Zinc oxide resistor disc capable of reducing residual voltage ratio and preparation method thereof

A zinc oxide resistor, residual voltage ratio technology, applied in the direction of varistor, resistor manufacturing, varistor core, etc. The effect of low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

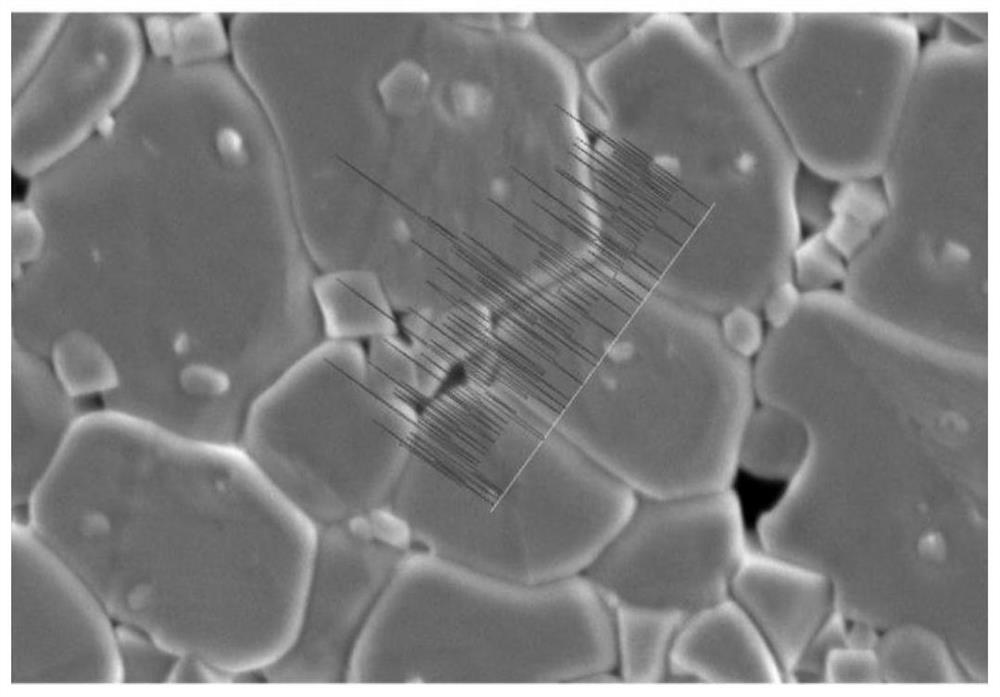

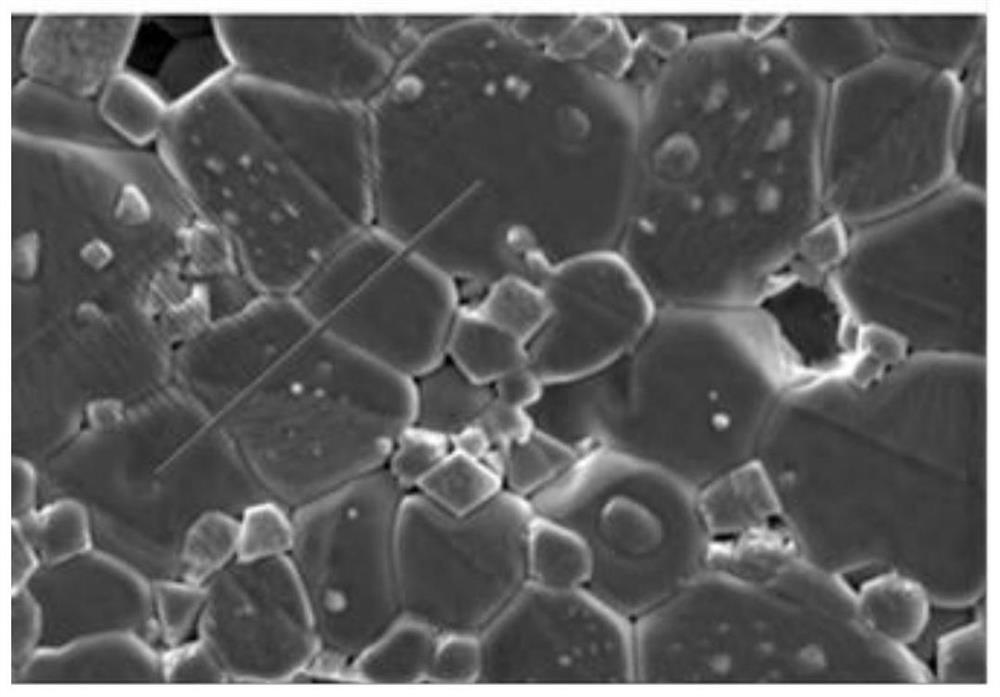

Image

Examples

Embodiment 1

[0034] A method for preparing a zinc oxide resistance sheet 1 capable of reducing the residual voltage ratio, the steps are as follows:

[0035] a. Preparation of raw materials for zinc oxide resistors:

[0036] Calculate according to the mass percentage of components, adopt the following raw material formula to prepare raw materials:

[0037] ZnO: 87.825wt.%, Bi 2 o 3 : 3.8wt.%, Sb 2 o 3 : 1.7wt.%, Cr 2 o 3 : 1.2wt.%, MnO: 1.2wt.%, CoO: 2.4wt.%, SiO 2: 0.6wt.%, glass powder containing Ag and B: 1wt.%, Mg(AC) 2 : 0.25wt.%, Al(NO 3 ) 3 : 0.025wt.%;

[0038] b. Preparation of slurry:

[0039] b1. ZnO, Mg(AC) prepared in said step a 2 , Al(NO 3 ) 3 Mix it with deionized water to form a slurry, add it to the slurry tank and stir for 30 minutes, dry the mixed slurry and pulverize it into powder;

[0040] b2. The mixed powder material obtained in the step b1 is pre-calcined at a temperature of 950 ° C for 2 hours to promote part of the Al 3+ and Mg 2+ The ions penet...

Embodiment 2

[0055] The preparation method of the zinc oxide resistance sheet 2 that can reduce the residual voltage ratio, the steps are as follows:

[0056] a. Preparation of raw materials for zinc oxide resistors:

[0057] Calculate according to the mass percentage of components, adopt the following raw material formula to prepare raw materials:

