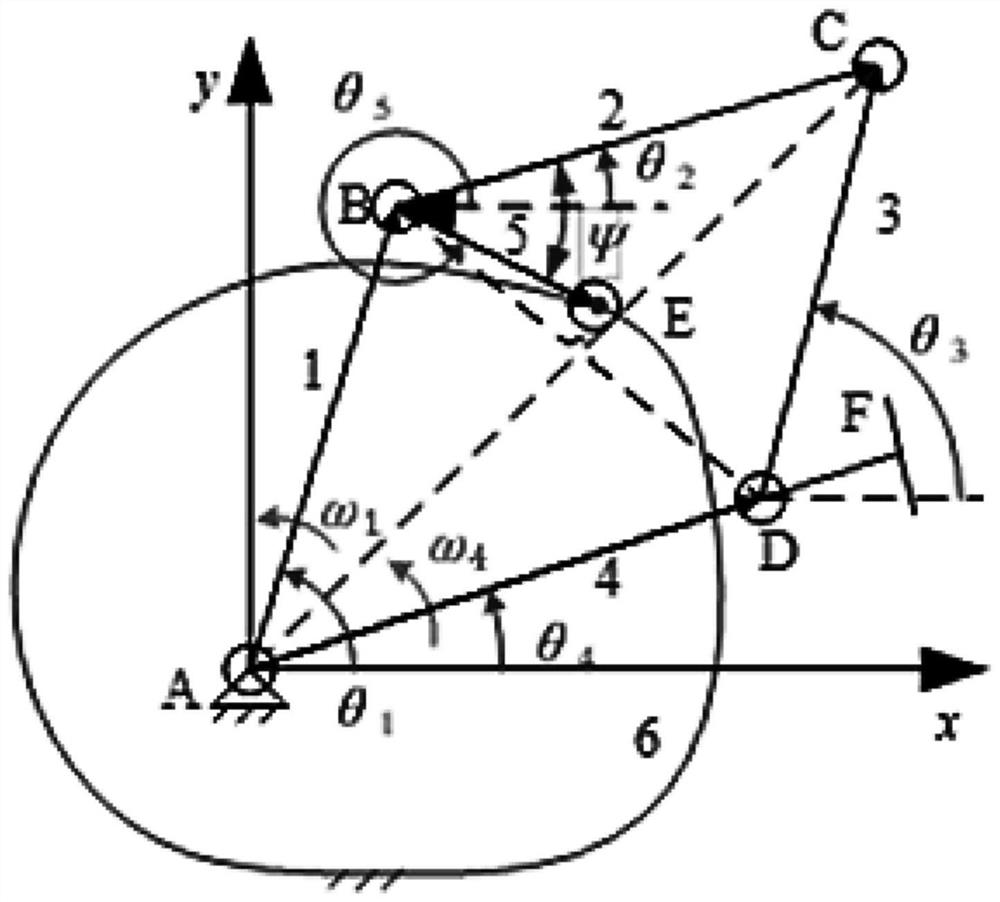

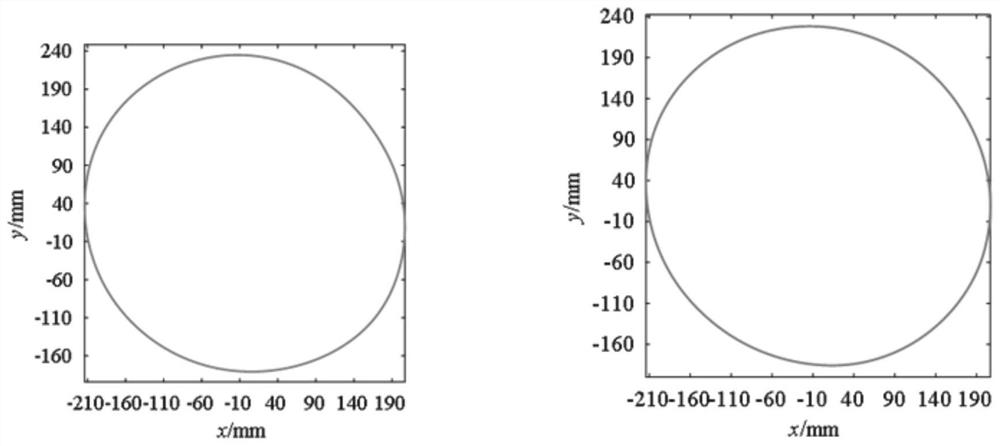

[0068] refer to Figure 1 to Figure 9 , a method for fast optimal design and evaluation of a cam five-bar linkage mechanism, comprising the following steps:

