A kind of submersible motor automatic loop line

A technology of submersible motors and loop lines, which is applied in the field of submersible motor automation loop lines, can solve the problems of rough station partitions, high space layout costs, and poor equipment distribution effects, and achieve the effects of reducing production costs, facilitating partition placement, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

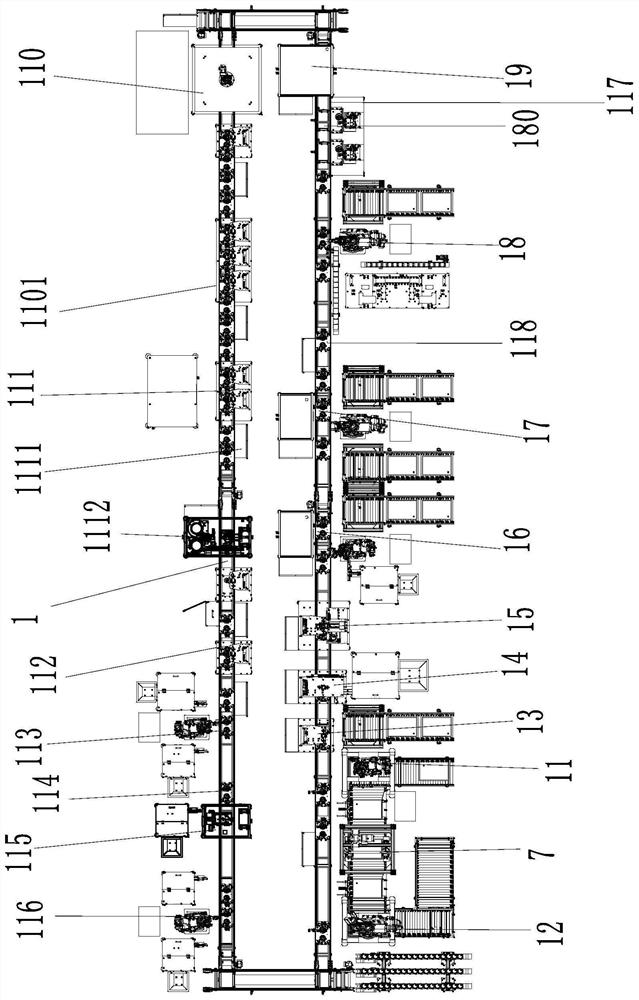

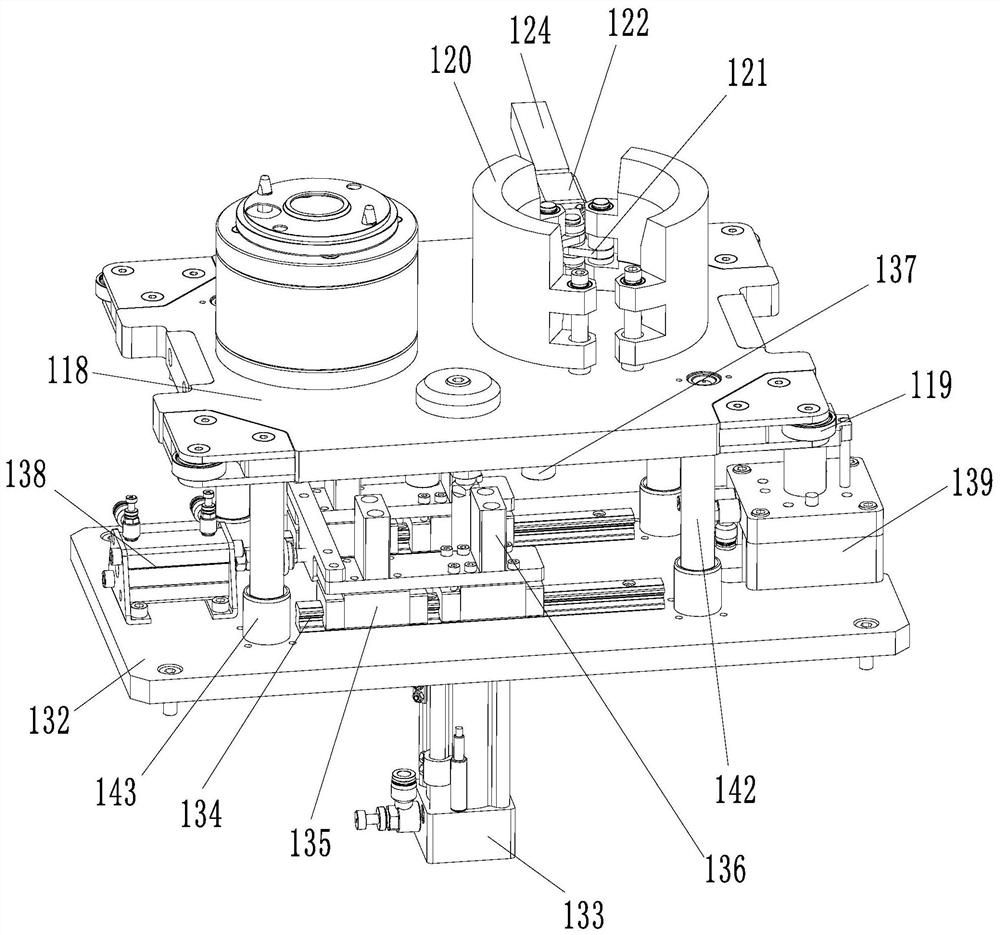

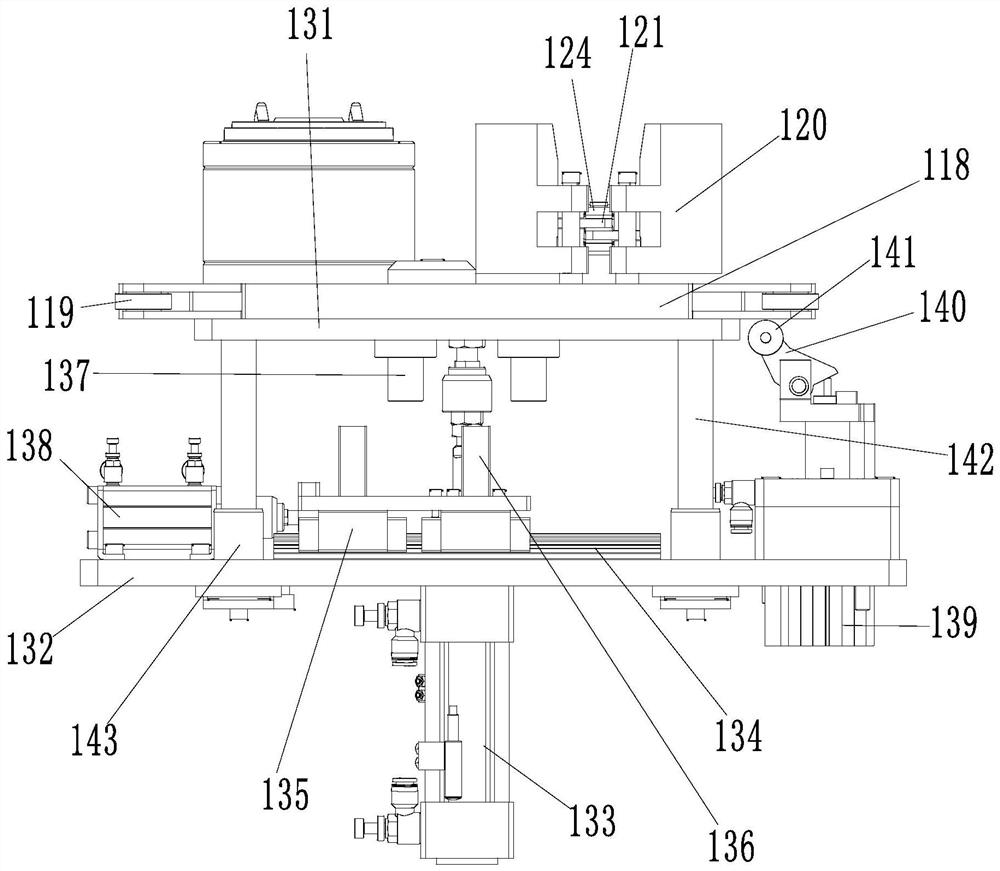

[0050] like figure 1 As shown, a submersible motor automation loop line is characterized in that it includes an assembly line 1 arranged in the loop line, and the outer side of the assembly line is provided with a feeding station 11 and a feeding station 12 that are adjacently arranged, and the feeding station includes barrel feeding. Robot and barrel feeding device, the feeding station includes motor feeding robot and motor conveying device; barrel feeding robot and motor feeding robot both use industrial robots with grippers to complete barrel feeding and motor feeding , The barrel feeding device adopts a conveyor belt, and the motor conveying device also adopts a conveyor belt. The side of the loading station facing away from the unloading station is sequentially provided with an oil bag assembly station 13, a base assembly station 14, a circlip assembly station 15, a lower bearing seat assembly station 16, and a coil assembly station along the assembly line. 17. Rotor ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com