[0058] ZnO: 87.575wt.%, Bi 2 o 3 : 3.8wt.%, Sb 2 o 3 : 1.7wt.%, Cr 2 o 3 : 1.2wt.%, MnO: 1.2wt.%, CoO: 2.4wt.%, SiO 2 : 0.6wt.%, glass powder containing Ag and B: 1wt.%, Mg(AC) 2 : 0.5wt.%, Al(NO 3 ) 3 : 0.025wt.%;

[0059] b. Preparation of slurry:

[0060] b1. ZnO, Mg(AC) prepared in said step a 2 , Al(NO 3 ) 3 Mix it with deionized water to form a slurry, add it to the material bucket and stir for 30 minutes, dry the mixed slurry and pulverize it into powder;

[0061] b2. The mixed powder material obtained in the step b1 is pre-calcined at a temperature of 950°C for 3 hours to promote part of the Al 3+ and Mg 2+ The ions pe...

Embodiment 3

[0076] The preparation method of the zinc oxide resistance sheet 3 that can reduce the residual voltage ratio, the steps are as follows:

[0077] a. Preparation of raw materials for zinc oxide resistors:

[0078] Calculate according to the mass percentage of components, adopt the following raw material formula to prepare raw materials:

[0079] ZnO: 85.372wt.%, Bi 2 o 3 : 4.2wt.%, Sb 2 o 3 : 2.3wt.%, Cr 2 o 3 : 1.0wt.%, MnO: 1.2wt.%, CoO: 2.4wt.%, SiO 2 : 1.0wt.%, glass powder containing Ag and B: 1wt.%, Mg(AC) 2 : 1.5wt.%, Al(NO 3 ) 3 : 0.028wt.%;

[0080] b. Preparation of slurry:

[0081] b1. ZnO, Mg(AC) prepared in said step a 2 , Al(NO 3 ) 3 Mix it with deionized water to form a slurry, add it to the material bucket and stir for 30 minutes, dry the mixed slurry and pulverize it into powder;

[0082] b2. The mixed powder material obtained in the step b1 is pre-calcined at a temperature of 1000 ° C for 3 hours to promote part of the Al 3+ and Mg 2+ The ions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com