[0069]Step1: degree of freedom analysis, the degree of freedom of analyzing the cam five-bar linkage mechanism is 2;

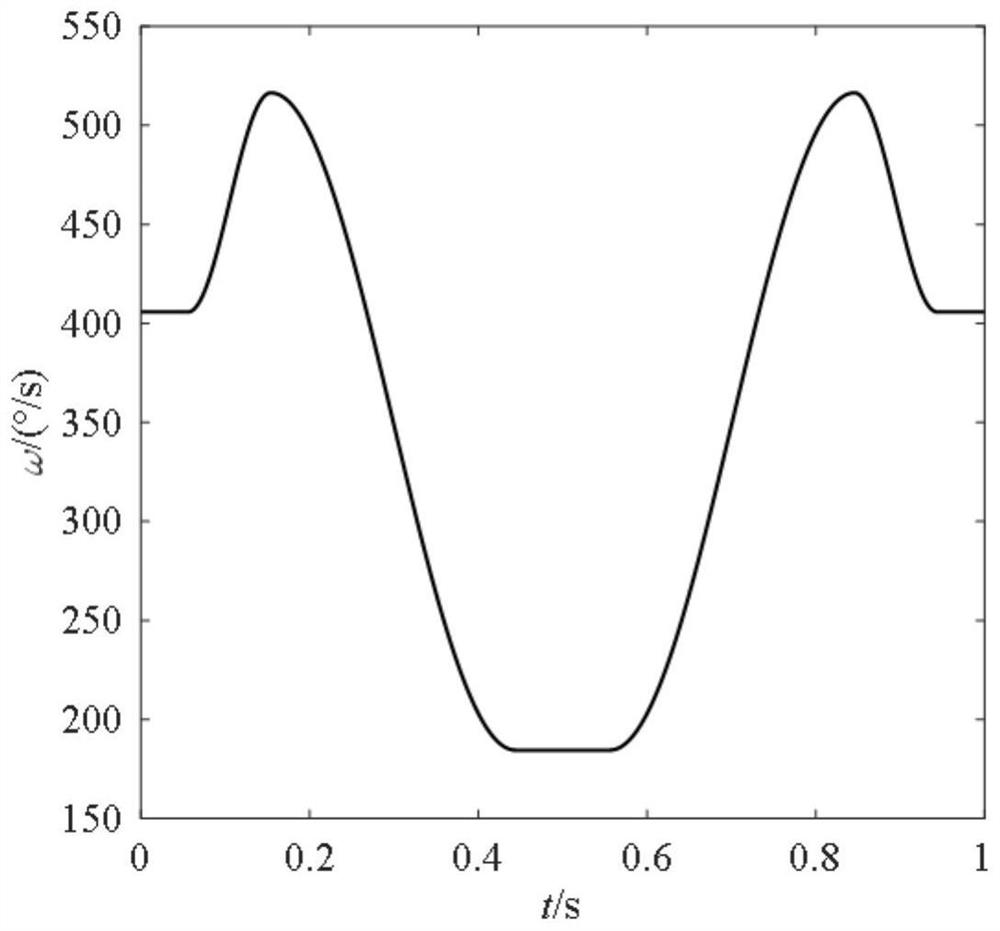

[0070] Step2: Determine the velocity curve of the output member;

[0071] Step3: Carry out mathematical modeling to cam five-bar linkage mechanism, determine the mathematical model of cam five-bar linkage mechanism;

[0072] Step4: Determine the input speed of a bar;

[0073] Step5: solve;

[0074] Step6: optimal design;

[0075] Step7: Motion accuracy reliability analysis.

[0076] Among them, in Step3, the rod lengths of the cam five-bar linkage mechanism are determined to be l 1 , l 2 , l 3 , l 4 , l 5 ;

[0077] The end points of the cam five-bar linkage mechanism are A, B, C, D, E respectively;

[0078] The angle between AB and the x-axis is θ 1 , The angle between BC and the x-axis is ...

Embodiment 2

[0116] The difference with Example 1 is:

[0117] refer to Figure 1 to Figure 9 , a method for fast optimal design and evaluation of a cam five-bar linkage mechanism, comprising the following steps:

[0118] Step1: degree of freedom analysis, the degree of freedom of analyzing the cam five-bar linkage mechanism is 2;

[0119] Step2: Determine the velocity curve of the output member;

[0120] Step3: Carry out mathematical modeling to cam five-bar linkage mechanism, determine the mathematical model of cam five-bar linkage mechanism;

[0121] Step4: Determine the input speed of a bar;

[0122] Step5: solve;

[0123] Step6: optimal design;

[0124] Step7: Motion accuracy reliability analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com