Hydraulic device for feeding back output torque of power assisting servo motor by utilizing self-weight potential energy

A technology of servo motor and output torque, which is applied in the field of servo motor to achieve the effect of increasing output torque, strengthening auxiliary output capability, and reducing consumption frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

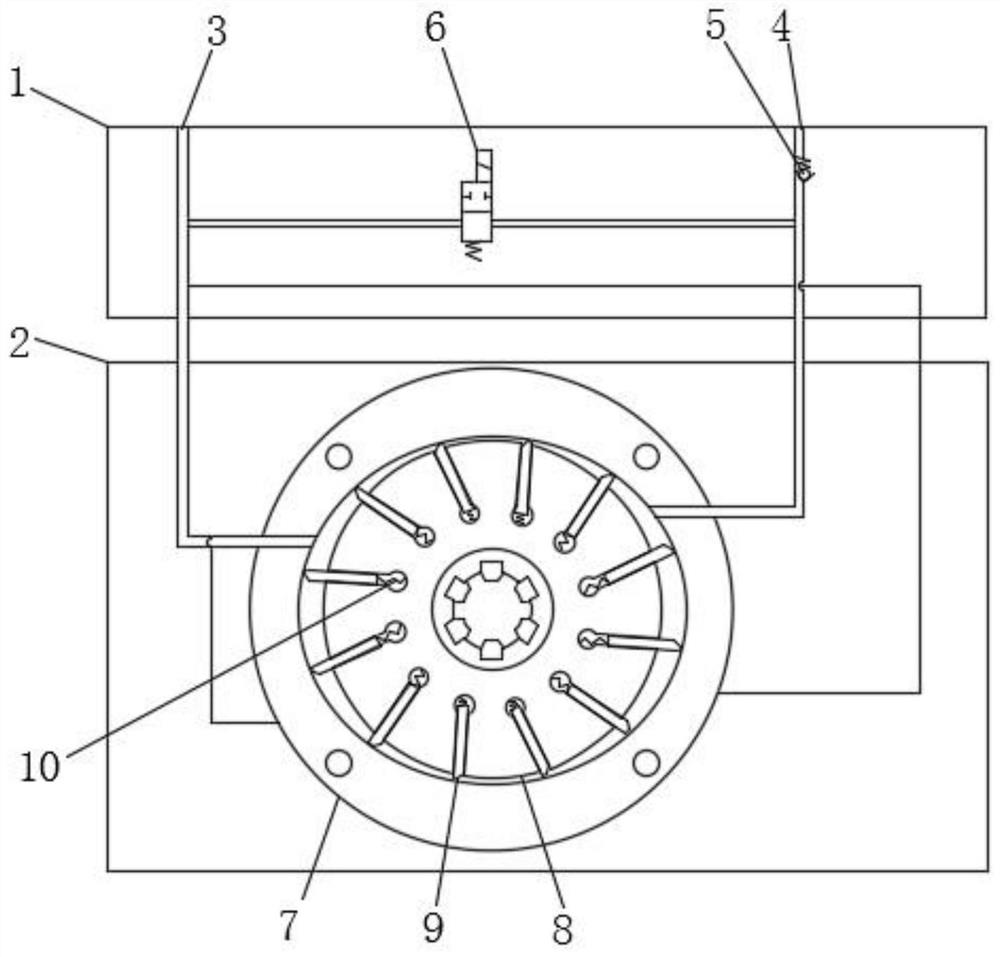

Embodiment 1

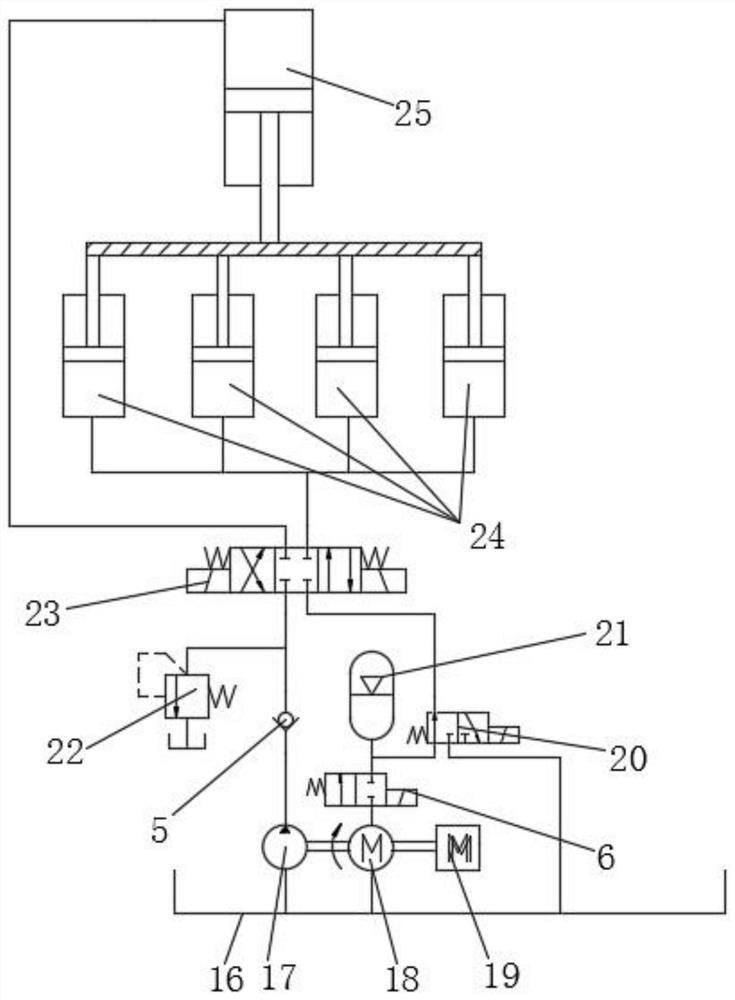

[0036] Example 1, such as image 3 As shown, take a certain pressure as an example;

[0037] (1), the original use of 45KW servo drive, 50KW servo motor, 80cc+80cc double variable speed hydraulic pump.

[0038] (2) The main oil cylinder is a single-acting oil cylinder with a bore of 510mm, a stroke of 1600mm, and a maximum working pressure of 25Mpa.

[0039] (3) Ascending auxiliary cylinder single-acting oil cylinder, bore 120mm, stroke 1600mm, 4 cylinders connected in parallel.

[0040] (4) The self-weight descending accumulator of the main oil cylinder can recover hydraulic energy above 72L / min.7Mpa from the ascending auxiliary cylinder.

[0041] (5) The power assist mechanism is designed with a displacement of 200CC, and the accumulator recovers 72L / min.7Mpa hydraulic energy, which can provide an output torque of 200N / m, and can provide torque assist for 9 seconds at a maximum volumetric efficiency of 80% at 2000 rpm.

[0042] (6), the above conditions show that increasi...

Embodiment 2

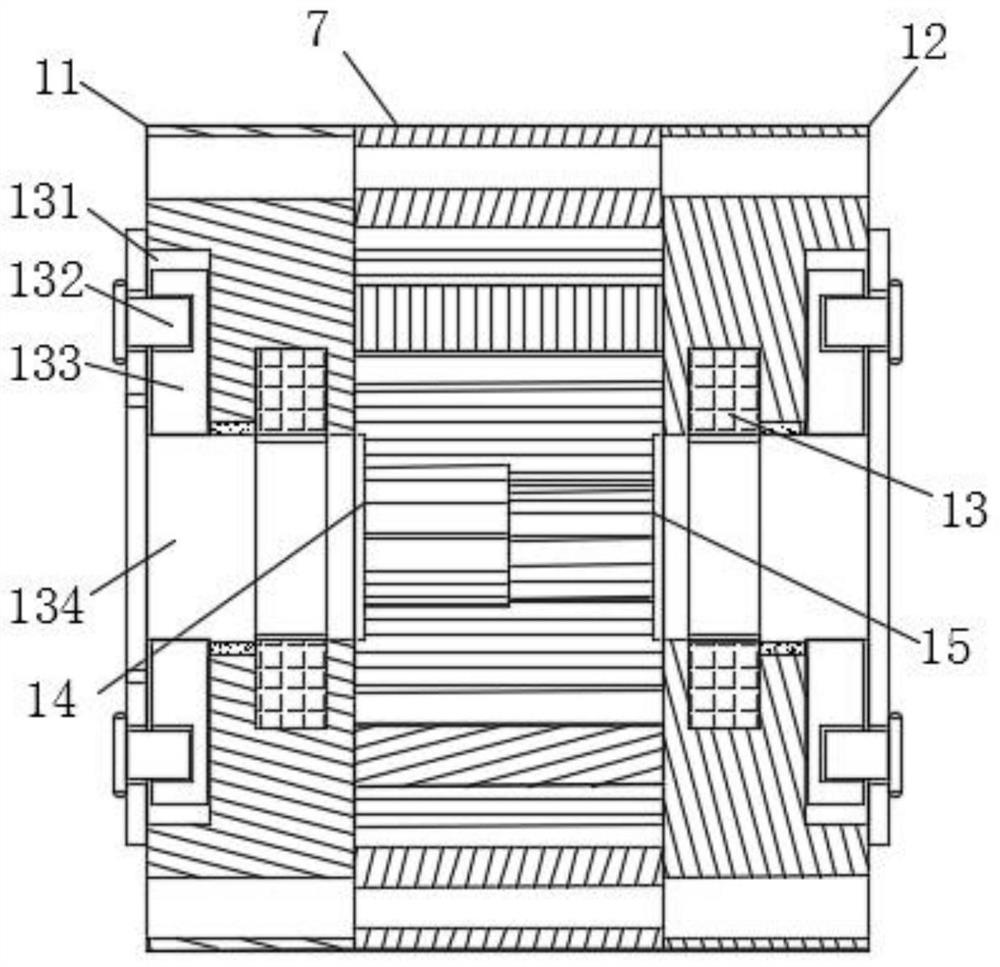

[0043] Example 2, such as Figure 4-5 As shown, when the variable speed hydraulic pump 17 and the servo motor 19 are disassembled, the spline bushing 134 can drive the four sets of positioning plates 133 into the arc groove 131 in advance, and the movement of the spline bushing 134 can be used to drive The rotating oil seal 13 seals the interior of the stator 7, and then the splined bushing 134 drives the positioning plate 133 to move in the arc-shaped groove 131, so that the positioning plate 133 moves to a designated position, and the positioning plate 133 is fixed by the fixing pin 132, And then the output shaft of the variable speed hydraulic pump 17 and the servo motor 19 is installed, and the sealing effect in the stator 7 is increased to prevent the oil from leaking when the motor is in operation.

[0044] Working principle: when the press is descending, the self-weight potential energy generated by the descending of the press is recovered and stored through the accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com